The new machine “fully meets our demand for top quality at high speed regarding the packaging of films converted in our Skarbimierz Osiedle plant”

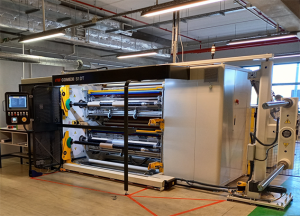

Comexi and Wipak Polska, a company specialising in the manufacture of bags and the conversion of films supplied by other Wipak Group companies, have reached an agreement for the acquisition of a Comexi S1 DT slitter by the Polish company. Quality, high productivity, and incorporated safety measures are the primary reasons for the acquisition of a second Comexi S1 DT slitter by Wipak Polska; the first machine of this type was purchased in 2017.

“The Comexi S1 DT slitter is a machine that fully meets our demand for top quality at high speed regarding the packaging of films converted in our plant,” explains Wlodzimierz Glapa, managing director of Wipak Polska. The arguments that convinced the Polish company to purchase a second slitter, identical to the 2017 machine, are “firstly, safety, as the machine is equipped with all the necessary measures that protect our employees from injuries and safety incidents. Furthermore, the operation of the Comexi S1 DT slitter is straightforward and intuitive. The second reason for the purchase references the machine’s quality, which concurs with high productivity of the slitting process.”

“The Comexi S1 DT slitter is a machine that fully meets our demand for top quality at high speed regarding the packaging of films converted in our plant,” explains Wlodzimierz Glapa, managing director of Wipak Polska. The arguments that convinced the Polish company to purchase a second slitter, identical to the 2017 machine, are “firstly, safety, as the machine is equipped with all the necessary measures that protect our employees from injuries and safety incidents. Furthermore, the operation of the Comexi S1 DT slitter is straightforward and intuitive. The second reason for the purchase references the machine’s quality, which concurs with high productivity of the slitting process.”

Wipak has been present in Poland for many decades, serving its customers with sales and distribution. In 2013, the company relocated to Skarbimierz Osiedle, establishing a new production site. This facility is dedicated to the manufacturing of pouches and convert films supplied by other Wipak plants. Since this moment, Wipak Polska has increased its productivity and capabilities, thus strengthening its position as a flexographic printing hub within the Wipak Group. The company primarily serves the food and healthcare sectors. The products of Wipak Polska are designed to provide maximum protection capacity while being at the forefront of this type of innovative sustainable packaging.

The Comexi S1 DT is a slitter that provides excellent quality and productivity results, even in regard to the most demanding jobs, due to its state-of-the-art control elements and high degree of automation. As a result of an extremely interactive and easy-going user interface, almost every adjustable element of the machine, including cores, knives, laser heads, and photocells, are self-calibrating. Without the need to intervene, this unique automation of the Comexi S1 DT allows the operator to load the reel into the machine and deliver finished reels.

The turreted version of the Comexi S1 DT is capable of performing jobs that require numerous output reels. Additionally, it is operable with the thickest materials used in the flexible packaging market, including aluminium, wax, and other special or complex materials. The Comexi S1 DT allows for a high degree of customization, as well as many automated options, such as splicing tables, automatic reel unloading, video camera inspection, and label robotization of finished reels. It fully guarantees complete system control and has an exceptional productivity increase.

Wipak Polska is part of the Wipak Group, a Finnish global supplier of premium quality, sustainable, and innovative flexible packaging solutions for food, medical devices, and pharmaceutical products. Witrh 11 manufacturing plants across Europe, the Wipak Group and Comexi began their relationship in 2005, when the Finnish company acquired the first Comexi slitter. The purchase of other laminators and slitters has subsequently strengthened the confidence between the two companies.