By Marie-Soleil Boutet, Consulente e Area Sales Manager, IMPACK

As I visit packaging producers spread across 2 continents, I see over and over again that production managers are feeling the pressure to meet production demands while observing the strain manual packing puts on their finishing line staff. The problem is compounded by industry-wide labor shortages. Many packaging producers experience the highest turnover rates in the packing area of the folder-gluer line. How can you meet these challenges and seize opportunities for growth?

Ramping up the speed of your folder-gluer is one of the few ways to increase profits and stay competitive. The most significant folder-gluer bottleneck is the packing station. I have visited many companies that were not able to reach the maximum production potential of the folder-gluer, despite having three people hand packing. Hand packing is an extremely slow and painstaking process. The constant lifting and twisting movements cause serious repetitive strain injuries especially in the wrist and upper back. Your folder gluer is like a powerful and fast performance sports car, but with hand packing you aren’t able to reach its maximum speed.

In contrast, I have also observed optimized productions where automation has taken over the most strenuous tasks, transforming the workplace into a safer, more productive environment. By reducing personnel in these physically demanding roles, you are saving human resources for other value-added positions while increasing the speed of the folder-gluer.

You don’t necessarily need to automate every packing movement. In fact, if you produce short runs of a variety of complex box types a fully automated solution may not give you the flexibility and net speed you need.

When your packaging demands the irreplaceable precision of a human touch, the goal is to find a harmonious balance-automating the most grueling tasks while making others more ergonomic and sustainable. Other areas that benefit from various levels of automation are pre-feed, case management, case sealing and case palletizing functions.

Semi-automated Packing Solutions

Semi-automated packing stations reduce bending by incorporating shelves for samples and breakers at the packing station. Box turners are one of the best ways to reduce movements that can cause repetitive strain wrist injuries. Accumulation conveyors will control the density and flow of the shingle allowing a single worker to multi-task.

Automation can eliminate bottlenecks that limit folder-gluer speed.

Perhaps your mental calculator is already at work asking, “At what cost?”

The more critical question emerges: What is the cost of not investing in some automation? Consider the costs incurred from sick days and leaves of absence due to repetitive strain injuries in your facility over the past 5 years. Reflect on where your facility experienced the highest turnover. Calculate the actual cost of hiring and training new employees.

The real business case for ergonomics and automation in the packing area is in employee retention and increased capacity.

Calculating ROI for Automation Investments

Identify which manual tasks consume the most time and lead to repetitive strain injuries. By determining the time spent manually pre-feeding, packing, sealing, and palletizing you can ascertain the output and labor costs associated with these tasks. Return on investment can be quickly ascertained based on the increase in productivity, the life of the machine, and the cost of wages for the re-deployed workers.

After realizing initial ROI, packaging producers continue to experience profit gains due to increased capacity and the ability to fulfill increased demand.

We have developed ROI calculators to help packaging producers meet their profit objectives and have clients that have realized the following return on investment:

- ROI on a Simple Case Sealer: 3 to 9 months

- ROI on a Semi-Automated Solution: 1 year

- ROI on a Fully-Automated Packing Solution: 1 – 2 years

Increased capacity = increased revenue opportunity.

Determining Level of Automation

Automation should be tailored to your production needs. Fully automated solutions are built for speed and often see the most gain from long runs.

They will often be optimized to handle just a couple of box types in a limited size range. As already described, semi-automatic solutions offer more flexibility. Do you have two folder-gluers? With planning, you could dedicate one of your folder-gluers to long runs of a few box types to see maximum output and fully automate the pre-feed, packing, sealing, and palletizing processes. You can dedicate another folder-gluer to complex box types by integrating a semi-automatic packing solution.

Automatic Packing Solutions: High speed with minimal manual labor on a few box types.

Semi-automatic Packing Solution: Balance speed with flexibility for a variety of complex box types.

Seeing Results

For the past two decades, my colleagues at IMPACK have been studying the finishing line and engineering solutions to overcome inefficiencies and eliminate bottlenecks. Our passion is designing solutions that not only meet our customer’s demands for speed and productivity but also address the health and safety concerns causing labor shortages.

