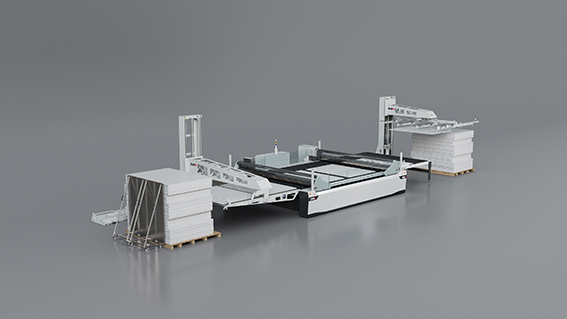

With an event at its headquarters in Altstätten in Switzerland, on April 19 and 20 Zünd presented the new Q-Line with Board Handling System BHS180 and Undercam, redefining the standards of “pallet-to-pallet” digital converting. A top-of-the-range technology that does not replace previous generation cutting plotters but is aimed at a highly productive market with new-concept machines

There was great wait for the launch of the new digital cutting plotters by Zünd, which last April, in the presence of the most important European sector magazines, among which Converter could not miss out, unveiled the latest technological jewel that was entirely designed and built in the heart of Switzerland, in Altstätten, a few kilometers from St. Gallen and Lake Constance, a very fascinating landscape location where the Swiss manufacturer of digital cutting systems has its headquarters, a large and modern building, built a few years ago already with a view to sustainable production, and where excavations have already begun for the expansion of the production site, which will be ready in the summer of 2026 and will be dedicated specifically to the construction of the new Q- line.

Oliver Zünd with company’s top management presented the technical characteristics and the idea behind the latest generation plotters, designed for productivity pushed beyond the normal potential of digital technology. A surrogate of technology and automation, the one that gave birth to the new Q-Line with BHS180 which will be able to support companies that produce corrugated cardboard displays, with fully automatic workflow management from pallet to pallet. In between, a whole series of new technologies for non-stop production, under control, at high speeds and with exceptional quality standards. The quality of Zünd digital cutting tables is entirely born internally, where starting from the selection of the most innovative materials, such as the epoxy granite bases that give solidity to the structure, the carbon fiber used on the bars where are inserted cutting heads, everything is taken care of down to the smallest detail, and where each machine is assembled, tested and finally disassembled again to be shipped to the customer, with a lean production view.

Oliver Zünd with company’s top management presented the technical characteristics and the idea behind the latest generation plotters, designed for productivity pushed beyond the normal potential of digital technology. A surrogate of technology and automation, the one that gave birth to the new Q-Line with BHS180 which will be able to support companies that produce corrugated cardboard displays, with fully automatic workflow management from pallet to pallet. In between, a whole series of new technologies for non-stop production, under control, at high speeds and with exceptional quality standards. The quality of Zünd digital cutting tables is entirely born internally, where starting from the selection of the most innovative materials, such as the epoxy granite bases that give solidity to the structure, the carbon fiber used on the bars where are inserted cutting heads, everything is taken care of down to the smallest detail, and where each machine is assembled, tested and finally disassembled again to be shipped to the customer, with a lean production view.

The new Q-Line with Board Handling System – BHS180 in detail

Undoubtedly one of the main novelties introduced by Zünd engineers on this new line is the UNDERCAM (or camera from below) integrated in the sheet feeder which detects the image printed on the sheet and recognizes any deformation of the print, guaranteeing at any time a perfect match between print and cut data. With each scan, the software adjusts the cutting contours to the printed image on the fly and in real time. In this way it is possible to significantly reduce the cycle time of each order.

Undoubtedly one of the main novelties introduced by Zünd engineers on this new line is the UNDERCAM (or camera from below) integrated in the sheet feeder which detects the image printed on the sheet and recognizes any deformation of the print, guaranteeing at any time a perfect match between print and cut data. With each scan, the software adjusts the cutting contours to the printed image on the fly and in real time. In this way it is possible to significantly reduce the cycle time of each order.

