Imprimatur Group distinguished itself at the latest edition of Best In Flexo 2024, winning first prize in the narrow web film category, supported by the prepress service Mavigrafica and with the decisive support of OMET, which in a very short time has become a strategic technological partner for this family business strongly marked by innovation, in continuous growth and increasingly a point of reference for the southern italian market

If only two years ago someone had told the Miulli family that one day they would take the stage at Best In Flexo to collect a first prize, they probably would not have been taken seriously this idea. Instead, that’s exactly what happened last November 14 in Milan, when at the awards ceremony of the competition that honors Italian flexo printing excellence, Imprimatur Group took first prize in the narrow web film category, with prepress support from Mavigrafica.

And up to here nothing strange, many companies were awarded in these years, but the peculiarity that distinguishes this beautiful and dynamic Apulian entrepreneurial company lies in the fact that the company, founded in 1976 in San Ferdinando in the province of Bat (Barletta-Andria-Trani) until two years ago was a traditional printing company born and raised on bread and flatbed printing for commercial and editorial printing like most traditional Italian printing companies.

Imprimatur Group’s values: people at the center

Characterized by a strong family involvement and with a female presence in a leadership role, as Anna Miulli, a sales woman and psychologist, in addition to being human resources manager also holds the position of CEO, the company has evolved by following market trends and with the simultaneous implementation of new production sectors that have earned Imprimatur Group the name of a true citadel of printing and increasingly a point of reference for the territory. The core values guiding the current management are flexibility and equal rights. The strong female footprint has allowed the establishment of a leadership that aims to optimize production processes by ensuring that flexibility that minimizes gender differences and aims to maximize the productivity of the single person. The numerous pink quotas give the company a “human” aspect, where the problem of a single person becomes the problem of all and where relationships assume a preponderant role, capable of positively influencing the state of well-being of everyone and, consequently, his or her productivity.

The gaze turned to flexible packaging

Today, after the latest investments, the company is divided into three macro areas of production, all coordinated by a highly specialized prepress department verticalized on market segments (food, publishing, packaging), which works in close contact with management and sales department and acts as a link with the printing area in a circular process where everything follows a predefined path and under control, until the delivery of the product to the customer.

“We predominantly serve a territorial market and are fortunate to work in a strategic and very lively economic environment, with various productive sectors ranging from agriculture to food, from tourism to culture. Multiple and multifaceted sectors that give us a lot to do. With the arrival of the new machine, we are growing further, facing with professionalism all those markets that require flexible products with a production increase already in the short term. Our instincts undoubtedly lead us to approach the world of plastic substrates in the future”, adds Anna Miulli.

First steps into the world of flexo

A first step led the Miulli family company to include the converting and finishing department and then in 2023 to decide to embark on an adventure in the world of flexographic printing by relying on OMET technologies, first with a second-hand FLEXY 330 that allowed the company to take its first steps into the label sector. “For those in the industry, OMET is definitely a point of reference, and our choice toward their technologies was dictated by our desire to rely on the best manufacturers on the market of flexographic printing presses to ensure the highest level of quality that the market can offer and to be certain that we have fully met the expectations of each customer”, Anna Miulli says.

But since appetite comes with eating, reel after reel, Imprimatur’s experience in the flexo sector has grown hand in hand with the needs of an ever-changing market, which has led the management of the Apulian company to decide to purchase a KFLEX, this time a new one, and to bring this authentic jewel of mechanical engineering for the first time to the service of customers in central and southern Italy.

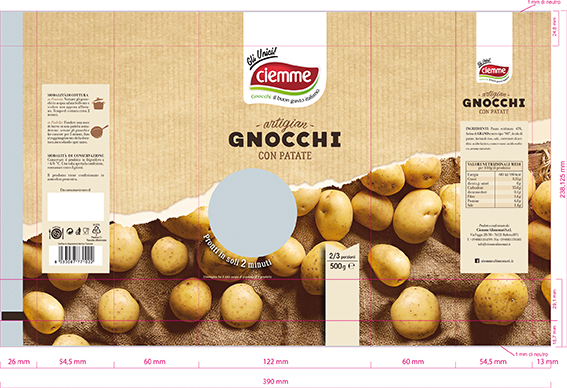

And it is precisely on this latest press that the winning work presented by Imprimatur was born: the company decided to participate for the first time in the competition organized and promoted by Atif, which rewards the quality of flexographic printing with a job that was appreciated by judges for the excellent balance and contrast, the appreciable cleanness in the application of the color, despite the complexity of the printed subject.

Face to face with Anna Miulli – Imprimatur Group

How was the winning entry chosen?

“The choice of the print project to be presented at Best in Flexo 2024 was dictated by purely technical aspects. The printer’s ‘clinical eye’ guided the selection phase among the various types of flexographic jobs we had in the pipeline. The study of light/darkness then decreed the final choice, the flexo printing project sent for competition and then emerged as the winner.

Can you describe it for us, with its particularities and eventual faced complexities?

“The project included several technical difficulties to be addressed such as: printing dot at 0.4 %, the elimination of the problem of the stamping effect and therefore the management of the window with the addition of white, the realistic reproduction of the product represented on the packaging and the ability to obtain the same color intensity using a four-color process instead of a pantone thanks to a high ruling cliché and anilox”.

Where did the desire to compare yourselves with more experienced and structured companies come from?

“Our choice was dictated by the desire to test ourselves, with an attitude that I would call ‘humble’. aimed at constructive comparison. We were born as offset printers and have a 10-year history behind us in this sector, but we have only been involved in flexographic printing for a few years. Participating in “Best in Flexo 2024” meant for us to access that platform of relationships and knowledge to be established and cultivated with industry veteran working partners.

What was your first thought and emotion when you were called to the stage in front of more than 500 people?

“The first thing we thought was, ‘together, we did it, we won!’ An indescribable emotion swept over us, a wave of joy and so, so much satisfaction! I think our level of emotion was felt by everyone. I only learned now that 500 people were present. There were so many of us, but at that moment there was only me, my brother and my dad”.

What will be your next plans for the future?

“Now we are projected to ‘Diamond Best in Flexo’, flying beyond national borders. We hope we can make it, at the very least we are fighting to give visibility to made in Italy jobs”.