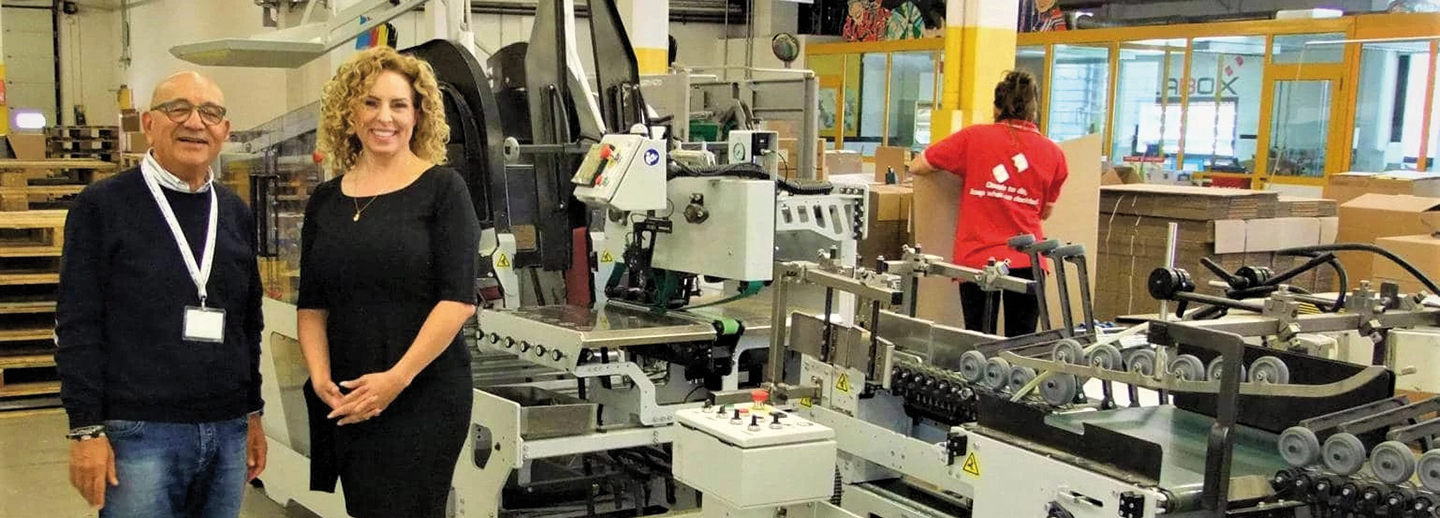

We talked with a few companies that have seen the importance of automation and technology that prioritizes both efficiency and the well-being of people. Automated solutions allowed Box Marche in Corinaldo, Italy to streamline their processes and maximize the capabilities of the existing workforce. This led to significant cost-efficiency gains.

Box Marche CEO Tonino Dominici explains, “Our employees are entitled to work in a stress-free environment, with as little physical strain as possible. To make that happen, we installed an Ergosa C and an automated Virtuo Packer from IMPACK of Canada on our two folder-gluer lines in 2008. Now that they’re in operation, no one at Box Marche has to lift heavy stacks of boxes. On top of that, we can now better exploit the productivity of our folder gluer lines. They can run at a faster rate and our team can produce more cartons in the same amount of time with less effort”.

Using a semi-automatic Ergosa solution, Alexir in the UK can now process a wide variety of box sizes and formats, reducing their packing staff by two and saving between £60,000 to £80,000 per year in wages.

Trevor Storr, Site Manager at Coveris Flexibles UK Ltd in Wisbech, UK explains that the semi-automatic Ergosa “offered a strategic solution to optimize our packing processes, allowing us to maintain efficiency and productivity even during fluctuations in personnel availability…maximizing the capabilities of our existing workforce”.

He explains that the Virtuo automatic packer reduced manual handling risks on thicker grade cartons, leading to improved KPIs in the finishing line and a faster flow of products through the site.

The experiences of Cartonage, Box Marche, Alexir and Coveris Flexibles underscores the transformative impact of ergonomics and automation in the finishing line.

These companies have experienced enhanced workplace environment and notable cost savings. By prioritizing both the well-being of people and operational efficiency, companies like these offer a compelling model for the future of packaging manufacturing.