A G1000 automatic ink quality control system was successfully installed, early July, on the new BOBST RS6003 rotogravure printing machine of the Edelpa production site in Santiago, Chile. Edelpa is committed in a process for total quality, from printing to the transport to the point of sale. About 90% of Edelpa products is represented by food consumer packaging and customers are the biggest food companies.

A G1000 automatic ink quality control system was successfully installed, early July, on the new BOBST RS6003 rotogravure printing machine of the Edelpa production site in Santiago, Chile. Edelpa is committed in a process for total quality, from printing to the transport to the point of sale. About 90% of Edelpa products is represented by food consumer packaging and customers are the biggest food companies.

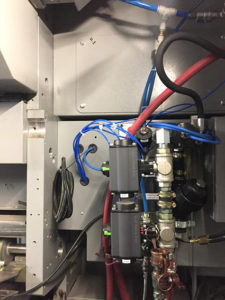

Thanks to the GAMA viscosity and temperature ink control systems, Edelpa has succeeded in implementing an automatic complete control system, improving quality consistency and reducing waste. This improvement will help Edelpa reduce production costs, and at the same time satisfy their demanding customers.