Speeding up quoting was essential for Trocart, with ArtiosCAD Quotes & Orders the company has significantly increased the number of offers

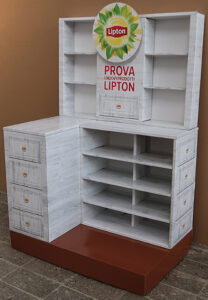

Trocart S.r.l has been operating in the packaging, display and digital printing sector since 1980, offering a service for the design and creation of unique “turnkey” display solutions. Technical and creative skills have allowed Trocart to combine paper processing with plastic materials, MDF, wood, metal, plexiglass, forex, dibond and any other material useful for satisfying market needs. In the historic headquarters in Cinisello Balsamo, are created displays and any type of communication material that can enhance the customer’s brand and the attention of the target audience.

Foresight, innovation and above all the continuous pursuit of customer satisfaction make Trocart a cutting-edge company that uses the most modern printing, cutting and milling technologies, paying attention to the environment.

Trocart uses an advanced material disposal system to limit pollution and waste, uses 100% biodegradable cardboard and recycled and recyclable raw materials. The storage and transport phase are also designed to limit space and waste as much as possible.

The company philosophy is to use the most recyclable materials possible: inks without chemical solvents and UV LED lamps for drying with low energy consumption. Great attention is also given to the recycling phase of materials, by using virgin-based paper, lamination is avoided by favoring gloss and matt finishes, to make every product delivered to the customer 100% recyclable.

Face to face with Diego Castelli and Loris Santolini – Owners of Trocart S.r.l.

How has the cardboard packaging market changed in recent years?

“Over the last few years we have been operating within a fiercely competitive context, the process of purchasing packaging and displays by our customers has changed, becoming increasingly organized with internal purchasing offices, average runs have dropped, requests of new projects / quotes have increased, while the desired response times have reduced.

Service, in the broadest sense of the term, commercial activity, design, quotation, production, logistics, is a key characteristic for the success of our company.

Digital printing or rather digital production is a form of manufacturing that is consolidating, but it requires a review of the entire way of doing business and understanding where to create new value.

Together with what was decisive for the birth of this sector, digital printing and cutting machines, there is a clear awareness that digital production is no longer the only critical success factor for our company but it is also necessary to have industrial, specific and integrated software that allows us to automate and control the entire production process, from briefing to order and delivery.

Digital transformation necessarily requires organizational adaptation and the insertion of new, fully integrated technologies, software and hardware.

Our customers demand increasingly rapid and qualitative response times, including estimates”.

How do you describe the current competitive scenario?

How do you describe the current competitive scenario?

“We are witnessing an exponential increase in the number of new projects requested by our customers, who on the one hand ask us to speed up the structural design and shorten the response time, but on the other also the possibility of quickly knowing the price of the conceived product, both because it very often must fall within a predefined budget, and because delivering the project or sample before the competitors is no longer sufficient, the selling price must also be communicated promptly.

Trocart produces increasingly complex packaging and displays, composed of multiple elements with different raw materials and different production cycles, for which the estimate was particularly complex, time-consuming and expensive from many points of view.

Until a few years ago, these activities were managed with non-integrated IT systems, generating many redundancies, manual data entry and risks of errors, requiring in-depth technical expertise often carried out by few resources, stressing the collaboration between the technical and commercial departments.

From this analysis we understood that designing well and quickly was no longer sufficient but it was also necessary to budget and manage all these processes with equal quality and timeliness.

An industrial management of pre-production activities, i.e. of all commercial, design, sampling, pre-press and above all estimating activities, was a necessity, as well as a key characteristic for the success of our company”.

What value do you see in ArtiosCAD Quotes & Orders?

“ArtiosCAD Quotes and Orders has given a very strong acceleration to the quoting activity, has simplified and drastically reduced the time to create an offer.

We were able to significantly increase the number of estimates with the same human resources, responding to customers significantly faster.

We have been using ArtiosCAD for structural design and Packway management software for a long time. By taking advantage of B+B’s two distinctive skills, that of ERP management software producers with that of experts in CAD/CAM technologies and the technical office, we were able to automate the creation of a quote directly from the CAD project through this new ArtiosCAD module.

