The pandemic that is still ongoing has changed the habits of the end user, shifting by necessity, but also for convenience, many purchases from the shop windows and shelves of the physical store to those of virtual stores.

The protective capacity of the packaging and its ability to safely deliver intact products through the long and articulated chain of “multi-touch” delivery are the main factors that large managers in this industry evaluate when selecting ecommerce packaging materials.

The protective capacity of the packaging and its ability to safely deliver intact products through the long and articulated chain of “multi-touch” delivery are the main factors that large managers in this industry evaluate when selecting ecommerce packaging materials.

Other indicators and trends in the choice of e-commerce packaging, as reported by the main experts in the sector, are:

- Sustainability and environmental awareness;

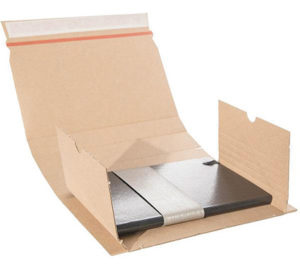

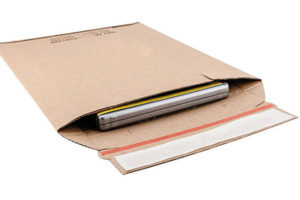

- Versatility of functional shipping packaging shapes: Boxes, folders;

- Selection of the most suitable packaging for product protection in order to reduce damage during transport and minimize the waste of carton material.

The focus on sustainable packaging has become a fundamental constant for consumers and brands themselves. The supply of more environmentally friendly packaging and the reduction of the amount of materials used are increasingly at the utmost place for e-commerce  companies. The packages used in e-commerce, being a secondary packaging, in addition to ensuring a high degree of protection of the asset within them and, considering the multi-level handling of the E-Commerce article, must also be extremely functional and as standardized as possible to ensure their “just-in-time” availability.

companies. The packages used in e-commerce, being a secondary packaging, in addition to ensuring a high degree of protection of the asset within them and, considering the multi-level handling of the E-Commerce article, must also be extremely functional and as standardized as possible to ensure their “just-in-time” availability.

The possibility of applying a simplified closure and easy opening to the packaging, guarantees a significant contribution of optimization and functionality of the entire packaging realization process and its subsequent use, in the transfer of the product to the final consumer.

More specifically, you can create a simplified closure with the application of one or more strips of glue covered with a silicone tape and the simplified opening from a strong tear-off tape arranged inside the packaging.

This type of application is not optimal in a bending machine because it would slow down its productivity, as the two strips are usually located transversely with respect to the running direction of the machine. Two passages of the same packaging would therefore be required, the first for the application of the tapes, the second for folding and gluing the packaging itself.

Or the folding fold should be supported, to perform the processing in a single step, by special and expensive devices such as those that turn the boxes at 90 ° to allow the second in-line processing.

Or the folding fold should be supported, to perform the processing in a single step, by special and expensive devices such as those that turn the boxes at 90 ° to allow the second in-line processing.

With the use of an ‘off-line’ machine, the folder-gluer machine maintains its flexibility and the process of applying the tapes takes place accurately and at a much higher speed than would be possible in the folder-gluer.

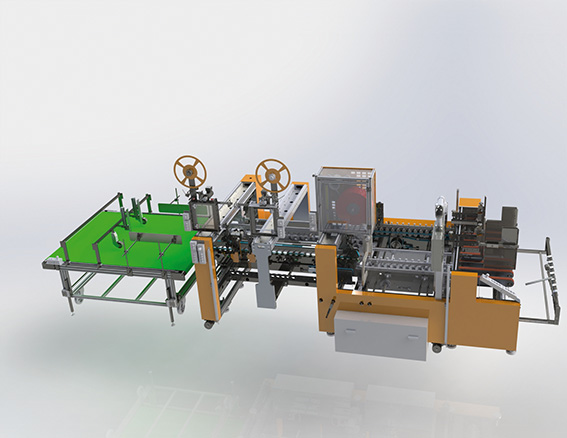

The most flexible and optimized solution is a “stand-alone” machine that works off-line able to handle any required die-cut geometry and that, as a dedicated line, applies both the glue covered by the silicone tape and the strong tearing tape.

Novesia presents E-Pack Pro 165

Ing. Michael Raab, CEO and owner of the company Novesia srl recently selected a line of application of adhesive, silicone tapes and tear-off tape for opening with performances never seen on the market. We are talking about the E-Pack Pro 165 machine, a modular machine that can be customized and expanded at any time for different needs.

Ing. Michael Raab, CEO and owner of the company Novesia srl recently selected a line of application of adhesive, silicone tapes and tear-off tape for opening with performances never seen on the market. We are talking about the E-Pack Pro 165 machine, a modular machine that can be customized and expanded at any time for different needs.

With a working width of 1650 mm, a special hotmelt electronic gluing device, two applicators for silicone tape and an applicator for tear-off tape, the E-Pack Pro standard version already meets all the needs of the E-Commerce Packaging industry. The management of tape applications on die-cut blanks even up to 25,000 pieces per hour exceeds any other system on the market.