FUJIFILM Integrated Inkjet Solutions is the team within the FUJIFILM Inkjet Business Division that designs and manufactures inkjet products for integration into other machines and production processes, and as part of custom printers.

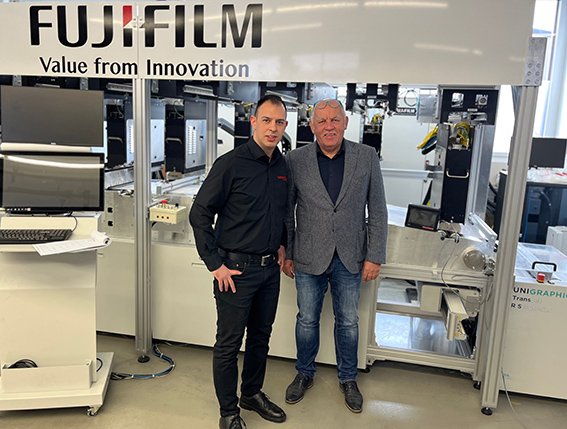

Leading each project is a dedicated and knowledgeable Fujifilm team able to leverage the resources and capabilities of its global technologies. According to Joseph Schweiger, Managing Director of FUJIFILM Unigraphica AG, Fujifilm’s integration team in Liechtenstein, “Our approach is to assign a dedicated team to each project so that we can deliver the best possible solution for each individual situation. We ensure smooth implementation, and across multi-sites if required. Whatever the configuration, proof-of-concept, testing, and validation stages are built into the process to ensure streamlined implementation.”

Fujifilm uses high inkjet print resolutions and small drop sizes such as 1200 x 1200 dpi with 2 – 13 picolitres of ink and printed only 0.8mm from the material being printed. “Such precision warrants high precision surface treatment, which is in large part why Fujifilm chose Vetaphone for its corona technology,” added Schweiger.

The Vetaphone corona technology installed at the Ruggell facility in Liechtenstein is one of the Danish manufacturer’s new VE1A-M 620 stations with four ceramic electrodes and a 2kW iCorona™ generator. It is fitted to a FUJIFILM TransJet RS 300-520 model in Fujifilm’s showroom and demo centre.

“We are very pleased with the performance of our Vetaphone corona technology,” he said, adding, “and our well-established working relationship with the company’s Area Sales Manager, Ahmed Türkmen, makes working with Vetaphone a smooth and enjoyable experience.” he concluded.