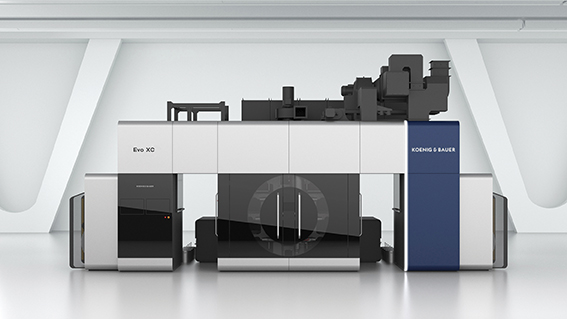

Presented last December with a streaming event, live from the company headquarters in Tavazzano (Lodi), the new Evo XC is a compact machine, with limited footprint, extremely ergonomic, within reach of the operator and also perfect for short runs.

During the presentation, a new print job was configured, the print and register control was set up, and a quick job change was performed. For the first job the plates were prepared by Inci-Flex with Crystal Led digital exposure technology: the job foresaw a set of 520mm size sleeves already mounted on the machine for preparing the print job to be carried out in three simple steps. In the first step, the Smart Sensing function during the approach of the anilox verifies whether the print format of the sleeves actually corresponds to that loaded in the machine’s memory. In the second step, a blue light indicates that the PrintTronic has started operation. It is an intelligent process of fully automatic adjustment of the printing pressure which requires very little time and low material consumption. Through PrintTronic it is possible to determine the optimal position and pressure of the printing cylinder, values determined by analyzing multiple points of contact between the sleeve and the drum. During the PrintTronic sequence from the machine data command and control desk, the operator can check at any time what is happening in each single printing unit, without the need to rely on video inspection systems external to the machine or dedicated notches or sleeves.

The Evo XC is provided in a configuration of up to 8 colors, and can print on a wide range of plastic, paper and laminated materials. Its main activity, the one for which it is certainly the most suitable choice for printing with profitability, are small and medium runs.

During the demo was realized a very particular job, with printing of 7 new generation water-based colors by Sun Chemical with a print development of 520mm on 12 micron PET material.

In the third and final step, which can begin when the PrintTronic light has turned green, the machine is put in register with the Smart-Register BST-eltromat system. A touch system allows the operator to enlarge the registration marks to overlap the virtual registration marks with the printed ones with a simple finger touch to calibrate the register and lock it in the most precise position. The operation is simple and in a very short time is performed for all colors to print. As the machine speed is increased, the register marks will remain perfectly stable. At this point the Evo XC is ready to print the first job at a speed of 350 meters per minute, not bad considering that water-based inks on flexible film have been used.

In the third and final step, which can begin when the PrintTronic light has turned green, the machine is put in register with the Smart-Register BST-eltromat system. A touch system allows the operator to enlarge the registration marks to overlap the virtual registration marks with the printed ones with a simple finger touch to calibrate the register and lock it in the most precise position. The operation is simple and in a very short time is performed for all colors to print. As the machine speed is increased, the register marks will remain perfectly stable. At this point the Evo XC is ready to print the first job at a speed of 350 meters per minute, not bad considering that water-based inks on flexible film have been used.

The demo was specifically designed with water-based inks precisely to highlight the DryTronic, the drying element developed by Koenig & Bauer Flexotecnica, which is mainly distinguished by two innovations. The first is the new concept of drying between colors with removable cassettes equipped with circular deep-drawn holes instead of nozzles to ensure maximum efficiency. The second is instead the “U” shape of the 3.6 meter long drying deck, positioned above the machine with removable panels on both sides of the material, which have the same circular deep-drawn holes of cassettes between the colors for absolutely perfect drying even at the highest production speeds.

The demo was specifically designed with water-based inks precisely to highlight the DryTronic, the drying element developed by Koenig & Bauer Flexotecnica, which is mainly distinguished by two innovations. The first is the new concept of drying between colors with removable cassettes equipped with circular deep-drawn holes instead of nozzles to ensure maximum efficiency. The second is instead the “U” shape of the 3.6 meter long drying deck, positioned above the machine with removable panels on both sides of the material, which have the same circular deep-drawn holes of cassettes between the colors for absolutely perfect drying even at the highest production speeds.

The second job was also printed in 7 colors with water-based inks, with 650 mm sleeves on the same material as the previous job. We remind you that the Evo XC can print a maximum width up to 1000mm and a maximum print development of 800mm. The only operation that the operator has to do during job change is to extract the sleeves and position those of the new job to be printed, checking again all the parameters as previously illustrated.

The demo machine was equipped with an automatic turret winder for automatic web change. According to the different needs of the customers, the machine is also available with single-axis or manual winders or unwinders.

The demo machine was equipped with an automatic turret winder for automatic web change. According to the different needs of the customers, the machine is also available with single-axis or manual winders or unwinders.

Also very interesting is the patented WashTronic system for inking and automatic washing, integrated in the machine, which works with the aid of a single pump: it achieves washing efficiency with minimum water or solvent consumption, while reducing air consumption and maintenance costs. Its location inside the monobloc printing unit allows the ink or cleaning product to reach the printing units in a very short time, reducing product consumption and allowing better accessibility for maintenance.

After the presentation of the machine, the experts from Koenig & Bauer Flexotecnica also spoke about other topics. First of all, the latest developments in the “Industry 4.0”, and in particular the software installed on all Koenig & Bauer machines that allows to collect and analyze all production data through VPN technology (Virtual Private Network) implementing the highest level of data security via remote access to protect the network from unauthorized access from the outside. With this broadband solution you can easily monitor all process data collected thanks to the numerous sensors installed in the machine and transform them into valuable information useful for production. Here are some examples: machine specific performance reports; consumption evaluation; advance troubleshooting and analysis with early identification of a possible potential source of error. All these reports are always at hand on mobile devices by installing Koenig & Bauer’s Progressive Web Application.

Later it was also told how Koenig & Bauer Flexotecnica manages service requests and which new measures have been implemented to respond more quickly and efficiently to customer needs.

The event ended with the presentation on hybrid machines in line with additional flexo or gravure downstream units for the application of special coatings and/or paints that can also be perfectly adapted for the new compact Evo XC machine.