The months of March and April were full of commitments for the entire HP team which, on Dscoop Edge in Indianapolis, during the pre-drupa conference in Dusseldorf and finally in the three Italian events of the “Pre drupa Road Show” tour, presented all the news related to Indigo and PageWide. Three distinct moments, in different places, all characterized by a single common denominator: technology, innovation and a look to the future

In view of participation in next drupa, HP has warmed up its engines, trying to satisfy its customers curiosity and desire for innovation with a series of events during which the latest innovations of the American multinational were presented, sharing its strategic vision on the main reference markets: commercial, labels, flexible packaging and corrugated cardboard.

Regarding the Dscoop Edge event in Indianapolis, we invite you to read the article published in Converter & Cartotecnica May/June by our colleague Giada Chilà who took part in this prestigious event.

Campari Museum, where entrepreneurship embraces art, design and taste, an ideal place to reveal HP’s latest technological innovations

Glamorous locations also for the three events of the “HP Industrial Road to drupa 2024” which, after starting on 9 April at the Ferrari Museum in Maranello (Mo), continued on 10 April at the historic residence Borgo Tragliata (Rome) to end on 11 April at Campari Museum in Sesto San Giovanni (Milan), where until a few years ago there was the production site for the famous aperitif well-known all over the world and where Campari’s headquarters are now located, with the annex Museum, restaurant and a splendid garden. A place that certainly recalls the concepts of innovation, history and creativity that go well together with HP’s vision, together with the key pillars of the company DNA: quality, versatility, productivity, sustainability and attention to costs.

“Our strategy today is to serve the printing market in all its segments with a series of specially developed technological solutions. HP has invested and will continue to invest huge resources to always improve its machines from entry level to large volume technologies, focusing on automation and integrating Artificial Intelligence both in proprietary software but also in printing machines to make the operators’ work increasingly easier and simple”, said Markus Weiss, General Manager EMEA Go To Market HP Industrial.

What trends are driving the development of the sector?

Martina Corradi, Marketing Manager Italy & Iberia HP Industrial and Alessandro Bestetti, District Manager General Commercial Printing HP Industrial welcomed people present, an audience of selected HP customers through a journey that recalled the history of HP in the industrial printing sector, the milestones, the innovations introduced at past editions of drupa and a look at next fair to be held starting May 28th in Dusseldorf.

“I cambiamenti che la società sta vivendo, dall’esplosione dell’E-Commerce a nuovi modi di gestire il lavoro, negli ultimi anni hanno portato la nostra industria a dover rispondere al mercato con sempre più agilità. Tirature sempre più brevi, cambi di commessa frequenti, personalizzazione dei lavori sono richieste all’ordine del giorno per gli stampatori, che però faticano sempre di più a reperire manodopera specializzata, problema questo che sta portando le aziende a ricercare automazione e integrazione dei processi”, racconta Martina Corradi, sottolineando infine “come ci sia una grande fluidità di movimento fra i diversi comparti, questo anche grazie a tecnologie produttive che permettono con la stessa macchina di poter affrontare differenti mercati, e quindi si assiste di frequente a stampatori commerciali che si affacciano alla cartotecnica o a produttori di imballaggi flessibili che cercano sbocchi nelle etichette e viceversa. Aziende sane che stanno cercando di espandersi per crescere, dovendo tenere presente l’aspetto della sostenibilità. Tutte queste caratteristiche evidenziano la necessità di una grande agilità sul mercato e la strategia di HP parte proprio da queste ultime analisi. Le novità che verranno presentate da HP in drupa sono state concepite per tutti i nostri settori di riferimento: stampa commerciale, etichette, imballaggio flessibile, cartotecnica e cartone ondulato”, ha concluso Martina Corradi.

“The changes that society is experiencing, from the explosion of e-commerce to new ways of managing work, in recent years have led our industry to respond to the market with ever greater agility. Increasingly shorter runs, frequent job changes, job customization are commonplace for printers, who however are finding it increasingly difficult to find specialized operators, a problem which is leading companies to seek automation and process integration”, says Martina Corradi, finally underlining “how there is a great fluidity between the different sectors, this also thanks to production technologies that allow the same machine to be able to address different markets, and therefore we frequently see commercial printers that look towards cardboard converting or flexible packaging producers looking for outlets in labels and vice versa. Healthy companies that are looking to expand to grow, keeping in mind sustainability. All these characteristics highlight the need for great agility on the market and HP’s strategy starts precisely from these latest analyses. The innovations that will be presented by HP at drupa have been designed for all our reference sectors: commercial printing, labels, flexible packaging, cardboard converting and corrugated cardboard”, concluded Martina Corradi.

As recalled by Alessandro Bestetti, HP’s printing business in the Industrial division, which includes printing machines, is worth around 2 billion dollars a year, with installations in 82 countries, 45% in the American region, 40% in EMEA and Africa region and the remaining 15% in the Asia & Pacific region, for a market share of Indigo machines of 56%, 65% of which concerns label and packaging technologies, while PageWide, inkjet roll presses, it is worth 15% of the market.

“I would like to point out how HP, being the owner of all software and hardware technologies, guarantees its customers the protection and valorization of their investment, allowing them to benefit from all the updates released, without the obligation to change the printing machines, and this is certainly a great advantage for the customer and also responds to the needs of sustainability and cost reduction”, adds Bestetti.

HP’s proposals for labels and flexible packaging sector

Fiorenzo Dosio, Account Manager Labels & Packaging HP Industrial, presented the latest addition to the label sector, already seen at the last edition of Labelexpo Europe 2023, the HP Indigo V12, the first to be equipped with the new LEPx printing technology, here at Campari Museum in a complete configuration dedicated to high productivity, with the automatic reel cutter at entry, and the non-stop winder at the end. It is a machine that is positioned in the high end of the market and in competition with traditional label printing technologies, and thanks to the innovations, HP believes that the machine will be economically competitive up to, and probably even beyond, a print run of 5 thousand meters.

