The Heidelberg Boardmaster presented at drupa and now available at Wiesloch headquarters, had a great success thanks to its innovative technology and potential. A success that speaks Italian too, thanks to the partnership with BFT Group

Following the successful market launch of the Boardmaster, Heidelberg is planning to extend the range of applications for this new flexographic in-line web printing system to flexible paper packaging in the medium term. “The global increase in demand for sustainably produced, budget-friendly, and recyclable or compostable packaging makes flexible paper an attractive growth market for us”, says Christian Steinmassl, who is in charge of the Packaging segment at Heidelberg. “Our Boardmaster flexographic web printing system – which can process water-based inks, coatings, and barrier layers at production speeds of up to 600 meters per minute with an availability of up to 90% – is ideal for this market”, he adds.

Boardmaster in PMC at Heidelberg Wiesloch-Walldorf site

A complete Boardmaster will be available for customer demonstrations in the Print Media Center (PMC) at the Heidelberg Wiesloch-Walldorf site from drupa 2024 onward. The machine comes with several options for different customer requirements in order to be able to show interested parties as many automation and inspection functions as possible. The Boardmaster is available in a total of four printing widths ranging from 850 through to 1,650 mm.

When developing the system, the company focused on the key challenges and requirements of its customers – significant cost pressures, quality and operational reliability, sustainability, and high investment security.

“Systems are already operating in the USA, the order situation is very encouraging, and we have received inquiries from all over the world”, reveals Steinmassl.

Printers currently using large-format offset production for food and beverage packaging are also expressing an interest. The Boardmaster is designed for maximum overall equipment efficiency in non-stop operation with flying job changes. It achieves an availability of up to 90 percent and a printing speed of 600 meters per minute. This corresponds to double the productivity of previous, comparable systems. Maintenance costs are 50 percent lower than for systems that use other printing processes. A high degree of automation and simple operation support production with low staffing levels. This also counteracts the shortage of operating personnel. The AI-supported printing plate and sleeve scanner Intellimatch helps ensure print results meet high quality standards.

Partnership Heidelberg – BFT Group

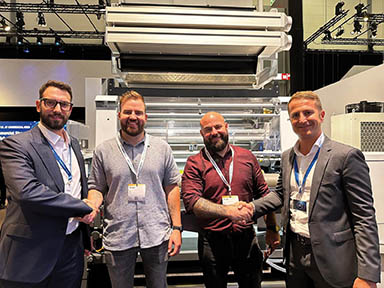

Boardmaster also speaks a little bit of Italian, thanks to the partnership between the German manufacturer and BFT Group, which developed and supplied the automatic inking and washing system, as well as the carbon fiber chambered doctor blade. BFT Group management were present at Heidelberg stand, next to the Boardmaster printing unit on display.

Face to face with Simone Bonaria and Alberto Ferrara, founders and owners of BFT Group

How did it go this experience with Heidelberg?

“Supporting technically Heidelberg for an ambitious project like that regarding the Boardmaster represented a highly stimulating experience for BFT. During drupa, we were able to directly observe the interest of visitors in this new concept of printing machines. The Boardmaster has attracted great attention thanks to its innovative technology and potential.

One of the aspects most appreciated by visitors was the speed and automation of the color change on the machine, a process entirely managed by our BFT Flexo inking and washing systems. This automation not only simplifies operations but also improves the efficiency and quality of the printing process. A key element of our inking technology are carbon fiber chambered doctor blades. These chambers are equipped with an automatic pressure management system, controlled via software by the machine itself. This system is designed to automatically compensate for blade wear, ensuring constant and optimal performance over time.

The experience of collaborating with Heidelberg on a project of this magnitude has allowed BFT to demonstrate its ability to innovate and its commitment to provide advanced technical solutions. The positive response received from Drupa visitors confirms that the path taken is the right one, and motivates us to continue developing technologies that can revolutionize the flexographic printing sector. This experience underlines the importance of working together with strategic partners to achieve ambitious objectives and to offer customers increasingly high-performance and efficient solutions”.

Let’s take a step back, how did your collaboration with the German manufacturer rise?

“Our collaboration with the renowned German manufacturer Heidelberg began while carrying out a retrofit on one of their machines installed in the United States at an important American group. Initially, the customer tested the BFT inking and washing system on a single printing unit. The positive results obtained led the customer to decide to retrofit not only the machine in question, but also several other machines present in the various factories. Impressed by the performance of our systems, the customer subsequently requested Heidelberg to equip the new machines with BFT systems. This marked the beginning of a collaboration that has led to significant developments up to the new Boardmaster and an ever-closer partnership with Heidelberg”.

Is it plausible to imagine your collaboration with Heidelberg also for other printing technologies or is the partnership focused only on the Boardmaster?

“The offset market certainly represents a very interesting opportunity, especially for the coating group. However, our priority objective is to complete the fine-tuning of the Boardmaster’s equipment. The introduction of our latest product, the automatic in-line cliché cleaning system, will play a crucial role for long runs. This system will guarantee optimal print quality even after hours of production, helping to keep the Boardmaster’s performance constantly high. With these developments, we aim to offer cutting-edge solutions that meet the needs of our customers and consolidate Boardmaster’s position as a leader in the automatic printing press industry”.