During the sheet feeding phase, the sensors recognize the edges of the material, allowing the sheet to be oriented correctly. If the sheet is outside the tolerance range, the feeder grabs it and realigns it, so that it is conveyed to the cutter without causing interruptions to the process. In this way it is also possible to work stacks that are not perfectly aligned, guaranteeing even more stable production. Depending on the material and individual requirements, the Zünd Cut Center – ZCC allows you to set innovative suction cups which ensure even more reliable separation of the sheets.

The new design of the take-up unit allows you to stack simply and cleanly cut sheets without vertical sides. The picking unit stacks the various orders with a lateral deviation, so that completed jobs can be removed from the stack simply and cleanly for further processing. Even any defective sheets are deposited with a lateral deviation, making them clearly visible when the pallet is picked up.

Furthermore, the possibility of stacking cardboard up to a height of 180 cm, as well as allowing high productivity in the case of long runs, also allows the management of various orders, which are recognized thanks to the QR Codes printed on the sheet to be cut, but outside the print area, which communicate the cutting path information to the machine, which, once the job has been processed, will stack it slightly deviated in the final stacker compared to the previous job. This allows you to manage different graphic layouts and find them stacked at the end, divided by job, without having to download each job every time.

Furthermore, the possibility of stacking cardboard up to a height of 180 cm, as well as allowing high productivity in the case of long runs, also allows the management of various orders, which are recognized thanks to the QR Codes printed on the sheet to be cut, but outside the print area, which communicate the cutting path information to the machine, which, once the job has been processed, will stack it slightly deviated in the final stacker compared to the previous job. This allows you to manage different graphic layouts and find them stacked at the end, divided by job, without having to download each job every time.

In addition to the hardware, it also includes comprehensive services, intuitive and simple software, such as the latest version 4.0 of the Zünd Cut Center – ZCC control software or the Zünd Connect analysis and monitoring tool, and a wide range of consumables. The workflow is another distinctive element for Zünd which in fact, thanks to its team of engineers, has developed a series of cloud-based tools capable of following the company from administration to the delivery of the finished work, with a series of technical tools capable to intervene before the printing and finishing phase, so as to be able to make all the necessary corrections and have a flow totally under control in each phase.

Digital tool management

The tool management of the Q-Line with BHS180 has also been redesigned to increase automation. In fact, the new generation of Q-Line cutters is equipped as standard with automatic tool change systems. The entire tool management takes place via TOMAC Tool Management Client, which guarantees simple and above all automated processes. Digital interconnection of tool setting and mounting optimizes tool management and saves valuable time by avoiding possible human errors.

There are 2 tool magazines on board and each is able to accommodate up to 7 tools. Furthermore, as the technicians repeatedly pointed out during the presentations, although Zünd machines can also be equipped with compatible blades produced by third-party suppliers, the use of original Zünd-branded cutting blades with unique codes, in addition to being a guarantee of optimal performance, allows you to match that single blade to a specific job and get the precise number of hours that the blade has worked on the machine, thus providing useful data to plan and optimize tool replacement interventions.

A solid structure to guarantee high speeds and an attractive and winning design

The completely new mechanical model behind the Q-Line with BHS180 redefines the performance limits on all fronts.

The new machine components together ensure astonishing speeds of up to 2.8 m/s. The innovative structure at the base of the Q-Line cutter is made of highly stable epoxy granite and can guarantee a fluid course and maximum cutting precision even at high speeds. The production arms are made in reinforced plastic material with carbon fiber, which increases their lightness and strength.

This allows you to work even the most demanding materials at maximum speed and with the highest quality. The product’s unique performance is also manifested in its impressive acceleration capabilities (up to 2.1 g) made possible by the new linear drive system. In this way, very high processing speeds are achieved, significantly reducing the cycle times for each single job.

Finally, to protect the operator during production, when the machine is running, two plexiglass barriers rise to the sides. If desired, these barriers can remain lowered but in this case the speed of the machine is automatically reduced so as not to constitute a danger to the operator.

All these small details, which are essential elements that contribute to the correct functioning of the system, together with a modern and captivating design, have contributed to the victory of the Red Dot award for the Q 32-32 D model, an international acknowledgment: in the case of the new Zünd plotter, the jury particularly appreciated an innovative design that gives this new technology an unmistakable style. In short, even the eye wants its part and here I would say that it has been largely satisfied.