Hamilton Adhesive Labels Ltd., a leading converter of printed and plain labels for the food & drink, industrial, automotive, personal and household care markets with an annual turnover in excess of £12 million, has chosen Asahi AWP™ water-washable flexographic plates with CleanPrint. Hamilton operates from a 40,000 square foot manufacturing and warehousing facility centrally located in Bardon, Leicestershire, with a dedicated team of more than 65 people focused on product and service excellence.

Upon joining the company in 2016, Operations Director Paul Larkin, an industry veteran with more than 44 years of experience, was tasked with helping to make the business more sustainable and to identify low-cost changes that could have high productivity impact using his Measurement and Control philosophy, designed to deliver a predictive system that ensures “right first time” performance with world-class quality. He then formed a Formula One (F1) pit stop team tasked with optimizing productivity based on the new predictive system. He states, “Unless you can demonstrate a level of quality, the market is limited for any company.” Over his first year, Larkin examined every phase of the flexographic printing process, including flexographic plates, seeking ways he could improve it.

Larkin tested a wide variety of flexographic plates in his search for the perfect plate, testing them with thousands of meters of print. The ultimate choice was the Asahi AWP™ water-washable plates with Asahi CleanPrint, provided via the company’s repro house partner, Creation Reprographics.

“There is nothing out there like the Asahi AWP™ plates,” Larkin states. “They deliver a great tonal range and the dots are very stable.” He notes that ink on standard flexographic plates can be drawn to the shoulder of the dot, which can have a significant impact on running speed with frequent plate cleaning stops. “Using Asahi AWP™ plates with CleanPrint, it is completely different,” he explains. “The ink is somehow drawn to the tip of the dot, and the press is able to print continually without stopping for plate cleaning. It’s an incredibly consistent technology with world-class quality. It’s been a vital element of our quest to ‘get print right the first time!’”

Award-Winning Performance

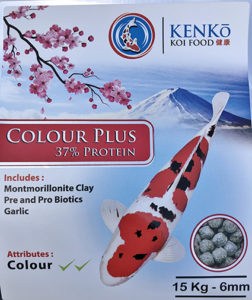

Not only has the company achieved a reduction in makeready time following its conversion to Asahi AWP™ plates with CleanPrint, but quality was also significantly improved as evidenced by awards its output has achieved. These include an EFIA Gold Award in the promotional category for a Crystal London label and the two Flexotech awards Best Print and Supreme (Best in Show) Awards. “This is the first time we have won this king of awards,” Larkin proudly reports. In presenting the award for Best Print, the judges stated, “Incredible vignettes to paper white, smallest dots ever seen in flexo, sharp text and high colour density. A superb promoter of flexo.” This praise was echoed in the judges’ statement with regard to the Supreme (Best in Show) Award: “We’ve been impressed at first glance; and the more we were checking the quality, the more we were convinced to be looking at a really ‘first in class’ piece of work.”

Benefits of Asahi CleanPrint

Asahi CleanPrint is designed to facilitate kiss touch printing pressure. Lighter printing pressure ensures constant repeatability of printing quality during the production run as well as longer plate life. This characteristic is achieved with unique Asahi-engineered photopolymer chemistry that reduces the surface energy of the printing plate and enables better ink transfer to the substrate during printing.

Asahi CleanPrint is designed to facilitate kiss touch printing pressure. Lighter printing pressure ensures constant repeatability of printing quality during the production run as well as longer plate life. This characteristic is achieved with unique Asahi-engineered photopolymer chemistry that reduces the surface energy of the printing plate and enables better ink transfer to the substrate during printing.

CleanPrint has the beneficial effect of reducing ink filling in the mid-tone area during the printing run, leading to fewer cleaning intervals and shorter press downtime for a highly sustainable flexographic printing process. Dr. Dieter Niederstadt, Asahi’s Technical Marketing Manager, notes, “Our customers, including Hamilton Adhesive Labels, are ecstatic about the quality of print they can deliver while also benefiting from reduced makeready time and improvement in OEE.”

Bright Future Ahead

Larkin sees a bright future for Hamilton Adhesive Labels and for the industry at large. “At Hamilton,” he says, “the combination of high quality printing components, including plates, inks and more, in combination with a sustainable company culture that operates from a Measure and Control philosophy with dedicated and talented employees on our F1 team, is driving the quality and price/performance of label manufacturing beyond that of any other printing technology available in the market. We are pleased to be working with Creation Reprographics and Asahi Photoproducts as critical partners that are helping us achieve our goals, win those prestigious awards, and look ahead to even more advances in the future.”

Larkin sees a bright future for Hamilton Adhesive Labels and for the industry at large. “At Hamilton,” he says, “the combination of high quality printing components, including plates, inks and more, in combination with a sustainable company culture that operates from a Measure and Control philosophy with dedicated and talented employees on our F1 team, is driving the quality and price/performance of label manufacturing beyond that of any other printing technology available in the market. We are pleased to be working with Creation Reprographics and Asahi Photoproducts as critical partners that are helping us achieve our goals, win those prestigious awards, and look ahead to even more advances in the future.”