Present on the market for 23 years, Remac was born as a labor services company for companies in the sector, and then dedicated itself from 2002 to building of mixers for adhesives and finally from 2006 to building of some special components for laminators. In the following years, Remac becomes more structured and specialized in the building of compact laminating machines, arousing the interest of the major international brands that wanted to start collaborations on this type of machinery. In a short time the know-how in the hands of Remac arrives at such a level that Sergio Piga, its founder, decides to give life to a highly innovative and revolutionary project, called Leg0, with 3 lines of compact machines with a modular concept.

The idea is as simple as it is innovative and we are sure that it will be able to attract the interest of flexible packaging converters. Remac has decided to offer a range of modular concept laminators which, starting from an entry level machine, can be subsequently updated. But let’s go step by step. After years of collaboration in contact with national and international players in the sector thanks to which Sergio Piga, from Piacenza by birth and training, has acquired considerable skills in the field of technologies for laminating of flexible packaging, he decides in 2017 to continue his entrepreneurial path strengthening its brand and expanding the sales network.

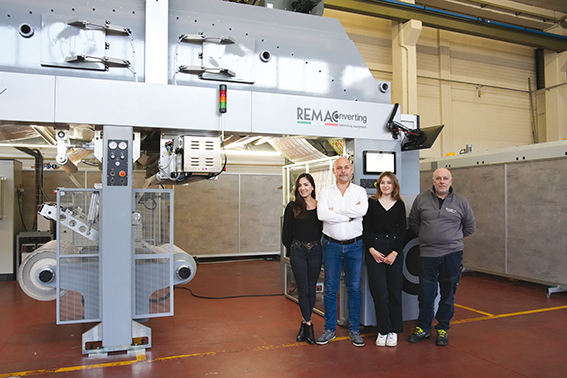

We are in Piacenza in an area where high-precision mechanics and companies serving the printing and converting sector for the packaging industry represent more than an opportunity for young technicians interested in having their say in the converting world, and Piga, who is young but has years of direct experience in the field behind him, dedicates himself with great passion to this new and solitary adventure. “I have always collaborated with leading Italian and foreign companies in the field of technologies for laminating of flexible packaging, building for them in my workshop in Piacenza the machines which were then marketed under their brands. Today there are no more agreements of any kind with any company and the time has come for us to present ourselves on the market with our logo by putting our face on a project to which I have dedicated myself”, says Sergio Piga, who today manages the company on the outskirts of Piacenza together with his wife and daughter and a group of around ten collaborators.

We are in Piacenza in an area where high-precision mechanics and companies serving the printing and converting sector for the packaging industry represent more than an opportunity for young technicians interested in having their say in the converting world, and Piga, who is young but has years of direct experience in the field behind him, dedicates himself with great passion to this new and solitary adventure. “I have always collaborated with leading Italian and foreign companies in the field of technologies for laminating of flexible packaging, building for them in my workshop in Piacenza the machines which were then marketed under their brands. Today there are no more agreements of any kind with any company and the time has come for us to present ourselves on the market with our logo by putting our face on a project to which I have dedicated myself”, says Sergio Piga, who today manages the company on the outskirts of Piacenza together with his wife and daughter and a group of around ten collaborators.

Where does the Leg0 project come from?

The Leg0 project stems from Sergio Piga’s precise desire not to enter markets already controlled by the big names in the sector, opting for the design of compact machines, characterized by innovative technological contents and an excellent quality-price ratio and above all by following an industrial model capable of being managed by a streamlined organization like Remac is today.

So what to do to stand out and carve out your own space in the converting market?

“I discarded the hypothesis of throwing myself into an already super crowded market where we would have had to compromise on price, with growing competition and I’m not talking about the well-known Italian and European players, but I’m also thinking about the machines from South-East Asia whose technological level is certainly not that of the past, we decided to propose a different project, offering the customer the possibility to purchase the entry-level machine and to subsequently update it, according to his eventual and future needs, up to being able to equip himself with the machine top of the range. Furthermore, this machine in its medium version is able to perform operations that other manufacturers guarantee with two machines, therefore with double energy consumption, double personnel, double required time”, says Piga.

The downtime required for the upgrade is just over a working week.

In doing so, Remac today offers itself on the market at a commercial level with a single catalog which, starting from the basic machine for certain applications, can be updated by inserting specific modules already foreseen, for a medium-level machine and finally for the top of the range, and each machine allows you to run different applications.

This range of laminators was obviously created to be able to produce single-material packaging, which is the focus on which all converters are engaged at the moment in order to be able to comply with the recyclability objectives of packaging imposed by the European Union, while guaranteeing the barrier characteristics, permeability, machinability, food preservation as if they were multiple materials. “Precisely because of these characteristics, coating requests are growing within the packaging sector and more and more converters are equipping themselves internally to perform these material treatment operations. With our machines we guarantee to process the two neutral materials on the same line, which are then transformed into the machine with the required characteristics, in a single step and on the same line”, adds Piga.

These are technologies intended for markets more sensitive to environmental issues and in Remac’s strategy, carried on step by step, great attention will certainly be immediately dedicated to Italy and Europe and then expansion is foreseen at a later stage to the United States, especially North America.

In September an open house with Sun Chemical

There are already 5 machines sold by Remac, in Italy to Ekaflex of Varese, Metalfilm of Lucca who are already using them in production, and the last one to an important Sicilian group which will be the protagonist before delivery, of an open house in the middle September which will take place at Remac headquarters in Piacenza in collaboration with Sun Chemical, and finally two machines destined for Algeria, one of which will be the top of the range.

For Sun Chemical, the event will have the aim of presenting its solutions of solvent inks, coatings and barrier adhesives for the production of mono material laminates (but not only). The solutions presented not only provide a valid proposal to market needs with a view to developing new sustainable packaging solutions but also, through the new machine developed by Remac and used during the open house, allow better control of production costs having the ability to apply coating and barrier adhesive in line.

“The offers we made to customers were all confirmed in a short time, precisely because our machine is not on the market and the event we will organize after summer will serve precisely to make the Italian and European market aware of all the main technical characteristics that our machines have compared to what is already on the market”, concludes Piga.