Easyfair, the company that organizes Packaging Première dedicated one of its interesting webinars to the role of the label in the wine sector: in addition to performing its countless functions, today the label must also meet sustainability demands of consumers

The label in the world of wine must perform important tasks such as reporting information, describing and enhancing the contents of the bottle, capturing consumer’s attention, transmitting the link with the territory, communicating the historicity of a brand or the freshness of a brand, to convey the values of the manufacturer. But when the winery’s commitment goes in the direction of sustainability, the label must not only communicate an abstract idea of green to the consumer, but it must also transmit the values of a responsible production process, through the use of recycled materials, the selection of virtuous suppliers, the transformation of waste into a resource, all actions that jointly provide a precious and indispensable contribution to real protection of the environment.

The label in the world of wine must perform important tasks such as reporting information, describing and enhancing the contents of the bottle, capturing consumer’s attention, transmitting the link with the territory, communicating the historicity of a brand or the freshness of a brand, to convey the values of the manufacturer. But when the winery’s commitment goes in the direction of sustainability, the label must not only communicate an abstract idea of green to the consumer, but it must also transmit the values of a responsible production process, through the use of recycled materials, the selection of virtuous suppliers, the transformation of waste into a resource, all actions that jointly provide a precious and indispensable contribution to real protection of the environment.

Officina Grafica: atelier studio for production of packaging at the service of the wine sector

Officina Grafica was founded in 2006 by Vincenzo Maccarrone and Tommaso Pecchioli.

Officina Grafica was founded in 2006 by Vincenzo Maccarrone and Tommaso Pecchioli.

“Ours is an atelier studio where we dedicate ourselves to an excellent tailoring work whose sole purpose is to combine, in perfect harmony, history, philosophy and ethics of our customers. Attention to detail, cleanliness and elegance enhances the artisan spirit made of dedication and authenticity through which company, wines and territories are described”, say the two art directors.

Wineries live, by definition, a symbiotic relationship with nature and the environment that surrounds them. For this reason, the sensitivity towards environmental sustainability has always and increasingly manifested itself in all phases of the production chain. From the rationalization of natural resources to the more efficient use of all the elements that make up the packaging of their products (caps, capsules, bottles, cardboard boxes, wooden crates, etc.), each action aims to reduce at minimum environmental impact. The sensitivity on this topic is such as to lead wine producers from all over the world to dedicate a space on their site to make their commitment public and transparent. If the result may seem irrelevant if linked to the single bottle, the perspective changes drastically in the overall picture.

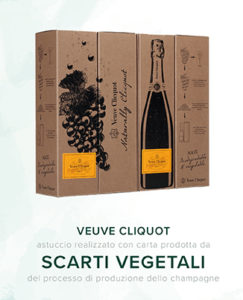

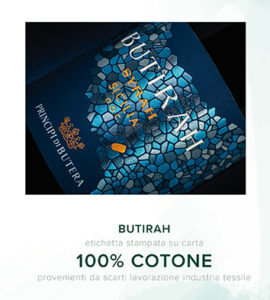

In an increasingly globalized society, increasingly frenetic and flooded with visual messages, it is essential that packaging conveys the desired message correctly and in an unambiguous way, whether it is a product intended for modern distribution, whether it is aimed at restaurants or wine shops. More and more often there are materials whose origin has the least possible impact on the environment. Substrates made with waste from wine  production and textile industry or with recycled materials. “In our case, we are witnesses and ambassadors of a radical change. We agencies have the task of conveying, through labels design, all the work and dedication that is found inside the bottle that is opened and shared. We are increasingly collaborating with companies that are aware not only of the importance of respecting the environment and the territory where they are rooted, but also of communicating it immediately and unequivocally. The label is the means through which the manufacturing company transmits its personality, its philosophy and its way of being. Media and technologies are the tools through which this message is created. The agency is the one who interprets, who encodes the story, a story that must deeply move”, conclude Vincenzo and Tommaso.

production and textile industry or with recycled materials. “In our case, we are witnesses and ambassadors of a radical change. We agencies have the task of conveying, through labels design, all the work and dedication that is found inside the bottle that is opened and shared. We are increasingly collaborating with companies that are aware not only of the importance of respecting the environment and the territory where they are rooted, but also of communicating it immediately and unequivocally. The label is the means through which the manufacturing company transmits its personality, its philosophy and its way of being. Media and technologies are the tools through which this message is created. The agency is the one who interprets, who encodes the story, a story that must deeply move”, conclude Vincenzo and Tommaso.

