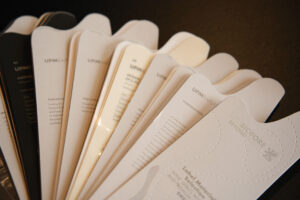

There are those who choose wine for its label and those who lie. This is precisely why a great wine deserves a label that is up to the brand, capable of telling its story, character and excellence. Today, in an increasingly competitive market, the label is not just an aesthetic detail, but a real communication and marketing tool. Design, materials, print quality and finishing make the difference in attracting consumers and enhancing the value of the product.

To explore the potential of digital label printing and finishing, Konica Minolta launched the “Print the difference” roadshow, an original and engaging format that brought the most advanced printing technologies directly to wineries, combining hands-on demonstrations and moments of discussion in an exclusive setting. An opportunity to touch the solutions and to taste excellent wines.

“With our roadshow we have concretely demonstrated how digital printing can offer new creative and productive possibilities, especially in such a demanding sector as wine”, said Marina Sedani, marketing manager of Konica Minolta Italia. “We chose wineries as the location precisely to emphasize the link between technological innovation and excellence of the final product”.

After a successful first stop in Valdobbiadene (TV), the event continued with a second stop at the evocative “Venti Venti” winery in Medolla (MO). We at Converter Flessibili – Paper – Cardboard took part in this event, delving into the role of digital printing and the innovations that are revolutionizing the label industry.

A complete and integrated digital printing process

Konica Minolta showed its AccurioLabel range, AccurioLabel 400 and AccurioLabel 230, embedded in a fully integrated production flow that covers all stages of label production. The process starts with digital printing, goes through embellishment thanks to the technology of the new MGI JETvarnish 3D Web 400, and ends with final finishing.

“Digital technologies have revolutionized the way labels are produced, offering greater flexibility, reduced waste and excellent quality”, explained Alessandro Viganò, product manager at Konica Minolta Italia. “Today we can offer our customers, together with our partners, end-to-end solutions to achieve great-looking labels with a streamlined and efficient process”.

This configuration was possible also with the collaboration, at this specific stage, of Prati, an Italian company based in Faenza (RA) and specializing in finishing/converting since 1973, with an established international presence thanks to its Dallas headquarters.

“Our partnership with Konica Minolta stems from the desire to offer a complete production process of the highest quality”, explained Chiara Prati, Prati’s Sales and Marketing director, presenting Digi Compact, a compact and highly customizable digital finishing solution designed for converters who focus on efficiency and high performance. The integration of these technologies allows the process to be completed with die-cutting, protection through the application of flexo protective coatings and embellishments, such as glossy, matte, gold and other exclusive laminations. “Finishing is what maximizes the value of the final product, making it unique and ready for the market”, she concluded.

The materials: the value of the substrate

To further enrich the project, UPM Raflatac, one of the world’s leading manufacturers of paper and film reels for label printing, also stepped in. The company with a wide range of innovative papers and products, showed how the choice of material can influence not only its aesthetic appearance, but also its durability and sustainability, an increasingly central issue in the industry.

“The future of labels also passes through the choice of more sustainable materials”, emphasized Ilaria Postuti, Sales Manager Italy at UPM Raflatac. “Our range of materials offers innovative and environmentally friendly solutions, without compromising quality and aesthetic performance”.

An event that makes the difference

If it is true that the label influences the choice of wine, it is equally true that behind every quality label there is an advanced technological process that enhances its value. The meeting at the “Venti Venti” winery offered a unique opportunity to see firsthand how digital technologies can meet the needs of this evolving market.

With the “Print the difference” roadshow, Konica Minolta confirms its role as an innovator in the digital printing industry, demonstrating how technology can be a key ally for companies and brands that want to stand out.

Because, in the end, the label is not just a detail, it is the first taste of what awaits us inside the bottle.