The world of customer service has taken a major breakthrough. The era of long waits and expensive trips is definitely giving way to rapid, specific and remote interventions, made possible by new technologies based on “virtual” presence and the Internet of Things. OMET has been following this path long since: diagnostics, increasingly precise, and production chain, now on the way of complete digitalization, are opening the door to an interactive, real-time customer service, with big time and money savings for customers.

The cornerstone of the OMET “Customer First” service is remote diagnostics. Appropriate software allows OMET technicians to remotely monitor any OMET line, wherever is it installed in the world, through a secure Internet connection. They can investigate any customer needs, interactively acting with local staff using chat, video or images. OMET customer service can remotely check real time parameters, trends and alerts, and perform remote tests, checkups as well as technical interventions.

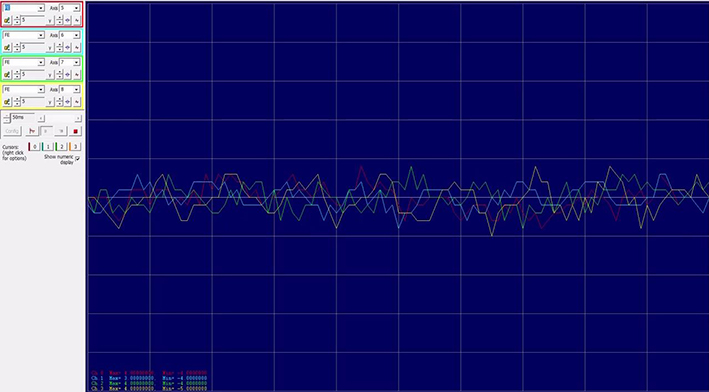

“A new remote connection system has been activated since 2012 and installed by default on every OMET machine since 2016 – explains Antonio Muraca, OMET Technical Assistance & Spare Parts Department -. On demand, it can be installed on previous lines. The software scans the machine, checking how devices and actuators are responding and producing diagrams and graphs that show the engines performances, allowing to identify immediately the cause of any alert. Trouble-shooting at a software level can be solved directly online, and mechanical interventions can be managed by on-site staff, virtually driven by OMET’s specialists that knows the machine in detail. If spare parts are needed, the involved parts can be excluded from processes to allow continuing the production”.

OMET customer service goes beyond on-call interventions. Data detected by the software allow the customer service keeping track of stops or malfunctions. The analysis of these trends over time make it possible to verify critical issues and take actions to solve problems and to increase the efficiency of the line with targeted interventions. Moreover, the analysis of deviations from the standard parameters allows to program maintenance, avoiding wear problems. This allows customers to have scheduled downtimes, with significant time savings and loss limitations.

“Statistics show that remote assistance allows to avoid up to 400 on-site interventions per year, solving customers’ needs in a few hours – says Muraca -. Recent web surveys report great satisfaction among customers for this kind of assistance, which allows to reduce significantly the loss of time and money associated with production downtimes”.

“Reliability is a value that has always made OMET standing out on the market: one of the cornerstones of our reputation – explains Marco Calcagni, OMET Sales & Marketing Director -. We are investing in the customer service because market satisfaction is our priority: we work constantly to make our machines and services bring efficiency, productivity and profit to the customers. Investment in 4.0 technologies is the key to the future, that will see also our commitment in augmented reality“.