Let’s find out how the software innovation at the base of digital transformation allows us to concretely improve the relationship between packaging producers and brand owners

Valtenna was born in the 1960s in Fermo in Marche region, as an artisan workshop for the production of rigid covered shoe boxes; the change of pace took place in the 90s, with the generational change and the expansion of the production offer aimed at developing versatile and advanced solutions for folding boxes and corrugated cardboard packaging. Reasoned strategic choices that lead Valtenna to become one of the very few Italian cardboard converting companies to offer a complete range of products with high quality standardization and high flexibility of processes and volumes.

Valtenna was born in the 1960s in Fermo in Marche region, as an artisan workshop for the production of rigid covered shoe boxes; the change of pace took place in the 90s, with the generational change and the expansion of the production offer aimed at developing versatile and advanced solutions for folding boxes and corrugated cardboard packaging. Reasoned strategic choices that lead Valtenna to become one of the very few Italian cardboard converting companies to offer a complete range of products with high quality standardization and high flexibility of processes and volumes.

A modern industry that has been able to manage the transition from craftsmanship to industry 4.0 with the attitude of a leader. The use of the most innovative technologies that guarantee the maintenance of high quality standards for a very demanding and increasingly international clientele, the automation of all production processes, an efficient and fluid internal organizational model are the main strengths that make Valtenna a reliable and flexible partner.

The results of these choices testify to the success story of a company in constant growth since its foundation, 25 million turnover in the last year, about 120 employees distributed in four production sites, more than 16,000 orders processed each year and 57 million pack products.

The skills gained in almost 60 years of activity have allowed the company to evolve with a synergic vision, creating two divisions. Each of them has dedicated production lines and is part of an integrated company management in which data, information, processes, controls, supply, logistics, research and development converge.

This technological ecosystem represents Valtenna’s commitment to guaranteeing product and processing versatility, quality, problem solving and reliability. The technological equipment includes flexographic and offset printing, screen printing, hot or dry printing for finishing, lamination, die-cutting, both automatic and manual set-up and packaging with variable data.

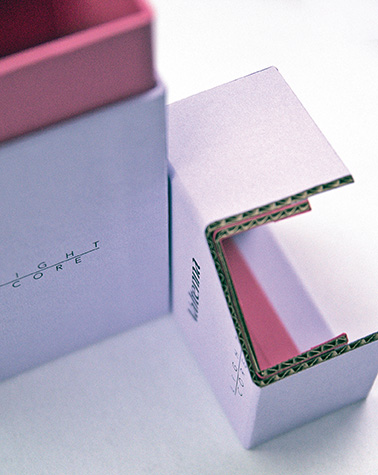

The historical division, Packaging Rigido, specialized in the production of high added value coated cases and boxes, has undergone profound transformations over time. Today it boasts fully automated, elaborate and complex processes, while maintaining a high degree of customization. The high quality and attention to details meet the demands of customers who are positioned in the luxury sector.

The historical division, Packaging Rigido, specialized in the production of high added value coated cases and boxes, has undergone profound transformations over time. Today it boasts fully automated, elaborate and complex processes, while maintaining a high degree of customization. The high quality and attention to details meet the demands of customers who are positioned in the luxury sector.

The Cartotecnico Packaging division is focused on the production of folding boxes and cases in corrugated cardboard. The start of this production represents a fundamental turning point for the business because it offered Valtenna the possibility not only to differentiate the product offer but also to interface with high-end brands in the fashion, cosmetics, food, accessories sectors.

The investments in recent years in support of industry 4.0 have made it possible to optimize not only the dialogue between the various corporate, commercial, administration, production, logistics functions, but also to offer its customers a series of additional services that are always oriented towards a more agile management of processes. Logistics warehouses that allow storage, pick-up and distribution services in Italy and abroad, latest generation IT systems to share data relating to the progress of orders in real time, verticalization of e-procurement systems on the individual customer to manage both retail and industrial production and logistics needs. All in the name of standardization of quality and great flexibility in volumes and processing.

When begins the relationship between Valtenna and B + B

The history of Valtenna is apparently similar to that of many Italian small-medium enterprises. The background is that of the beautiful Marche countryside which, in the 1960s, underwent a profound transformation of the local productive asset which passed from purely agricultural and artisanal to industrial. At the beginning of the 90s the gradual generational change begins and the children of the founders enter and immediately bring the first innovations, including the adoption in 1998 of Packway management software, specific for the packaging sector. Packway originally covered only a few areas of management, mainly order and billing. Step by step have been added production planning, data collection from the machine, management of warehouses and shipments, the commercial CRM and the management of the technical office, the various interconnections in a 4.0 perspective with the new machinery and recently the innovative Packway E-Procurement portal.

Another very important step in 2005 was the establishment of an internal technical office, with the inclusion of ArtiosCAD design software and the first Kongsberg XL20 plotter, always supplied by B+B, to increase design reactivity, propose always new solutions to requests of customers and approach the production of cardboard boxes. In fact, the services offered to the customer, design of geometries and volumes, prototyping, represent the keystone for the growth of the company, which strengthens its problem-solving skills and innovative creative proposals.

Another very important step in 2005 was the establishment of an internal technical office, with the inclusion of ArtiosCAD design software and the first Kongsberg XL20 plotter, always supplied by B+B, to increase design reactivity, propose always new solutions to requests of customers and approach the production of cardboard boxes. In fact, the services offered to the customer, design of geometries and volumes, prototyping, represent the keystone for the growth of the company, which strengthens its problem-solving skills and innovative creative proposals.

