Flexo srl is an Italian flexible packaging printing company that has grown remarkably fast since it was established in 2006. So much so that in 2020 the company decided to expand its activities by setting up a brand-new in-house lamination department to complement their flexo printing operations, investing in a solventless BOBST SX 550 LAMINATOR.

A brave move under the current times which made the selection of machine that would best serve their purpose even more important given that in-house production of laminated flexible packaging was an unchartered territory. Dante Cantinotti, the company founder commented: “We looked for a partner with an all-round experience in laminating in terms of both equipment and process that we felt we could rely upon while undergoing a change that would extend our production capacity and more importantly reduce our response time to our clients”.

A family-owned concern, Flexo srl, is located in Biella, in northwestern Italy, and specializes in the production of flexo printed flexible packaging serving primarily the food market segments.

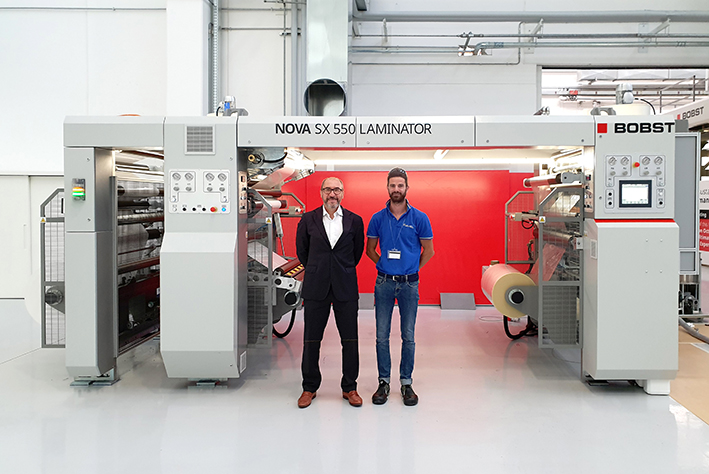

Marco Cantinotti, Production Manager and owner of Flexo srl, has been heading this expansion project and is very appreciative of the experience with the NOVA SX 550 since the laminator was commissioned in July 2020. “The experience has been very positive on two levels: the support provided by BOBST as we began this new journey and the capabilities of the machine itself” he commented “Up and running in just one week, it is a true plug and play solution which made everything not only extremely simple but of course it allowed us to be functional and producing laminates in a very short space of time. And the quality of the solventless laminated duplex structures is excellent”.“Lamination equipment was new to us and we were concerned about the “teething phase” on the part of our operators. However, they pick-it up very quickly,” he continued.

The NOVA SX 550 design is user-friendly and the fully integrated HMI intuitive and easy to use to set the machine up, and to display, store and recall all job recipes. The laminator also features other automations, like the onboard washing, that facilitate and speed up the operator’s job. All machine areas easy to access to make daily operation and maintenance activities simple.

“The NOVA SX 550 has marked the opening of a new chapter in our company history. Six months into production we can say that the premises are all there to enable us to confidently look forward to growing further and being able to further invest”, concluded Marco Cantinotti.