By Stefan Badertscher – IMPACK

? You want to easily improve your folder-gluer’s department and at the lowest possible cost.

? You want a packing system that will save you money without limiting your production.

? You want greater output with fewer packing people.

? You want faster output with shorter setup times.

? You’re sick and tired of losing bigger contracts to competitors because of price.

? You want answers. And now.

I hear you.

My name is Stefan Badertscher and I am the Director of Sales and Marketing at IMPACK, a world-leading packaging equipment supplier, based in Canada, that designs, manufactures, and installs Folder-Gluer Packaging Equipment for carton board and corrugated box manufacturers. Over the last 8 years, I have personally visited over 400 production plants and saw, first hand, what the most and least successful packaging producers do in their day-to-day work.

My name is Stefan Badertscher and I am the Director of Sales and Marketing at IMPACK, a world-leading packaging equipment supplier, based in Canada, that designs, manufactures, and installs Folder-Gluer Packaging Equipment for carton board and corrugated box manufacturers. Over the last 8 years, I have personally visited over 400 production plants and saw, first hand, what the most and least successful packaging producers do in their day-to-day work.

These experiences have shown me how projects can fail in as little as the first few weeks because certain steps were not taken. More interestingly, those experiences have proved how simple investments can lead clients to realize monstrous success and dominate their market.

Today, I will be sharing with you the most effective ways to maximize your folder-gluer’s productivity and without holding anything back.

I will talk about what steps you should take, how to implement those steps, and in what order.

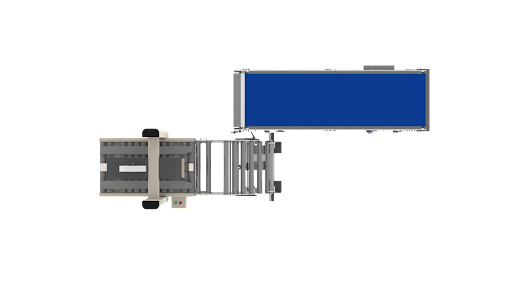

Tip #1: Add an Accumulation Conveyor after Your Folder-Gluer’s Compression Belt

Adding an accumulation conveyor will allow your packing personnel the ability to accumulate more boxes per meter of conveyor, hence the name “accumulation conveyor.”

This reduces the speed of your box shingle and allows more boxes within the same time frame.

This reduces the speed of your box shingle and allows more boxes within the same time frame.

As a result, your packing personnel will have more time, and peace of mind, which will lead to a naturally quicker packing process.

This is in contrast to having your personnel pack directly from the folder-gluer’s compression belt where there is no buffer if some boxes need to be checked/adjusted, or if some boxes slip out of their hands.

What I have seen very commonly among clients who do not have an accumulation conveyor is that their packing personnel will attempt to build their own buffer by emptying the compression belt as fast as they can.

This leads to a very non-ergonomic workstation.

The accumulation conveyor allows your packing personnel to have more boxes per meter of conveyor, thus giving them a more relaxed work experience and the ability to easily resolve any issues with the cartons if, and when, they happen.