The appointments with the technical webinars of Uteco are renewed: last March Uteco presented, in partnership with Novamont, Sun Chemical and Ticinoplast, three new sustainable packaging solutions in the name of recyclability and circular economy

Uteco plant in Colognola ai Colli (Vr) hosted an interesting webinar which saw the four leading companies in their respective sectors join forces to create innovative and sustainable packaging solutions, presented by Elisabetta Fanesi, Application Development Manager of Novamont,; Anan Hiyasat, Area Sales Manager of Uteco for the Middle East and Africa; Claudio Martini, Sales Manager of Ticino Plast and Pierangelo Brambilla, Product Director, Global Laminating Adhesives & Cold-Seals, EMEA/LAR Functional Coatings of SunChemical

Uteco plant in Colognola ai Colli (Vr) hosted an interesting webinar which saw the four leading companies in their respective sectors join forces to create innovative and sustainable packaging solutions, presented by Elisabetta Fanesi, Application Development Manager of Novamont,; Anan Hiyasat, Area Sales Manager of Uteco for the Middle East and Africa; Claudio Martini, Sales Manager of Ticino Plast and Pierangelo Brambilla, Product Director, Global Laminating Adhesives & Cold-Seals, EMEA/LAR Functional Coatings of SunChemical

Sustainability in packaging

Sustainability is the main focus with which all industrial sectors have been called to confront for some years, but there are sectors, and packaging is one of them, which are particularly involved and exposed, where important changes are taking place, especially with regard to food packaging once their function of protecting and transporting food has been exhausted. The end of life is therefore a very popular topic within the packaging sector, and especially when dealing with materials such as plastic films, the complexities increase and more and more specific skills are required, from the early stages of planning and design of the packaging to production, with printing, converting and packing phases, obviously without neglecting the production of the material itself. A series of stages and production processes that involve various players in the chain, today increasingly at the forefront to give concrete and precise answers to final consumers. Collaboration between the leading players in the industry is one of the keys to the success of sustainable packaging.

The webinar entitled “Packaging and Sustainability: Innovative solutions for production chain of excellence” exclusively presented three sustainable packaging concepts, created using raw materials with a high renewable content and drastically reduced environmental footprint. Maintaining all the technological and communicational pluses, the partners joined forces creating the foundations for a more sustainable packaging future in the direction of an increasingly inclusive circular economy.

The webinar entitled “Packaging and Sustainability: Innovative solutions for production chain of excellence” exclusively presented three sustainable packaging concepts, created using raw materials with a high renewable content and drastically reduced environmental footprint. Maintaining all the technological and communicational pluses, the partners joined forces creating the foundations for a more sustainable packaging future in the direction of an increasingly inclusive circular economy.

The word to the protagonists: concrete commitments for circular economy-proof packaging!

“In the flexible packaging sector we believe that compostable materials can replace those packaging where multi-material and therefore not-recyclable solutions are still used today, or for all that series of packaging whose too small dimensions cannot be selected in the recycling plants currently available or in those situations where the packaging at the end of its life is contaminated by food, also avoiding that food waste can end up in the undifferentiated collection”, says Elisabetta Fanesi, presenting Novamont and the guidelines of sustainable packaging.

Uteco, which has always been attentive to aspects related to sustainability in the production of packaging, since it became part of the international industrial financial fund NB Renaissance has established new and important collaborations with other companies belonging to the same property, with which it has increased its study and development of innovative technological solutions aimed at an increasingly sustainable production. “In the Converdrome, the Uteco research center in Verona, all the technological innovations involving our business areas are born, flexo and gravure printing and laminating of flexible materials. We collaborate with industry partner suppliers but also with the most important international brands in the food & beverage, healthcare, packaging industry in general, with whom we test new technologies and new production procedures to offer the market 100% sustainable solutions thanks to the use of water-based or EB inks or the use of solventless adhesives for lamination”, says Anan Hiyasat, describing the main trends in the printing and converting market.

15,000 tons of material produced every year, for all packaging sectors, make Ticino Plast a reference player that for years has been pursuing the objectives of circular economy according to the classic three “R”: reuse, reduce and recycle. “Reusing in our sector is not an achievable goal, therefore at Ticino Plast we have concentrated on reducing and making recyclable the packaging produced with our films, obviously without compromising functionality”, says Claudio Martini. Reduction of thicknesses with more technical films and reduction of their density, but also the development, thanks to international partners, of bi-oriented polyethylene films, suitable for both printing and finishing processes with coating or vacuum processes that guarantee high gas barrier properties, to oxygen, aromas and water vapors are the result of Ticino Plast’s commitment to achieve an increasingly sustainable packaging industry. Thanks to the collaboration with Novamont, Ticino Plast has developed a range of compostable films for the food industry, which in June 2020 led to the launch on the market of nextFilm series by Ticino Plast, a product capable of transmitting the company’s values as far as it concerns circular economy and respect for the environment.

