Respect for the environment and ability to seize the new challenges launched by e-commerce. From these two levers are born the solutions dedicated to wine and beverage. Resistant and attractive products, but above all 100% recyclable and biodegradable

Smurfit Kappa Italia launches a new series of proposals dedicated to the world of wine and beverages in general, united by two fundamental elements: use of a single material, corrugated cardboard and research of functional solutions for total protection of goods, which improve customer performance and transform a simple box into an impactful unboxing experience for the final consumer.

Smurfit Kappa Italia launches a new series of proposals dedicated to the world of wine and beverages in general, united by two fundamental elements: use of a single material, corrugated cardboard and research of functional solutions for total protection of goods, which improve customer performance and transform a simple box into an impactful unboxing experience for the final consumer.

Smurfit Kappa Italia’s offer for the wine sector has a long tradition and offers operators a wide range of packaging for every type of bottle, use and occasion: from die-cut boxes to displays, from box partitions to jars.

Thanks to the experience gained in this market, today the company focuses on e-commerce, a constantly expanding channel, also thanks to the pandemic that has changed the conditions of life and consumption.

According to McKinsey data, online sales of alcohol in Europe have increased by 34% with an increasing demand for sustainable, easy-to-open, high-protection and resistant packaging. Research conducted by Smurfit Kappa in European countries, including Italy, shows that 69% of the 8,000 respondents who buy wine online prefer paper-based packaging; 59% want easy-to-open packaging; 1 in 10 admits that they will think again before redoing an online order in case of damage to the goods.

Smurfit Kappa responds to this scenario with “e-Bottle”, a specific project for the wine sector. Expertise in cardboard processing, sophisticated software and tools together with the creative ability of designers have developed a series of solutions aimed at satisfying the needs of producers, retailers and logistics operators: first of all the protection of bottles subjected to travel and displacements and the resistance of their containers by favoring a 100% sustainable material such as cardboard. And then the ease and speed in preparing the packaging, the ability to adapt to different container formats, customization and, last but not least, the ability to create the wow effect during opening.

Smurfit Kappa responds to this scenario with “e-Bottle”, a specific project for the wine sector. Expertise in cardboard processing, sophisticated software and tools together with the creative ability of designers have developed a series of solutions aimed at satisfying the needs of producers, retailers and logistics operators: first of all the protection of bottles subjected to travel and displacements and the resistance of their containers by favoring a 100% sustainable material such as cardboard. And then the ease and speed in preparing the packaging, the ability to adapt to different container formats, customization and, last but not least, the ability to create the wow effect during opening.

Each bottle has its own solution

The “eBottle” project includes various packaging solutions available on the website, all tested according to the ISTA 3A standards defined by the International Safe Transit Association and designed using the eSmart process adopted by Smurfit Kappa to improve every aspect of packaging, from packing and filling to supply chain up to the final consumer experience.

The “eBottle” project includes various packaging solutions available on the website, all tested according to the ISTA 3A standards defined by the International Safe Transit Association and designed using the eSmart process adopted by Smurfit Kappa to improve every aspect of packaging, from packing and filling to supply chain up to the final consumer experience.

The project’s flagship product is the “Save the Bottle” patent pending system made with 72% recycled paper and 44% less material than the industry benchmark, while still guaranteeing maximum protection and resistance; it works for boxes of 3 bottles and multiples, it is supplied flat and already glued, there is no pre-assembly and with a single movement the operator forms the interior in less than 1 second. It gives maximum visibility to the product and the pack can be used as a display in your pantry or cellar thanks to the ability to view the product label without removing the bottle. A detail much appreciated by producers and consumers.

The BiPack solution was created to accommodate two bottles surrounded by high-impact graphics that reinforce the brand identity and offer an immersive experience in the world of the client company. The pyramid insert has been designed for the shipment of a single bottle, which ensures the necessary protection without hiding the product and its label; it adapts to any shape and guarantees a valuable brand experience in addition to the total recyclability of the packaging.

Alternatively, the cube solution offers a larger surface area suitable for accommodating additional communications.

Not only wine

Functionality and sustainability are the basis of TopClip, the patented plastic free alternative to the shrink film commonly used to hold together the multipacks of cans.

Entirely paper-based, does not require the addition of glue, can contain up to 40% recycled material, reduces CO2 emissions by 30%, is suitable for different configurations from 2 to 8 cans and, another very important feature for the safety of the customer, fully protects the top of the can.

