Unicarton, a manufacturer of heavy corrugated cardboard packaging, installed a new digital cutting plotter by Zünd at the beginning of the year, which is opening up new development prospects for the Veneto box manufacturer

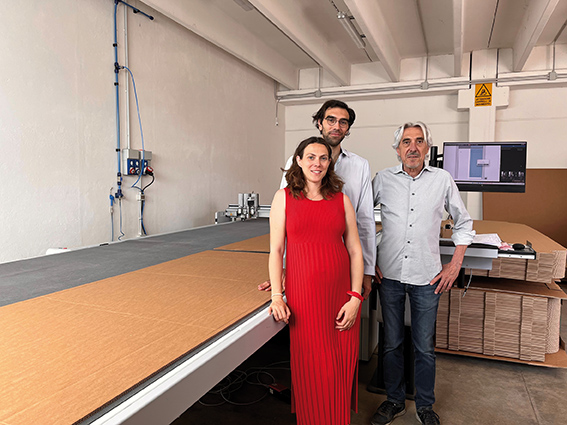

When things get tough, or as in this case heavy, the best solutions and products capable of solving problems come into play. This sentence fits perfectly when talking about Unicarton, a family-run box factory in Rovigo, with 10 collaborators, active on the market since 1998, and today managed by its founder Danilo Tosato, with loads of senior experience in the packaging sector, supported by his children Matilde, who, since 2017 is Administrative and Management Manager and Giulio, Technical Sales Manager specialized in Packaging Design.

From the start Unicarton’s distinctive element was the decision to serve the local market, an industrial sector that requests heavy, high-performance packaging for long transport chains: these industries found their point of reference in this reality.

Considering Unicarton’s strong orientation towards design, carried out more and more frequently in partnership with its customers, the company developed immediately a high-performance production line with water-based flexo printer slotter and in-line die-cutting, ideal technology for this type of market, used to big size packaging, that must be produced promptly, without obviously compromising the qualitative and functional aspect of the packaging.

Considering Unicarton’s strong orientation towards design, carried out more and more frequently in partnership with its customers, the company developed immediately a high-performance production line with water-based flexo printer slotter and in-line die-cutting, ideal technology for this type of market, used to big size packaging, that must be produced promptly, without obviously compromising the qualitative and functional aspect of the packaging.

Tailored packaging solutions

Unicarton serves a very demanding clientele, which requires tailor-made packaging solutions with high performance in terms of sealing and resistance, produced with highly resistant cardboard and ideal for maritime transport, on very long routes, subjected to strong stress, including climatic ones, especially humidity, for this reason Unicarton provides approved solutions for this specific need.

The range of Unicarton solutions includes the classic American boxes, self-assembling, wrapping and snap bottoms, clothes trunks, bottom with lids, hives and protective interiors, reels and die-cut boxes.

The new Zünd G3 XL-3200 plotter for small production batches

“In recent years we have seen a growing demand from our customers for flexibility in terms of production batches, with various delivery methods, which has led us to invest in a new, faster and more productive large format digital cutting plotter than the already present L-3000 model in 1850×3200 format, introduced in 2003 mainly for sampling needs, thanks to which we have become familiar and have also grown at a technical level and in our skills in converting sector. Furthermore, thanks to this first experience, we realized that digital cutting could represent a real resource, but we had to choose the right technology that would give us the opportunity to process large formats”, Matilde Tosato tells us, as evidence of how an investment in a high-performance technology is still within the reach of even small and medium-sized companies like Unicarton, which can in fact count on the support of a reference player like Zünd to be able to grow and develop in the packaging market.

The installation at the beginning of this year of the new Zünd G3 XL-3200 plotter was extremely strategic for the development of the business in Unicarton, which was able to promptly respond to the growing demand for flexibility from its customers, offering many sampling solutions, but also for all particular needs, last minute emergencies, which without a technology such as the Zünd digital plotter, would actually congest the traditional production line; not to mention the economic aspect, which, especially for single productions, would make the cost of the die unjustifiable from an economic point of view.

The installation at the beginning of this year of the new Zünd G3 XL-3200 plotter was extremely strategic for the development of the business in Unicarton, which was able to promptly respond to the growing demand for flexibility from its customers, offering many sampling solutions, but also for all particular needs, last minute emergencies, which without a technology such as the Zünd digital plotter, would actually congest the traditional production line; not to mention the economic aspect, which, especially for single productions, would make the cost of the die unjustifiable from an economic point of view.

“Thanks to the precision and speed of the new Zünd plotter, we can process production batches that we print in flexo and then cut digitally, with precision, speed and high-performance quality in both cutting and creasing.

“Thanks to the precision and speed of the new Zünd plotter, we can process production batches that we print in flexo and then cut digitally, with precision, speed and high-performance quality in both cutting and creasing.

The Zünd plotter gives us the possibility of processing other packaging materials such as honeycomb cardboard panels, allowing us to cut up to 50 mm thick material.

Experience on this type of machine allows us to explore new solutions and also open up to new markets. It’s the classic technology that when you don’t have it you almost don’t feel the need for it, at least for our type of work, but then when you use it and have it available you understand that you can no longer do without it”, adds Matilde, also making a parallel reflection on digital printing, which is not currently present in the company, but which in the future could also be taken into consideration to open up new business opportunities in sectors different from heavy industrial packaging.

“In these first months of use we are very satisfied with the investment made, and even if at the moment we have not yet reached full saturation, we do not rule out the possibility of equipping it in the future also with the automatic loading and unloading system, if necessary”, concludes Matilde.

“In these first months of use we are very satisfied with the investment made, and even if at the moment we have not yet reached full saturation, we do not rule out the possibility of equipping it in the future also with the automatic loading and unloading system, if necessary”, concludes Matilde.

Two special tools for the Zünd plotter chosen by Unicarton

The G3 XL-3200 is equipped with two particular tools: thanks to the Pneumatic Oscillating Tool-POT it is possible to work hard and resistant materials, thanks to the pneumatic control, combined with the 8mm blade stroke; while thanks to the Electric Oscillating Tool – EOT-250 it is possible to efficiently process sandwich panels and thick cardboard thanks to the 2.5mm blade stroke and its high oscillation frequency which allows faster processing.