15,000 tons of material produced every year, for all packaging sectors, make Ticino Plast a reference player that for years has been pursuing the objectives of circular economy according to the classic three “R”: reuse, reduce and recycle. “Reusing in our sector is not an achievable goal, therefore at Ticino Plast we have concentrated on reducing and making recyclable the packaging produced with our films, obviously without compromising functionality”, says Claudio Martini. Reduction of thicknesses with more technical films and reduction of their density, but also the development, thanks to international partners, of bi-oriented polyethylene films, suitable for both printing and finishing processes with coating or vacuum processes that guarantee high gas barrier properties, to oxygen, aromas and water vapors are the result of Ticino Plast’s commitment to achieve an increasingly sustainable packaging industry. Thanks to the collaboration with Novamont, Ticino Plast has developed a range of compostable films for the food industry, which in June 2020 led to the launch on the market of nextFilm series by Ticino Plast, a product capable of transmitting the company’s values as far as it concerns circular economy and respect for the environment.

Sun Chemical with its wide range of products for printing and converting industry plays a role of primary importance in the production process of sustainable packaging, as Pierangelo Brambilla tells, “today in the development of sustainable projects we must take into consideration the life cycle of the products, so as to be sure that the innovations placed on the market are actually sustainable from an environmental point of view. Packaging costs must be in line with market needs without any kind of compromise regarding safety and food waste when we put new solutions on the market. Finally, we must keep in mind the strong commitment of policies and legislation to ensure compliance and anticipate changes in the choices of packaging solutions”.

The innovative solutions presented

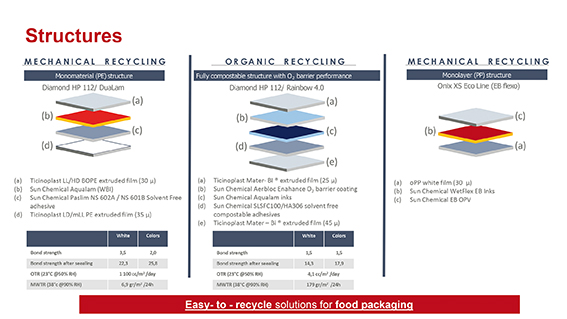

The first solution involves a compostable laminate for food packaging that can be organically recycled. Ticino Plast contributed with the transparent rigid film B100, obtained by extruding a new grade of Novamont Mater-Bi optimized for printing and lamination and capable of receiving further treatments such as lacquering or metallization and implementing the barrier effect, while Uteco used the machine Diamond flexo HP 112 for 10-color printing. The B100 film was treated with a two-component coating by Sun Chemical, which improves the oxygen permeability of the substrate, and was printed with Sun Chemical water-based inks. Ticino Plast’s B102 film was used as sealing layer, laminated with B100 to create a compostable laminate, usable for various applications in the food sector. Lamination was carried out on Uteco Rainbow 4.0 machine, a highly automated laminating machine designed for the specific needs of food packaging. For lamination it was used Sun Chemical’s compostable adhesive Solvent Free, with a low monomer content and a high renewable content.

The first solution involves a compostable laminate for food packaging that can be organically recycled. Ticino Plast contributed with the transparent rigid film B100, obtained by extruding a new grade of Novamont Mater-Bi optimized for printing and lamination and capable of receiving further treatments such as lacquering or metallization and implementing the barrier effect, while Uteco used the machine Diamond flexo HP 112 for 10-color printing. The B100 film was treated with a two-component coating by Sun Chemical, which improves the oxygen permeability of the substrate, and was printed with Sun Chemical water-based inks. Ticino Plast’s B102 film was used as sealing layer, laminated with B100 to create a compostable laminate, usable for various applications in the food sector. Lamination was carried out on Uteco Rainbow 4.0 machine, a highly automated laminating machine designed for the specific needs of food packaging. For lamination it was used Sun Chemical’s compostable adhesive Solvent Free, with a low monomer content and a high renewable content.