TopClip solution is made in different Smurfit Kappa factories depending on the type of printing, to date it has been chosen by KHS, one of the world’s leading manufacturers of filling and packaging systems for the beverage and liquid food industry and has aroused a lot of interest from the producers of beer and soft drinks.

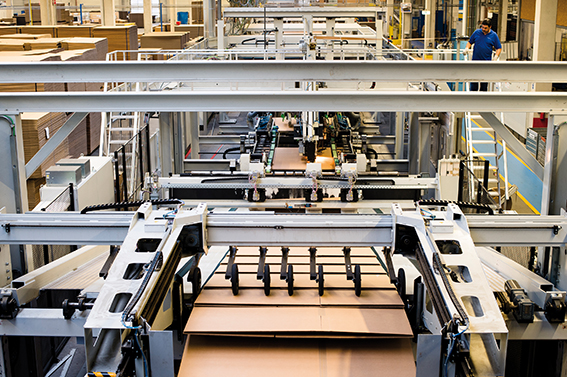

Thanks to Machine Systems, the division of Smurfit Kappa Italia dedicated to mechanization, the company is also able to provide mechanization solutions – one manual and one intermediate – ideal for market tests and promotions.

Face to face with Gianluca Castellini, CEO of Smurfit Kappa Italia

Can we say that from the Covid-19 pandemic arise also new opportunities for packaging suppliers?

“We are obviously talking about the biggest health crisis in Italy since the war, which is turning into a real national tragedy if we look at the overall numbers of deaths and sick people, not to mention the economic repercussions it is causing.

It is therefore difficult to see the “good” in what is happening. But if we try to escape from these speeches, it is certain that the general situation that has arisen, including the lockdown for so many months, has determined a radical change in the consumption and buying habits of Italians, which has also had a significant impact on the packaging market.

In fact, there has been a clear shift towards repeated and almost daily purchases in shops and supermarkets, the expenses for consumption at home have practically supplanted those in bars and restaurants, not to mention the explosion of online purchases of any kind. These situations have led to the demand for increasingly modern packaging solutions that are more suitable for new consumption”.

These specific products demonstrate how important it is to have direct knowledge of the end markets of your products. How are these solutions born?

“The key factor was and always is the relationship with customers and the building, over time, of real partnerships. We at Smurfit Kappa Italia always aim to present to our customers as someone they can rely on at 360° in defining their future vision of packaging of their products. Of course, there are also customers who ask us for a specific solution that they already have in mind and only expect us to develop and produce it for them. But in most cases, customers come to us with a need related to their business, a problem that plagues them with the packaging they are using, with the dream of radically changing their packaging to become more attractive, more sustainable or simply cheaper on the market. And we put all our creativity and experience at their service to develop a solution that is often unique, ad-hoc for each of them”.

With e-commerce, the role of packaging in the interaction between company-product and consumer becomes fundamental. What are the main requests of your customers to create that famous wow effect?

“A first fundamental request concerns the printing inside the box, which in e-commerce is obviously more important than the external one, which is almost always neutral. Once the box is opened, in fact, “a world opens up” and each manufacturer has the ability to customize the interior in the best way to create an experience for the consumer. They can be images, texts, information. Everything is needed so that the consumer, usually at home and often alone, can partially rediscover the shopping experience that in the past found when buying in stores. A second very important request concerns the mono-materiality of everything inside the box, which – with the exception of the purchased product – must be paper-based only. In the past there were plastic bags, polystyrene corners, paper clips or metal buttons. Today in Smurfit Kappa Italia the development of the box is instead conceived only with inserts in paper or corrugated cardboard, making the packaging sold online perfectly eco-sustainable, favoring the recycling in the paper container only”.

“A first fundamental request concerns the printing inside the box, which in e-commerce is obviously more important than the external one, which is almost always neutral. Once the box is opened, in fact, “a world opens up” and each manufacturer has the ability to customize the interior in the best way to create an experience for the consumer. They can be images, texts, information. Everything is needed so that the consumer, usually at home and often alone, can partially rediscover the shopping experience that in the past found when buying in stores. A second very important request concerns the mono-materiality of everything inside the box, which – with the exception of the purchased product – must be paper-based only. In the past there were plastic bags, polystyrene corners, paper clips or metal buttons. Today in Smurfit Kappa Italia the development of the box is instead conceived only with inserts in paper or corrugated cardboard, making the packaging sold online perfectly eco-sustainable, favoring the recycling in the paper container only”.