Attentive to the territory in which it was born and raised, Valtenna has always implemented virtuous policies and behaviors aimed at respecting the territory and human capital. The process for obtaining the certifications begins in 2004 with ISO 9001-2000 and continues in 2011 with the FSC® and PEFC, which ensure customers the use of wood materials coming exclusively from sustainable, economically ethical and socially right collections.

Ethical, environmental and social responsibility is also underlined with SA8000 certification of social responsibility. Valtenna recently obtained the certifications: ISO 14001, ISO 45001. All the above-mentioned certifications are completely managed with Packway management software.

Face to face with management of Valtenna

What were the needs that led you to the Packway E-Procurement portal?

“Previous to Packway e-Procurement, third-party software was used, completely disconnected from the management of our company, which created operational difficulties both for the customer who had to enter orders and manage the recall of deliveries” blindly “, that is, without references to coded articles, without information on stocks or on orders already in place, generating considerable operational difficulties for users who had to write down or remember their order situation at our company, and for us as all orders had to be entered manually. With the adoption of Packway E-Procurement, on the other hand, everything is integrated and automated, each operation is guided to avoid entering inconsistent orders or delivery requests. In this way we were able to extend the functionality of our management software to our customers, actively involving them in the order process and related deliveries.

In this way, all the production subcontractors of brand owners are also managed, who become key players in the system to optimize processes and build the true “Extended Enterprise”, to create value for the market together with its own customers and suppliers.

Packway E-Procurement helps us to reduce all those telephone or email communications between customer and supplier that are already fully answered by consulting the platform, thus avoiding latencies and decreasing response times to the various queries that are requested daily. Customers can know in real time the progress of their orders, including our internal production phase, to better plan their work.

The issue of information transparency is an aspect that we are strongly involved in, because we believe it is a fundamental element in the relationship between customer and supplier in order to improve the performance of all stakeholders in the supply chain. Transparency goes hand in hand with promptness in providing, or rather in giving the correct information, always and quickly, to the right interlocutor”.

But what exactly is Packway E-Procurement?

“Packway E-Procurement is the new web platform developed entirely by B+B, which allows the automation of the order management process, between customer and supplier, creating a strong interaction and consolidating the links between companies to be able to create value for themselves and for the market.

“Packway E-Procurement is the new web platform developed entirely by B+B, which allows the automation of the order management process, between customer and supplier, creating a strong interaction and consolidating the links between companies to be able to create value for themselves and for the market.

The technologies used allow both manual operation through a simple and modern interface, but above all the ability to integrate and communicate with different management systems, Packway with SAP for example, which normally could not communicate. This without having to type the data manually, but taking and delivering them directly to the management system of each respective company, automating processes, speeding up operational flows and thus eliminating the possibility of errors that would have an impact on the entire production process. In addition to translation of data, Packway E-Procurement allows you to have complete and timely traceability of every single operation performed on the platform, to recall in maximum detail all the activities that took place in the management of an order or its delivery.

It is evident how much these automatisms decrease or eliminate all low added value phases that we have to carry out every day in our companies”.

How was the Packway E-Procurement project managed and what role did the end customer play?

“The approach used by B+B for project management saw us involved from the very early stages of the analysis that we developed with the involvement of the various customer operational divisions.

The lean-agile methodology used refers to an innovative and interactive software development concept that puts the customer at the center of the project. We worked by breaking down the activities into various well-defined phases, thus making it possible to carry out development and test activities simultaneously and to carry out multiple checks with our customers during the entire life of the project.

We felt at the center of operations, involved in every phase more as active protagonists than as customers, collaborating extensively and directly with the entire project team throughout the duration of the works.

Undoubtedly very much appreciated the fact of having had the opportunity to see the evolution of the portal during the various stages of progress and to make decisions/changes in itinere that allowed us to get to the end with a truly ready and operational ad hoc solution”.

How do you intend to extend this service to other customers?

“Now that the Packway E-Procurement portal is consolidated it will be possible to extend the same process to other customers and in other sectors. By increasing the number of users, we will be able to make our organization more and more efficient and strategically consolidate the relationship between customer and supplier. According to our point of view, the sectors that are most suitable for these dynamics are those linked to the sector of luxury packaging, industry, food and the world of retail.

Through the directional analysis on Microsoft Power BI it is also possible, both for us but also for our customers, to view reports that immediately extract the necessary information. This is a very important added value that can potentially be extended to all our customers”.

What advantages does Packway E-Procurement bring to your company and your customers?

“The possibility of obtaining an order loaded automatically in your management system generates a series of very significant advantages. First of all, a cost advantage by not having to load the order manually, the standardization of order management process helps to reduce misunderstandings and any inefficiencies with customers. The interactivity of the platform, the transparency with which we give important information for the customer and the timeliness of the data drastically reduce all those communications with low added value that we have daily with our customers, making them autonomous in verifying, when they need, important information to optimize their production process.

Getting an order into a system without having to re-type the data helps us not to make mistakes and frees people from repetitive operations that no longer make sense with today’s technological equipment.

Another huge advantage that the platform has given us is that of being able to customize the operational constraints for each customer, effectively making the system like a tailored suit that manages a standard process. Each customer finds their own rules, their own customizations which are then brought back to the company standard, without having to spend time each time for any management reconciliations of incorrect data”.

What could be the next implementations for Valtenna?

“We do not hide the fact that the company intends to make major investments during the current year, including the installation of a new offset printing machine. In relation to these investments, we intend to strengthen our pre-press department and increase the depth of integration between our Packway management software and prepress software, to be able to make the artwork visible directly in the E-Procurement portal.

We will certainly continue to increase the number of users, both among our customers but also among our suppliers, with the aim of consolidating supply chain partnerships that will allow us to increase the global value of the supply chain”.