The first great innovation was ArtiosCAD Canvas, a real turning point, allowing the design of a product made with multiple elements and different raw materials in a single worksheet, therefore in a single file. This design methodology allows you to develop a project in a single drawing and be able to attribute information such as the raw material, the production process, the die path for each individual element.

The SQL database has been extended to include a much wider range of information. It now contains data that is not only technical but also of a commercial and financial nature such as customer and supplier records, raw materials, internal and external work centers and equipment.

In this way we have combined all the technical aspects with the commercial ones, allowing you to obtain a technical data sheet, a quote or an order automatically from a CAD drawing.

The equally innovative feature is that there is no increase in activity for the designers, while for the estimators the work has been almost automated. The project is designed in ArtiosCAD, after which all information is automatically transferred to Packway generating a new data sheet. At this point the estimate is processed by Packway taking advantage of the uniqueness of its graphic technical data sheet, capable of managing all the raw materials and all the production phases, both of simple items, i.e. with a raw material and a linear production process, and of complex articles composed of several different raw materials with different formats, yields and production processes”.

How do you coordinate all pre-production activities?

“Pre-production management is coordinated by the Packway module called Docupoint.

The main objective was to use an information system capable of improving the service and quality of responses to the customer and at the same time optimizing the work of all the internal resources employed in the activities of the technical and commercial offices. Manage in an orderly manner what are commonly defined as internal orders, i.e. customer requests which do not actually constitute an order but which are preparatory to receiving the order. The strategic importance of managing all these activities well is clear. Initially we were looking for software for managing commercial activities, but we soon realized that a classic CRM was not enough, as Trocart does not offer catalog products, but rather every time we have to manage a new project, a tailor-made suit that must be developed based on the specific needs of the customer.

These conditions necessarily require constant and orderly dialogue between the various commercial and technical departments, hence the need to cover all these needs with a single software. Through the Docupoint Planner it is possible to have the situation of each activity under control, from technical design to sampling, from graphic design to estimating. People are more encouraged to collaborate and enter the correct information, paying more attention to the process. The master data, project data, accounting data and logistics data can be used from any platform as Docupoint is a Web system. In this way the salesperson who is away from the office or at the customer’s site can have all the necessary information available, in real time. Furthermore, one of the main strengths of Docupoint is that it can produce reports that can be viewed with Excel or Microsoft Power BI. This is useful information for understanding how many projects are developed, how many revisions are made, how many requests become orders, analyzing the reasons in an analytical way. In addition to the possibility of creating a technical sheet or estimate directly in Packway, the great innovation expressed in Packway Pre Production is precisely the integration with Docupoint and ArtiosCAD.

It is appropriate to analyze the dynamics underlying the two macro categories of items that require budgeting. Within the category of simple articles we consider the American, die-cut boxes, the cases, that is, all the products composed of a raw material and a linear production process which for the estimate do not necessarily require an accurate CAD technical design, but rather with entering a little information such as the type of box, raw material, dimensions, treatments and quantities, it is already possible to obtain a quote. With Docupoint all this is now possible directly from a web format which can therefore be created with any PC, mobile or tablet device, inside or outside the company.

In the category of complex items we consider bottom and lid boxes, boxes with interior, lined boxes or displays, i.e. all those products composed of multiple raw materials and different production processes which necessarily require accurate CAD technical design for estimating. With ArtiosCAD Quotes & Orders we have completely automated this activity.”

How does ArtiosCAD Quotes & Orders integrate with your business management software?

“Trocart in this context was facilitated as we installed all the Packway management software in 2016 so the integration is native.

However, we know that the entire Packway Pre Production suite, including ArtiosCAD Quotes & Orders and Docupoint, can be installed and integrated with any management software through standard market protocols API-REST, JSON, XML and TXT.

All Packway Pre Production modules are very simple to use and have a low economic impact. In fact, they are offered with a monthly rental logic in relation to the number of users. They were developed to be integrated with the management software present in the company. The objective declared by B+B is to improve software automation without replacing what is already in use, but rather integrating the current infrastructure with industrial technologies that can become one with its systems”.