Sustainability does not only mean using a recyclable and sustainable material, but also designing a packaging right from the start, thinking about its end of life. What is your point of view on this?

“I think that in recent years the awareness of the effect that our behaviors as individuals and consumers have on the environment has become increasingly greater, hand in hand with the emergence in our society of opinion movements that ask companies, families and individuals to assume their responsibilities, also and above all towards future generations who will inherit the planet that we will leave them. In this discourse, the world of packaging is central, because everything or almost everything that is packaging then becomes waste in some way. And today we know that the material of which the waste is made has a disruptive effect on the environmental impact in the event that the disposal is not carried out in a controlled manner, therefore not differentiated and collected according to existing regulations.

So, if we think of a waste that is dispersed in a meadow or in the sea, it makes a big difference whether it is a cardboard box or a plastic packaging or a glass wrapper. Without qualms of looking partial, it is objective that in the first case the box biodegrades in a few days, while for plastic and glass it takes years if not decades. It is therefore up to us to choose, and today we have all the opportunities to do so consciously. We choose paper-based packaging. Even better if that of Smurfit Kappa Italia …”

Let’s talk about safety and resistance of the packaging: how is it guaranteed that a totally cardboard solution can be resistant to shocks and inconveniences of transport?

“Content protection has always been the primary requirement for any packaging solution, of course. But with e-commerce this need has become of utmost importance, because the product must pass a delivery that is made directly to one’s home and anything can happen. But not that, at opening, the product is damaged. This is why increasingly sophisticated and resistant packaging solutions have been developed in all areas. And also in everything that is paper-based, which with double or triple corrugated cardboard, is able to withstand any fall or damage, guaranteeing the manufacturer that even very expensive items, such as electronic ones or very fragile, such as bottles of wine, arrive intact to the consumer.

“Content protection has always been the primary requirement for any packaging solution, of course. But with e-commerce this need has become of utmost importance, because the product must pass a delivery that is made directly to one’s home and anything can happen. But not that, at opening, the product is damaged. This is why increasingly sophisticated and resistant packaging solutions have been developed in all areas. And also in everything that is paper-based, which with double or triple corrugated cardboard, is able to withstand any fall or damage, guaranteeing the manufacturer that even very expensive items, such as electronic ones or very fragile, such as bottles of wine, arrive intact to the consumer.

To this end, a series of internationally valid tests and certifications has been developed (such as those required by Amazon for purchases made through their portal) that packaging manufacturers like us at Smurfit Kappa Italia must pass in order to be accredited to supply packaging solutions for e-commerce.

An additional challenge that our designers have to overcome and that makes us proud when producers call us to thank us for the excellent solutions developed”.

Finally, a question that might have been obvious if asked to you, but let’s do it anyway. How do you live the eternal paper vs plastic diatribe, both from a professional and personal point of view?

“On a general level, I start from the consideration that in the last 100 years plastic has played a fundamental role in the development of the economy and the personal life of all of us. Our world and our life would not be the same. And even today plastic is irreplaceable for a series of processes and products, especially of a durable type, and it will certainly be so in the future as well. It is enough to look around us, at our home, in our office or in our factories, to realize what and how much plastic represents and will continue to represent for a long time to come.

However, the reasoning is different if we think of many products – especially single-use – which today are made of plastic but could be made with other materials. Being single-use, these are products that will quickly turn into waste and here we return to the sore point. If disposed of in an uncontrolled way, this plastic waste poses a real threat to the environment in which we live. Simply replacing them with paper-based products could radically solve or at least minimize the problem.

Speaking of packaging, we simply think of the myriads of plastic trays that we find in the fruit and vegetable departments of supermarkets, or the polystyrene trays used in gourmet foods departments.

Billions and billions of plastic trays and trays that could be immediately replaced by similar paper-based containers.

At Smurfit Kappa Italia we have created a special line in paper and cardboard called “Safe & Green” which is perfectly suited to all these needs. We already see them appear, albeit slowly, in many distribution chains, but we are only at the beginning.

However, I want to make a prediction: in 5 years, we will only find paper-based packaging in all our supermarkets. The new generations ask us, the environment in which we live asks us”.