20 years of activity represent an important milestone in the life of systec brand, leader in design and construction of plate mounting systems for the flexible packaging, labels and corrugated cardboard industry, with over 1000 installations worldwide, celebrates this milestone with new initiatives in this special period

Digital tools are an important spring board in a changing world: SYSTEC has organized a webinar for the presentation of the new MIDI-iTABLE automatic plate mounting machine in collaboration with Printronics India, supplier of systems and equipment for printing and converting industry, which represents SYSTEC in the Indian sub-continent.

Digital tools are an important spring board in a changing world: SYSTEC has organized a webinar for the presentation of the new MIDI-iTABLE automatic plate mounting machine in collaboration with Printronics India, supplier of systems and equipment for printing and converting industry, which represents SYSTEC in the Indian sub-continent.

SYSTEC is a brand created by the Caliari family, which began the development of plate mounting machines in 2000, obtaining various successes and patents for advanced technological solutions over the years. SYSTEC machines are sold all over the world, also thanks to a global sales network that has more than 30 agents. Since 2015 SYSTEC brand has been acquired by the Swiss company STI Società Tartuca Industriale SA, consolidating and revolutionizing its technologies and developing new services and products for the world of printing and converting.

The range of products is completed with systems for plates disassembling, laser anilox cleaning systems and a warehouse for storing sleeves.

The heart of the SYSTEC solutions is represented by the ultra-high definition digital cameras, mounted on all the plate mounting machines sold on the market, starting from the basic model.

We know how plate mounting is a crucial step in the flexographic printing process and the quality of the print register is directly related to the quality of plate mounting.

We know how plate mounting is a crucial step in the flexographic printing process and the quality of the print register is directly related to the quality of plate mounting.

The correct plate mounting procedures recommended by technical associations such as FTA and ATIF consider a good mounting if the level of the print register is below 50 microns.

“Our mounting systems guarantee a register level below 7 microns, I would say well below the levels considered optimal”, comments Massimo Caliari, SYSTEC sales manager, before introducing the two great families of plates mounting machines: standard or automatic.

In the standard process the operator follows the reference points of the cameras, centering the mounting of the plate, while in the automatic system everything is managed autonomously by the smart digital system capable of recognizing the register marks and guaranteeing a perfect assembly, regardless of operator intervention.

“Our new automatic mounting system is a process based on neural link technology developed by our engineer Daisuke Matsushita thanks to which the software has the ability to automatically recognize the registration marks on both cameras, lock the image and provide immediate feedback to the iTable, the table on which the plates are held in place  by a vacuum system. iTable moves in 3 directions and is electronically controlled, in such a way to guarantee the correct position of the plate by following data from the cameras and the software. The iTable module can also be installed on our existing mounting systems, even if further software and digital camera updating is required”, says Caliari, underlining the advantages of an automatic procedure, which in the case of SYSTEC is capable of respect a tolerance of +/- 0.005mm, not to mention repeatability and a consequent rapid return on investment. During the webinar, several live demonstrations were carried out on flexo plate mounting technologies.

by a vacuum system. iTable moves in 3 directions and is electronically controlled, in such a way to guarantee the correct position of the plate by following data from the cameras and the software. The iTable module can also be installed on our existing mounting systems, even if further software and digital camera updating is required”, says Caliari, underlining the advantages of an automatic procedure, which in the case of SYSTEC is capable of respect a tolerance of +/- 0.005mm, not to mention repeatability and a consequent rapid return on investment. During the webinar, several live demonstrations were carried out on flexo plate mounting technologies.

SYSTEC has also introduced a customer assistance and support service by exploiting the augmented reality, both for the resolution of any technical problems but also for support in starting up the machine. Among the new projects that will be made available in the first quarter of 2021 is a new smart digital printer.

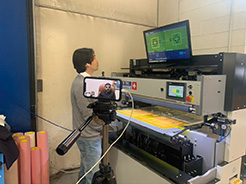

Smart digital printer for paper bags

With this new project, SYSTEC expands its range, by inserting a printing technology dedicated to printing of paper bags for indirect contact with food. Water based inks, piezo inkjet heads capable of printing at 45 linear meters per minute; the printer is also available in web-to-web version. “With this new project we want to offer a digital printing technology that can be useful for customizing paper bags with CMYK four-color printing, with a resolution of 1600×1600 dpi”, adds Massimo Caliari.

With this new project, SYSTEC expands its range, by inserting a printing technology dedicated to printing of paper bags for indirect contact with food. Water based inks, piezo inkjet heads capable of printing at 45 linear meters per minute; the printer is also available in web-to-web version. “With this new project we want to offer a digital printing technology that can be useful for customizing paper bags with CMYK four-color printing, with a resolution of 1600×1600 dpi”, adds Massimo Caliari.

This new product line responds to the need for diversification and the constant search for new products and new opportunities.

“We have found that many converters need to manage short or very short print runs, in particular for the customization of brands or ‘instant marketing’ advertising companies, for these activities the print runs cannot be managed economically even by a flexo printing process: here the difference is made by the flexibility of digital technology, that allows to obtain photographic prints and instantaneous management of the job through software, without the need for plates or pre-print activities. The world of digital printing is certainly very tied to our research and innovation features, the solution we are working on is truly ingenious and innovative and will be officially presented at next Drupa 2021”.