On 12 April, the training programme Serviforma – Die-cutting techniques from A to Z got off to a flying start. The course has been conceived and organised by Serviform, the established Caravaggio-based company and leader in technology and supply for die-cutter industries.

“We are particularly satisfied with the beginning of the 3rd edition of Serviforma, both for the number of participants – around thirty new enrolments – and for the fact that they come from all over Italy”, commented Paolo Fedrighi, the Materials Area Manager of Serviform. “This is confirmation that our initiative continues to find fertile ground and is seen and experienced as a tangible source of added value by sector operators.”

New for 2019

New for 2019

Thanks to the positive response to the structure of the individual modules, which was introduced in 2018, this year will see the training programme continue with a duration of 6 hours, from 9 a.m. to 3 p.m. The session on 12 April dedicated more room and time to one of the main subjects of the day: Engineering. In fact, at the end of the lesson, a live demonstration was organised for the Engview – Package and Designer Suite, the software dedicated to the creation of boxes and displays for points of sale for which Serviform is the exclusive representative in Italy. Matteo Cavenago, Product Manager for Engview, gave a live presentation of how to correctly set up the Single, how to calculate all the parts in order to avoid wasting cardboard (folding or corrugated) and how to optimise performance. An explanation was also provided on how to correctly set up the machine’s traction function, from controlling the sheet interlocked position to the total length of the machine format. At the same time, the participants had the privilege of being able to see a first-hand preview of the new feature in release 7 of Engview – Package and Designer Suite.

Designing a successful Single

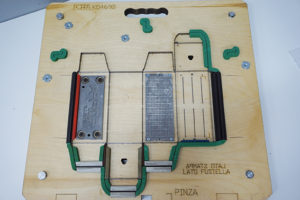

The problems associated with the design of the Single and the production of samples immediately captured the attention of the participants. Giovanni Goffi, a technical sales engineer, emphasised that the quality of the packing is closely tied to its purpose, which determines its form, and therefore its complexity in terms of material and finishing. Therefore, identifying the basic rules for the creation of a Single of significant impact that can be industrialised without losing sight of either productivity or cost is of fundamental importance for the entire process.

The problems associated with the design of the Single and the production of samples immediately captured the attention of the participants. Giovanni Goffi, a technical sales engineer, emphasised that the quality of the packing is closely tied to its purpose, which determines its form, and therefore its complexity in terms of material and finishing. Therefore, identifying the basic rules for the creation of a Single of significant impact that can be industrialised without losing sight of either productivity or cost is of fundamental importance for the entire process.

The world of stripping

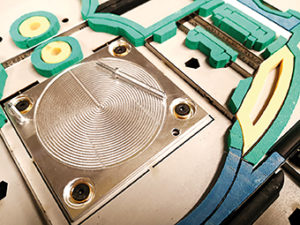

Stripping is one of the most delicate phases in the process of die-cutting. Knowing exactly what to clean and where; understanding when cleaning all the waste is an advantage and when instead it is advisable to use the waste as an aid in the process of extracting the sheet from the machine: thanks to a series of examples, Pablo Bogado, a great expert of the die-cutting industry, clearly illustrated and discussed the principles for achieving efficient extraction.

Stripping is one of the most delicate phases in the process of die-cutting. Knowing exactly what to clean and where; understanding when cleaning all the waste is an advantage and when instead it is advisable to use the waste as an aid in the process of extracting the sheet from the machine: thanks to a series of examples, Pablo Bogado, a great expert of the die-cutting industry, clearly illustrated and discussed the principles for achieving efficient extraction.

Lastly, the operating principles of the dynamic stripping process were explained, illustrating the cases in which it is advantageous to adopt this method and which drawbacks occur most frequently. The technique aroused significant interest and there were numerous questions from the operators who requested that the subject be studied in more depth in the future. To complete the picture and further the knowledge of the participants, a presentation was given of IntegrAStrip, a cutting-edge automatic machine from Proform for the production of stripping tools, such as dynamic forks, flat top blades and needle points.

The intensive day of training ended with application techniques for reliefs, which clients ever more frequently request in order to differentiate their products in an increasingly aggressive competitive scenario.

The intensive day of training ended with application techniques for reliefs, which clients ever more frequently request in order to differentiate their products in an increasingly aggressive competitive scenario.

The classroom was full of die makers, technical department staff, designers, quotation managers and sales managers who participated with great interest, sharing their own professional experiences, thus creating an exchange of information which was extremely open and useful for their reciprocal development. This aim was achieved, in accordance with the philosophy of the training programme, which places significant focus on the broadening of knowledge regarding die-cutting techniques for the entire production process. In this way the company is able to optimise production times and costs and significantly improve the quality of the finished product.

The next date has already been set. On 21 June in Caravaggio, the subjects will be cutting blades, rubbers, incisions embossing tools and maintenance of the die-cutter. Expectations are very high, but they will undoubtedly be exceeded by the enthusiasm and energy of Serviform in offering another day of training rich in content and useful practice for operators from die-cutter industries.