Inkjet printing technology normally involves a plate, 7 inkers, a blanket and the material to be printed. With each turn of the plate, one color is printed and in case of the label & packaging market, one-shot inking is used, meaning all the colors are collected in the blanket and transferred to the material at the same time, with advantage for speed. With LEPx printing technology there are 6 printing units, each equipped with a double inker that allows the simultaneous printing of 6 colors at a time. When printing up to 6 colours, the blanket makes a single revolution at 120 meters per minute, if further colors were needed, and 12 colors can be reached, the blanket would make two rotations for a printing speed of 60 meters per minute, an excellent result for digital label printing.

Another important innovation of this technology concerns the print head which is no longer laser, but LED, and this offers two advantages: the size is much smaller and offers double definition compared to the laser one, for qualitative results completely comparable to HD printing heads present on HP sheet-fed machines. “The V12 was presented last September and in recent months the machine has been further improved, also thanks to the 5 beta installations at some of our customers, who became protagonists of important records: 90 kilometers of reels printed in a single day, for 8 jobs and 20 references with 5 paper changes, just to name one”, says Fiorenzo Dosio, “and of these companies, 3 have asked us to explore with them the opportunity of purchasing a second machine, demonstrating that our predictions for the use of this technology in the label market were correct”.

LEPx printing technology, as well as for the label world, is also suitable for the flexible packaging market, as it is capable of printing on the entire wide range of materials that are typically part of the applications of this market segment, among other things growing. HP made its debut in this market with the 20k and then with the 25k and now the 200k, 30% more productive, for an installed base of 350 units in 50 countries and 200 factories. This machine, in addition to printing flexible packaging, allows label manufacturers to diversify their production, in fact together with its partner Karlville, HP has created the “Digital Pouch Factory”, to produce pouches in small runs, a very similar business model to that of labels since it is a market where you sell by piece, and not by weight like that of flexible packaging.

LEPx printing technology, as well as for the label world, is also suitable for the flexible packaging market, as it is capable of printing on the entire wide range of materials that are typically part of the applications of this market segment, among other things growing. HP made its debut in this market with the 20k and then with the 25k and now the 200k, 30% more productive, for an installed base of 350 units in 50 countries and 200 factories. This machine, in addition to printing flexible packaging, allows label manufacturers to diversify their production, in fact together with its partner Karlville, HP has created the “Digital Pouch Factory”, to produce pouches in small runs, a very similar business model to that of labels since it is a market where you sell by piece, and not by weight like that of flexible packaging.

Setting the stage for success with intelligent manufacturing systems

HP is defining the industry’s approach to automation through AI and robotics, introducing a complete print production automation ecosystem. Specific efficiency innovations include: PrintOS Production Beat support for analog printing and finishing equipment to control all production; HP Indigo PQ Maestro is an intelligent wizard at the start of the day to optimize press performance; with Preflight, thanks to AI, the most suitable printing mode is automatically prepared based on customer preferences; Advanced AAA 2.0 (Auto Alert Agent), a machine-learning algorithm that autonomously increases printing productivity. For more efficient production, HP offers Autonomous Mobile Robots (AMR) in collaboration with MoviĜo Robotics to automate media transfer, saving up to two hours per day for each press.

HP is defining the industry’s approach to automation through AI and robotics, introducing a complete print production automation ecosystem. Specific efficiency innovations include: PrintOS Production Beat support for analog printing and finishing equipment to control all production; HP Indigo PQ Maestro is an intelligent wizard at the start of the day to optimize press performance; with Preflight, thanks to AI, the most suitable printing mode is automatically prepared based on customer preferences; Advanced AAA 2.0 (Auto Alert Agent), a machine-learning algorithm that autonomously increases printing productivity. For more efficient production, HP offers Autonomous Mobile Robots (AMR) in collaboration with MoviĜo Robotics to automate media transfer, saving up to two hours per day for each press.

Developed in collaboration with printers and converters, HP also announces the launch of the HP Sustainability Amplifier program, which helps accelerate the sustainability program and offer more sustainable printing, in collaboration with HP’s Sustainable Impact Strategy, aligns with the commitment of HP towards renewable energy and the reduction of CO2 emissions.

“Welcome to the next 20 years”: discover the future at drupa in Hall 17

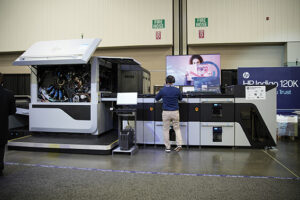

At drupa 2024 in Hall 17, the global HP printing community will see eight automated production lines featuring the latest innovations from HP Industrial, involving more than 25 partner companies and including more than 20 unique automation solutions.

“In the online world with social media everyone may seem like a king, but it’s at events like drupa that you understand who really dominates the industry. When you see the size of the stand, perceive the number of machineries, the quality of the samples and equipment and learn about the collaborations with all our partners, only on these occasions can HP’s true leadership be grasped. It’s a really great opportunity for us to showcase who we are to the industry, alongside of course the many other marketing activities we do. Drupa is like a clockwork, a deadline that comes every four years. It takes time to develop machines and innovations and you know that at drupa you will have to be ready, because everyone is waiting for you. The palpable energy and enthusiasm are, in fact, an indicator of the fervor that accompanies the wait of many people to learn about the latest news and perhaps make their purchases. And so, it’s not just a marketing activity, it’s also a sales activity”, said Eli Mahal, Head of L&P Marketing, HP Indigo, with whom we exchanged some opinions during the DScoop event in Indianapolis.