The second solution involves the creation of a 100% polyethylene mono-material laminate suitable for various applications in the food sector and suitable for mechanical recycling, to pursue the objectives of an increasingly circular economy. The film used is BOPE, a bi-oriented tenter-frame polyethylene film suitable for printing and coating in mono and multilayer applications.

In this case, Uteco used Diamond HP model 112, particularly versatile and precise, and the innovative technology of the DuaLam solventless laminating machine. For internal printing, Sun Chemical water-based inks of Aqualam series were selected, designed for high-speed printing of plastic films for lamination. Lamination between the two films was carried out using Uteco’s DuaLam lamination technology.

The third solution is aimed at lightening the weight of the packaging and declines the concept of the single layer with external printing, suitable for mechanical recycling. For this printing EB Flexo ink series was used in combination with EB Flexo overprint varnish suitable for sterilization. Electron Beam WetFlex inks contain no solvents and are therefore free from volatile organic compounds (VOCs). For printing Uteco used its special Onyx XS “EcoOne” machine equipped with EB3 technology, designed to use EB drying inks and guarantee high production efficiency, a speed of 300 m/min, reduced emissions and energy savings up to 30% compared to traditional solutions.

“We strongly believe in the possibility of providing sustainable packaging, and not only for the European market or in any case for those markets that are mature, but also and above all for emerging areas that are in great need of technology and know-how to produce their own green solutions”, concludes Anan Hiyasat.

Face to face with Eng. Alessandro Bicego, Chief of Innovation at Uteco

How did Uteco come out of these last two very special years?

How did Uteco come out of these last two very special years?

“The last two years have been extraordinary for us at Uteco, and thanks to the thrust of the new ownership we have launched an ambitious development plan with significant investments in all company areas for the next few years. We come from a challenging period on a global level, characterized by the pandemic, which has put a strain on all production sectors. In this scenario, Uteco has demonstrated solidity and resilience, with growing orders and a clear vision for the future.

Uteco wants to present itself on the market with a renewed plan of all its activities that combine an increasingly global perspective with a local presence, alongside its customers, to promptly assist them with products and solutions customized according to their needs. With a demonstrated ability to anticipate market needs and a clear vision of future trends, the company is ready to face new challenges, especially those imposed by climate and environmental crisis. It is in this context that in January we updated our image and brand, as a sign of further impetus towards the future with the desire to lead change”.

What are you developing to meet the demands of the sustainable packaging market?

“Together with our partners in the flexible packaging supply chain we are focusing on the development of completely recyclable materials, with single-material lamination structures (eg PE or PP), paper material (recyclable up to 7 times) and compostable and bio-based materials (eg. PEF or PLA). In addition, we are strengthening our technologies that enable the use of solvent-free inks, adhesives and coatings to eliminate emissions of volatile organic compounds and allow us to operate in safer production environments. These include water-based, Electron Beam and UV/UV Led products.

In this regard, Uteco has launched its “Academy”: training courses for internal staff and external stakeholders about various issues, including the sustainability of the flexible packaging supply chain”.

What innovations and recent developments are influencing the flexible packaging supply chain, involving brand owners, consumers and technology suppliers such as Uteco?

“We are witnessing profound changes in market trends and consumer needs, which influence the characteristics of the packaging and technologies used in the production chain. We believe that the growth of e-commerce sales channels and online shopping will increase the demand for flexible packaging, in search of increasingly innovative and efficient solutions. Personalization will be increasingly required, since packaging is now used as a means of interacting with customers, with specific messages that highlight the need to print highly variable information.

“We are witnessing profound changes in market trends and consumer needs, which influence the characteristics of the packaging and technologies used in the production chain. We believe that the growth of e-commerce sales channels and online shopping will increase the demand for flexible packaging, in search of increasingly innovative and efficient solutions. Personalization will be increasingly required, since packaging is now used as a means of interacting with customers, with specific messages that highlight the need to print highly variable information.

The growing demand for “on-the-go” and small/single-use products with an evident evolution of formats is meeting the demands of retailers, interested in packaging ready for retail to minimize space.

Hybrid digital printing solutions can support the demands of the packaging supply chain in terms of food and not-food safety, thanks to the traceability of the supply chain that can be guaranteed by the presence of highly variable identification codes such as the QR, for which digital printing is certainly the most suitable.

As far as energy saving is concerned, the increasingly efficient printing technologies from an energy point of view, allow to reduce the consumption of machines and the emissions of toxic substances in the air and in the workplace, finally, great attention also to safety and automation, where advanced systems for printing and converting processes are aimed at reducing material waste to a minimum, ensuring to the operator to work in total safety”.