Durst’s “Pixel to Output” concept has been implemented very successfully at Edel Messereklame Digitaldruck GmbH. The company is now fully digital – from incoming orders to logistics – resulting in more flexibility and productivity while paving the way for greater diversification.

Frankfurt based Edel Messereklame is an established large format printer in Germany’s Rhine-Main region with a clear focus on business with exhibitions and events. Messe Frankfurt, for which Edel produces the complete wayfinding and signage systems for a number of trade fairs, is one prime customer. As a specialist for digital large format printing, the firm also caters for a huge range of other applications – including mega posters and banners on PVC, textiles or glass fiber as well as foil lettering.

It goes without saying that the business climate for Edel Messereklame, with its strong emphasis on exhibitions and events, has taken a dramatic turn for the worse as a result of the coronavirus crisis. “We launched into 2020 raring to go but then Covid-19 sent shock waves through all of our plans. We took advantage of the unexpected time on our hands to push ahead with digitization on all levels and move towards a more differentiated portfolio,” says Chief Operating Officer Christian Oehne, summing up the last few months.

Long-standing cooperation with Durst

Edel was founded around 60 years ago as a manufacturer of signs – at a time when advertising was still in its infancy. Today, the company employs about 30 people at its two sites.

Sales, graphic design and prepress are combined under one roof at the Messe Frankfurt Exhibition Center while all production activities take place on 1000 square meters of floor space in Bad Homburg. The first digital large format system was installed back in the year 2000 and the first Durst solution – a Rho 351 – in 2007. This was subsequently replaced in 2014 by a Rho 312 roll printer which is still in use today.

A concept fulfilled

“We’d already known for a while that our processes were in urgent need of optimization. However, in the hectic daily routine those good intentions were not followed through,” Oehne continues, stressing that the supply chain is where money is earned nowadays rather than with printing itself. Durst’s “Pixel to Output” concept represents a strategy for end-to-end digitalization involving all stakeholders – from customers to producers and suppliers. “We were convinced by the idea of a smart factory from the outset. It was LIFT, which is an ERP system developed together with a large format printer in the United Sates and specifically tailored to the needs of the LFP sector, that ultimately tipped the scales in our decision to realize this project with Durst.”

“We’d already known for a while that our processes were in urgent need of optimization. However, in the hectic daily routine those good intentions were not followed through,” Oehne continues, stressing that the supply chain is where money is earned nowadays rather than with printing itself. Durst’s “Pixel to Output” concept represents a strategy for end-to-end digitalization involving all stakeholders – from customers to producers and suppliers. “We were convinced by the idea of a smart factory from the outset. It was LIFT, which is an ERP system developed together with a large format printer in the United Sates and specifically tailored to the needs of the LFP sector, that ultimately tipped the scales in our decision to realize this project with Durst.”

P5 – a flexible, hybrid solution

The Durst investment package comprises various hardware and software solutions, for example the P5 350 printing system, which is suitable for printing on both roll media and board up to a width of 3.5 meters. “The hybrid solution gives us tremendous flexibility. It significantly expanded our roll printing capacity, meaning we can respond even faster in the run-up to exhibitions and trade shows. And the option of printing on board is something that sets us permanently apart from competitors,” Oehne claims. Edel also acquired two of the key software tools in the Durst Ecosystem along with the P5 series printer. Durst Workflow+ automates the prepress workflow by automating data preparation and managing the entire production process centrally on all integrated printing systems, whether from Durst and third-party. Durst Analytics, on the other hand, provides valuable analyses of productivity statistics and printer workload right down to single jobs. Problems are diagnosed at an early stage and solved as part of preventive maintenance – leading to a further improvement in production reliability.

The Durst investment package comprises various hardware and software solutions, for example the P5 350 printing system, which is suitable for printing on both roll media and board up to a width of 3.5 meters. “The hybrid solution gives us tremendous flexibility. It significantly expanded our roll printing capacity, meaning we can respond even faster in the run-up to exhibitions and trade shows. And the option of printing on board is something that sets us permanently apart from competitors,” Oehne claims. Edel also acquired two of the key software tools in the Durst Ecosystem along with the P5 series printer. Durst Workflow+ automates the prepress workflow by automating data preparation and managing the entire production process centrally on all integrated printing systems, whether from Durst and third-party. Durst Analytics, on the other hand, provides valuable analyses of productivity statistics and printer workload right down to single jobs. Problems are diagnosed at an early stage and solved as part of preventive maintenance – leading to a further improvement in production reliability.

LIFT uplifts the supply chain

“The Durst Software Ecosystem has helped us establish a digital, end-to-end workflow that speeds up production, frees up resources and ensures consistently high quality. LIFT is a cloud based ERP system that has uplifted our complete supply chain from the time the order is placed to delivery,” Oehne confirms. According to the COO, LIFT’s number one USP is aptly illustrated by an actual POS campaign that was mailed to 1200 addresses. Different designs and quantities had to be produced for every single address. “We saved the administrative and production-specific data in the system and LIFT took care of the rest – it was truly awesome!”

“The Durst Software Ecosystem has helped us establish a digital, end-to-end workflow that speeds up production, frees up resources and ensures consistently high quality. LIFT is a cloud based ERP system that has uplifted our complete supply chain from the time the order is placed to delivery,” Oehne confirms. According to the COO, LIFT’s number one USP is aptly illustrated by an actual POS campaign that was mailed to 1200 addresses. Different designs and quantities had to be produced for every single address. “We saved the administrative and production-specific data in the system and LIFT took care of the rest – it was truly awesome!”

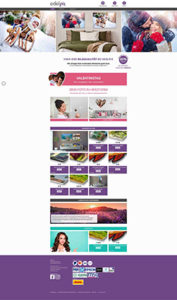

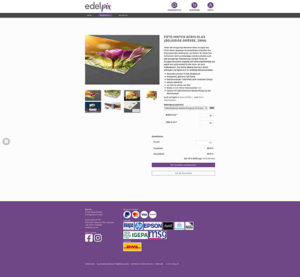

The investment package was simultaneously linked to the objective of reaching new customer groups in both the B2B and B2C segments. Durst’s Smart Shop is a simple, and above all scalable, entry-level solution for e-commerce with the accent on user friendliness. Professional web stores can be set up in no time thanks to its modular design while visitors can obtain fully personalized prints using the integrated Smart Editor. Christian Oehne: “We got off to a very successful start in online printing with edel-pix.de, the first web store that targets mainly private individuals. And a second store for B2B clients called edel-print.com is all set to go live in the near future.” He insists that without the Durst Smart Shop, it would have taken far longer to build a made-to-measure web store for personalized print products and affirms that the “Pixel to Output” concept has now been fully implemented.

The investment package was simultaneously linked to the objective of reaching new customer groups in both the B2B and B2C segments. Durst’s Smart Shop is a simple, and above all scalable, entry-level solution for e-commerce with the accent on user friendliness. Professional web stores can be set up in no time thanks to its modular design while visitors can obtain fully personalized prints using the integrated Smart Editor. Christian Oehne: “We got off to a very successful start in online printing with edel-pix.de, the first web store that targets mainly private individuals. And a second store for B2B clients called edel-print.com is all set to go live in the near future.” He insists that without the Durst Smart Shop, it would have taken far longer to build a made-to-measure web store for personalized print products and affirms that the “Pixel to Output” concept has now been fully implemented.