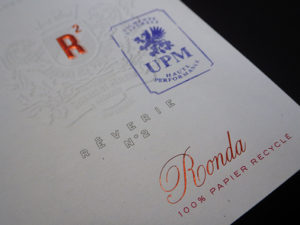

The approach to sustainability from the point of view of manufacturer of self-adhesive materials: UPM Raflatac is a virtuous example

Dario Santilli, Packaging Solution Manager Wine, Spirits & Food Italy of UPM Raflatac which produces materials for self-adhesive labels, within his company is a trait d’union between the world of designers and end customers for promotion and development of projects in which UPM is involved as a manufacturer of special papers.

Dario Santilli, Packaging Solution Manager Wine, Spirits & Food Italy of UPM Raflatac which produces materials for self-adhesive labels, within his company is a trait d’union between the world of designers and end customers for promotion and development of projects in which UPM is involved as a manufacturer of special papers.

UPM Raflatac has always pursued the goal of 360° sustainability with a very decisive approach towards the circular economy. “Just to give a sobering number, UPM plants about 100 trees per minute to help preserve resources and manage forests in a sustainable way”, says Santilli, data also confirmed by Forbes ranking which sees UPM in 24th place among the most sustainable companies in 2020.

According to McKinsey & Company, 79% of consumers say they value packaging sustainability when making a purchase decision. If we consider the Italian market, 61% of our compatriots are willing to change their purchasing habits to reduce the impact on the environment and 43% consider the environmental impact of packaging a very important aspect for the purchase of products. food. “These researches confirm that industry stakeholders are called to a greater commitment and at UPM Raflatac we offer solutions that are combined with the concept of circular economy and renewable sources, from the combination of which real sustainable packaging solutions arise”. UPM Raflatac has created the Label Life program in this regard to offer a life cycle assessment (LCA) service providing a holistic view of reducing the environmental impact of packaging, certifying the results of this assessment to end customers.

UPM Raflatac has also provided a plan, called RafCycleTM, to transform waste into a resource, proposing to end users a tool that offers new life to waste, that is the silicone paper that forms the basis of self-adhesive label, which is collected, recycled with own technologies present in the paper mill, giving life to new materials both for the self-adhesive industry and for paper or through the creation of materials for outdoor use in construction industry.

UPM Raflatac has also provided a plan, called RafCycleTM, to transform waste into a resource, proposing to end users a tool that offers new life to waste, that is the silicone paper that forms the basis of self-adhesive label, which is collected, recycled with own technologies present in the paper mill, giving life to new materials both for the self-adhesive industry and for paper or through the creation of materials for outdoor use in construction industry.

“A virtuous example is that of Cantina di Soave which in the last three years, since joining the project, has recycled 62 tons of silicone paper, avoiding its disposal in landfills, obtaining a saving that is equivalent to the energy needed to illuminate Eiffel tower for 15 months. The company has exploited this result in terms of communication, obtaining a great impact within the wine market, testifying how a serious project of circular economy and sustainability can also be exploited to bring added value to the product and therefore to the consumer. more inclined to accept a product with sustainable packaging”, concludes Dario Santilli.

Rotas Italia: well finished labels that produce oxygen

Special guest of the conference, an enlightened entrepreneur-inventor with a great humanistic vision, strongly linked to the territory where his company operates. We are talking about Francesco Celante, who has always been sensitive to social and environmental responsibilities (he has a degree in sociology), who today continues his commitment to the environment in the activity of printing labels with technologies he also invented, holds 7 patents, and uses innovative materials, unthinkable if we think of printing labels with the lava of Etna volcano.

