Based in Italy, Vega Srl, the manufacturer of folder gluers, has recently concluded an important deal that sees them buying the brand, patents and know-how of the Revicart Company. “I have long hoped for a kind of synergy between our two companies, but the time was never quite right, but when the opportunity arose back in July, we didn’t miss the opportunity,” says Dr. Jacopo Nava, Vega’s Managing Director. During the CCE

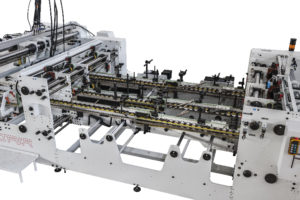

Show in Munich, Vega will exhibit the integration in their lines of the Revicart collecting systems, which complete any request or need the customer would have for the automatic collecting. The VEGA EASYPACK, the PACK 120/T1/T2 and the ROTOPACK are the 3 counting, automatic separation and parcels binding chances of the folded and glued boxes coming out from the folder gluer. The end line completes the range of solutions put in place by Vega after the Double Feeder Vega ADF and the Folder Gluer Vega ALTAIR. With the recent acquisition of Revicart skills and patents and of its experience in combining the Double Feeder with dozens of other brands folder gluers, Vega presents itself on the market as a Leader of this technology and as a supplier of different multiple feeding solutions according to the customer’s needs.

According to this, Vega will present on the market the folder gluer integrated to the Double Feeder, the VEGA ALTAIR-ADF, available in 4 sizes, 160-200-240-290cm, manufactured in Italy. This model, constantly upgraded, has been conceived in modules: giving the Customer a free and a continuing choice even after the installation.

According to this, Vega will present on the market the folder gluer integrated to the Double Feeder, the VEGA ALTAIR-ADF, available in 4 sizes, 160-200-240-290cm, manufactured in Italy. This model, constantly upgraded, has been conceived in modules: giving the Customer a free and a continuing choice even after the installation.

The Double Feeder VEGA ADF is offered in integrated or independent (on rails) version, because for some applications the ADF can work without the presence of the folder gluer (TV, mattresses, automotive boxes….).

The Double Feeder, unique solution on the market, can be equipped with the Braille device in order to emboss Braille dots on the solid board display half of Quick Easy Top box. After the joining of multiple pieces boxes, each single blank goes into the Vega ALTAIR folder gluer for the next folding/gluing operations. The Vega Altair, in its modular configuration, is conceived for high quality productivity through the presence 8 quality elements.: the creasing carriages in the closing section, the lateral squaring in the middle of the closing section, the squaring units at the delivery section and in front of the collector, the spanker system (like “case maker” for the American boxes) and the back kicker for big and large crash lock bottom boxes. A quality assurance device is detecting any faulty box and an Inline Box Ejection Module allows the underneath ejection of each not conformity box. A couple of motorized pressing Rollers are pressing the box surface after the folding and gluing before the pressure belt. The servomotors independently motorize every module.

The Double Feeder, unique solution on the market, can be equipped with the Braille device in order to emboss Braille dots on the solid board display half of Quick Easy Top box. After the joining of multiple pieces boxes, each single blank goes into the Vega ALTAIR folder gluer for the next folding/gluing operations. The Vega Altair, in its modular configuration, is conceived for high quality productivity through the presence 8 quality elements.: the creasing carriages in the closing section, the lateral squaring in the middle of the closing section, the squaring units at the delivery section and in front of the collector, the spanker system (like “case maker” for the American boxes) and the back kicker for big and large crash lock bottom boxes. A quality assurance device is detecting any faulty box and an Inline Box Ejection Module allows the underneath ejection of each not conformity box. A couple of motorized pressing Rollers are pressing the box surface after the folding and gluing before the pressure belt. The servomotors independently motorize every module.

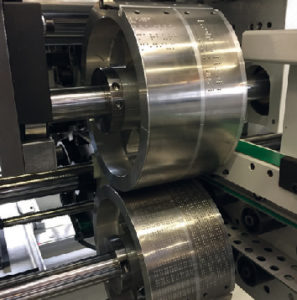

Vega has introduced a new technology for the folding of Crash Lock Bottom, 4 and 6 Corners at HIGH SPEED. This new system uses lower hooks mounted on two lower shafts driven by two independent brushless motors which allow the folding of the frontal flaps of the 4/6 corners and crash lock bottom boxes without using the upper mechanical hooks. This guarantees to reach high level of production because the gap among the boxes in the machine is considerably reduced and the speed of the mechanics of the machine can be brought to maximum levels. The use of this new technology reduces the maintenance costs, by not using the mechanic upper hooks and it reduces the make ready time.

Vega has introduced a new technology for the folding of Crash Lock Bottom, 4 and 6 Corners at HIGH SPEED. This new system uses lower hooks mounted on two lower shafts driven by two independent brushless motors which allow the folding of the frontal flaps of the 4/6 corners and crash lock bottom boxes without using the upper mechanical hooks. This guarantees to reach high level of production because the gap among the boxes in the machine is considerably reduced and the speed of the mechanics of the machine can be brought to maximum levels. The use of this new technology reduces the maintenance costs, by not using the mechanic upper hooks and it reduces the make ready time.

In addition to the above, the most sophisticated and advanced Revicart quality control systems have been integrated in the Vega Folder Gluers, giving further interest to the Italian company’s portfolio. The Munich Exhibition will be the chance to present these innovations on the market and in particular the combination of these two companies technologies.