Sun Chemical has collaborated with HP to launch sustainable flexible packaging produced with HP’s Indigo digital press and Sun Chemical’s new solventless lamination solution SunLam.

Due to its fast-curing, ultra-low monomer and solvent-free properties, SunLam can help brands improve their sustainability and expand the circular economy.

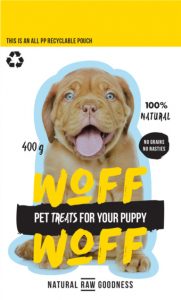

As part of the partnership, Sun Chemical and HP developed stand-up pouches printed on HP’s Indigo 25K digital press using monomaterial polyethylene (PE) and polypropylene (PP) substrates, and laminated with Sun Chemical’s SunLam solution. The all-PP pouch was certified by Germany’s Institute Cyclos-HTP after being successfully tested for a recyclability rate of 96%.

As part of the partnership, Sun Chemical and HP developed stand-up pouches printed on HP’s Indigo 25K digital press using monomaterial polyethylene (PE) and polypropylene (PP) substrates, and laminated with Sun Chemical’s SunLam solution. The all-PP pouch was certified by Germany’s Institute Cyclos-HTP after being successfully tested for a recyclability rate of 96%.

The PE and PP laminated structures were produced with HP Indigo using SunLam Adhesives ZA-1000+ZB-301 on standard mono materials with lamination on the Nordmeccanica Super Simplex E-800 solventless laminator.

Pierangelo Brambilla, Product Director, Global Laminating Adhesives & Cold-Seals Sun Chemical, explained: “The close collaboration between Sun Chemical and HP Indigo is helping develop faster routes to market for flexible packaging. By combining HP Indigo digital printing with the fast-curing capabilities of Sun Chemical’s ultra-low monomer adhesive, without compromising the overall quality of the package – a new solution is now available to enable printers and brands to meet the most stringent food safety regulations.”

He added: “These are just two great examples of how mono material PE and mono material PP were used to show how the proper selection of lamination adhesives and coatings demonstrate the fast-to-market value proposition of digitally printed pouches while providing more sustainable packaging and consumer choice.”

Itai Shifriss, HP Indigo WW Supplies Business Director, commented: “HP Indigo has been collaborating with Sun Chemical for many years to provide innovative solutions to HP Indigo customers. Today, demand for sustainable packaging solutions is driving converters to digital printing which can lower the impact of printing with on-demand production while eliminating plates and cylinders.

Itai Shifriss, HP Indigo WW Supplies Business Director, commented: “HP Indigo has been collaborating with Sun Chemical for many years to provide innovative solutions to HP Indigo customers. Today, demand for sustainable packaging solutions is driving converters to digital printing which can lower the impact of printing with on-demand production while eliminating plates and cylinders.