Rotas has its production site in Treviso, right in the city in a highly urbanized area, where Celante decided to create a park, connected to his company through a wooden bridge, made using processing waste, which combines work and nature. “The environment is everyone’s property, we have it on loan and we have the obligation to keep it, while instead I have the impression that today the attractive mechanism of money and its accumulation has become the first goal of life. With the creation of this city park, we at Rotas want to give a strong signal, because industrial production and respect for the environment can and must coexist”, says Celante before moving on to tell the philosophy that drives his company in the production of labels. As you may have guessed, Rotas does not make simple products but there is a particular propensity towards that desire to amaze and give emotions, giving life and concreteness to the beautiful projects conceived by the designers. “An extraordinary product strongly linked

Rotas has its production site in Treviso, right in the city in a highly urbanized area, where Celante decided to create a park, connected to his company through a wooden bridge, made using processing waste, which combines work and nature. “The environment is everyone’s property, we have it on loan and we have the obligation to keep it, while instead I have the impression that today the attractive mechanism of money and its accumulation has become the first goal of life. With the creation of this city park, we at Rotas want to give a strong signal, because industrial production and respect for the environment can and must coexist”, says Celante before moving on to tell the philosophy that drives his company in the production of labels. As you may have guessed, Rotas does not make simple products but there is a particular propensity towards that desire to amaze and give emotions, giving life and concreteness to the beautiful projects conceived by the designers. “An extraordinary product strongly linked  to our territory like wine needs to be communicated and enhanced with something different that is not simply an image. We have a staff of engineers who study the designers’ projects to create labels that might seem impossible to make, such as the labels we printed for an Etna wine producer, using the lava of Etna volcano, or the one printed using the wine as ink. Do you think that the same bottle, with a label printed with conventional inks, is worth ten times less on the market”, says Celante, then presenting one after the other the innovations created by Rotas, such as the label containing seeds inside, which if planted in the ground, it gives life to a plant, or even the patented biolabel ecological label, produced with 80% stone, without the use of cellulose. “Sustainability is in our mind and it is a gift that Rotas has always given to nature, helping our customers to have sustainable labels”, concludes Celante, not before announcing the launch of a new research center in Treviso in which it will host the best brains that are able to bring new ideas to the fantastic world of self-adhesive labels.

to our territory like wine needs to be communicated and enhanced with something different that is not simply an image. We have a staff of engineers who study the designers’ projects to create labels that might seem impossible to make, such as the labels we printed for an Etna wine producer, using the lava of Etna volcano, or the one printed using the wine as ink. Do you think that the same bottle, with a label printed with conventional inks, is worth ten times less on the market”, says Celante, then presenting one after the other the innovations created by Rotas, such as the label containing seeds inside, which if planted in the ground, it gives life to a plant, or even the patented biolabel ecological label, produced with 80% stone, without the use of cellulose. “Sustainability is in our mind and it is a gift that Rotas has always given to nature, helping our customers to have sustainable labels”, concludes Celante, not before announcing the launch of a new research center in Treviso in which it will host the best brains that are able to bring new ideas to the fantastic world of self-adhesive labels.

Banfi, another virtuous example in the wine sector

The latest intervention featured Stefano Scardocchia, Sustainability Reporting Manager at Banfi, a wine producer with over 13 million bottles produced and sold all over the world, 400 employees and also a Relais that has also expanded the company activity to tourism sector, which has brought Banfi’s experience for environmental protection in the three areas in which it operates: agriculture, winery, logistics. Precisely this last aspect, that of product packaging and logistics, sees the use of approximately 83% of recycled cardboard.

Banfi also became the protagonist of a partnership with UPM Raflatac, precisely in the aforementioned RafCycle program, which led the company to reuse the waste resulting from the labeling process. In 5 years, 30 tons of glassine paper were delivered, which regenerated led to the production of 23 tons of cellulose pulp, with which 38 tons of paper were produced for printing about 187,500 magazines.

Hence, drawing up a sustainability report and communicating it to the stakeholders in the supply chain becomes an action of great value that also helps end consumers to understand and be able to verify if what the company is saying reflects reality. A reality that always and in any case starts in the few square centimeters of a label, capable of transferring emotions and values to the consumer!