More than 100 participants discussed the EU’s view on the bio-economy, recent market developments in the European paper sack and sack kraft paper industry, different bio-barrier developments and how megatrends can be integrated in the packaging industry. During the EUROSAC Grand Prix Award ceremony, the industry’s latest innovations were honoured.

With a slight plus of 1.2% paper sack deliveries in 2018, the European paper sack industry recorded stable development. “Our industry is going through many trends and changes. We need to make sure that we can provide solutions that meet the needs of future market demands, especially in terms of offering various barrier functions by granting sustainability and recyclability at the same time,” stated EUROSAC president Olivier Tassel as he introduced the focus of this year’s congress topics.

“Bio-based materials are the future,” concluded Krassimira Kazashka, director from the International Confederation of Paper and Board Converters in Europe (CITPA) her presentation. “Concerning climate change, one of the EU citizens’ major concerns, paper packaging as a forest-based product has a great advantage: Forests are one of the keys to reducing emissions.” She gave a comprehensive overview of the priority areas, strategies and policies of the European Union concerning the bio-economy and how they can affect the paper packaging industry. Moreover, a keynote speech on megatrends provided inspiration on how to address global consumer trends in marketing and corporate business models to successfully shape the future of the packaging industry.

Regarding the industry’s circular approach, one of its set targets is to produce paper sacks that are made 100% from natural materials and fulfil the same functions as sacks with polyethylene (PE) barriers – protection of the product from migration, water (vapour), light, oxygen, aromas and grease, for example. Different companies introduced their innovative developments of highly functional and, at the same time, easy to recycle and biodegradable barrier materials and technologies to the audience.

Innovations were also the focus at this year’s EUROSAC Grand Prix Award. It honours the industry’s most remarkable inventions of the past year. A new element to the prestigious award is that EUROSAC introduced gold, silver and bronze categories and a public choice award for the first time. The jury was particularly impressed with the wide range of the innovations submitted, including services, raw materials and paper sack products. It chose the “secure-seal” carrier bag for food deliveries from Smith Anderson as the gold winner. “The best innovations are those that meet a particular need and offer value to the user,” said jury president Mark van der Merwe as he explained the jury’s decision. “The seal technology from Smith Anderson met the user’s need for security and reuse in a simple and innovative way without negatively impacting the aesthetic aspects of the packaging. It is also fully recyclable and biodegradable, fitting neatly with current end-of-life and sustainability requirements.”

The gold award was presented to Smith Anderson for its reusable, recyclable and biodegradable “secure-seal” paper carrier bag. It was developed for a big fast-food chain to combat undetected regular theft of small parts of food service delivery meals. A paper handle patch below the main handle structure was equipped with a double-sided adhesive tape, securing the bag’s sides together. A broken seal is easily visible to the customer on delivery – but doesn’t destroy the bag or handle area.

Segezha received the silver award for their brand-new dry mixes industrial paper sack made from its innovative SKE i4 paper. It meets the growing market demands for eco-friendly sacks with high performance qualities. The sack’s low weight and durability allows customers to reduce material and logistics costs as well as damages in the supply chain – and it saves CO2 emissions during transportation.

Segezha received the silver award for their brand-new dry mixes industrial paper sack made from its innovative SKE i4 paper. It meets the growing market demands for eco-friendly sacks with high performance qualities. The sack’s low weight and durability allows customers to reduce material and logistics costs as well as damages in the supply chain – and it saves CO2 emissions during transportation.

Double Grand Prix Award winner was dy-pack: The German-based company won the bronze and public choice award for Vardy. The highly efficient barrier coating on the inside of the sack’s outer layer provides state-of-the-art water vapour protection. Vardy is an environmentally friendly alternative to PE film and suitable for direct food contact. It allows easy recycling in the paper waste stream and is compostable according to DIN 13432.

Double Grand Prix Award winner was dy-pack: The German-based company won the bronze and public choice award for Vardy. The highly efficient barrier coating on the inside of the sack’s outer layer provides state-of-the-art water vapour protection. Vardy is an environmentally friendly alternative to PE film and suitable for direct food contact. It allows easy recycling in the paper waste stream and is compostable according to DIN 13432.

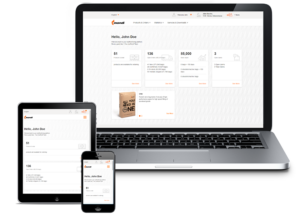

Moreover, the Grand Prix entrant Mondi presented a new platform for smooth business processes: myMondi is the only all-in-one digital customer platform for paper sacks worldwide. The platform offers numerous functions and information with few clicks such as stock reports, order history and status overview, invoices overview and filtering, certificates and detailed product specifications. It is simple to use and navigate, available 24/7 and gives customers full transparency about their products and orders, anytime and anywhere.

Moreover, the Grand Prix entrant Mondi presented a new platform for smooth business processes: myMondi is the only all-in-one digital customer platform for paper sacks worldwide. The platform offers numerous functions and information with few clicks such as stock reports, order history and status overview, invoices overview and filtering, certificates and detailed product specifications. It is simple to use and navigate, available 24/7 and gives customers full transparency about their products and orders, anytime and anywhere.