Flexo Day 2024 organized by Atif brought together more than 500 operators of the flexo community in Milan. An opportunity for technical updating with several focuses dedicated to corrugated board, discussions, networking; during the gala evening the Best In Flexo award ceremony was held to honor excellence in flexographic prepress and printing. Toppazzini with the help of Carminati prepress won Best In Show 2024 award

It is definitely the event of the year, eagerly awaited by the entire printing industry and beyond, able to call together more than 500 people from the flexo and packaging community, not only from Italy but also from the rest of Europe. We are talking about Flexo Day and Best In Flexo, the Atif-branded event that in two days brings together the operators of the supply chain for economic, strategic and technical updating, with the evening celebration of Best In Flexo that rewards excellence in prepress and flexo printing.

This edition was the first as Atif president for Andrea Dallavalle, who is proud to be at the head of a perfect organizational machine that year after year, thanks to the invaluable work of Monica Scorzino in the lead but also Deborah Rizzo, Ruggero Adamovit and all the Atif staff, always manages to attract the audience of great occasions.

During the Flexo Day and thanks to the opportunities for the players in the supply chain to meet, knowledge is shared, relationships are strengthened between suppliers, printers and brand owners, the latter certainly the most interested in learning more about the potential of flexo printing process.

Flexo Day summary- Session 1 – Market scenarios, PPWR and the role of packaging, success stories

Fabio Papa, Scientific Director of I-AER, Institute of Applied Economic Research, who last year with his talk left little hope on 2024, this year presented himself with a talk titled “Evolve or die out: how to survive the coming 2025”, thus leaving the door open to positive glimmers, but we have to work hard, knowing that in any case the scenarios of the past will never return (see for example interest rates at Covid level). Papa’s ever-appreciated speech is really true, as we are in a historical moment where it is no longer possible to pretend that nothing is happening. While there are economies in the world that are growing, it is equally true that there are others, in Europe and therefore Italy, that are struggling. Italy is back to 2019 levels, in a situation of substantial stagnation, partly due to an economy linked to Germany that has big problems.

Hence some useful suggestions for 2025: don’t make crazy investments, optimize the existing and work on the future of the company, valuing the people in the company, and rejuvenating companies by accelerating the generational transition. If these things are not done, the company will lose competitiveness overall. Therefore, there is no need for Artificial Intelligence but for Entrepreneurial Intelligence.

Alberto Palaveri, Giflex president, told what the role of packaging could be considering PPWR, pointing out the role of flexible packaging, which is light and with little material can pack and transport a lot of products, thus perfectly in line with the demands of PPWR which however contains some positive and challenging elements that need answers: no to superfluous packaging, reduction and weight of materials and where possible evaluate refill options. It is essential to think about answers already in the planning and design phase. Giflex this year devoted a lot of space to communication with more than 70 events, because as Palaveri reminds us, it is essential to make the role and values of packaging known and communicated outside the supply chain, especially among end consumers.

For the “Business Stories” section, Armando Garosci, moderator of the first session, interviewed Elisabella Brambilla, president of Eurolabel with about 80 collaborators, the female protagonist of a beautiful entrepreneurial story in the self-adhesive labels sector, which has always made fairness, sustainability and ethics towards collaborators, customers and suppliers one of its founding values. Elisabetta told a nice anecdote: she recalled that her father was a cousin of Angelo Bartesaghi, founder of OMET, which then built machines for the production of napkins. Together the two cousins built what was in fact the first OMET machine dedicated to print self-adhesive labels, in operation until a few years ago at Eurolabel. Clearly, the label was in the company’s DNA. In closing remarks Elisabetta Brambilla, who among the many things she is involved in, also runs a course at ITS Rizzoli in Milan, told how young people often do not give the packaging sector the right value until they enter companies, discovering a reality made of very high technology and high specific skills.

Two speeches were given by sponsors. Inci.Flex with Giuseppe Tripaldi who recounted the company’s history and growth with several acquisitions both in the flexo sector for flexible packaging and corrugated board and in the gravure sector, bringing the company to have today 160 employees, Last October 4 Inci.Flex organized an international event to present the latest technological innovation developed in partnership with Esko, the CDI Crystal Quartz Edition for the pursuit of absolute quality in flexo printing. Alberto Vaglio Laurin, BOBST, presented the multinational group active in the flexible packaging, corrugated cardboard, folding carton and label markets, with 19 production sites and a global presence in more than 50 countries worldwide. In Italy there are two Competence Centers, one in Florence dedicated to the label sector and another one in San Giorgio Monferrato for gravure printing and converting.

Flexo Day summary – 2nd Technical Session with focus on corrugated board

The second day, moderated by Chiara Bezzi, Editor-in-Chief of Rassegna dell’Imballaggio, opened with a speech by Atif president Andrea Dallavalle, who provided some insights into how the packaging market may evolve next year. Among the challenges for flexo printing certainly sustainability with sustainable and recyclable packaging materials, inks without organic volatile solvents, low consumption UV LED curing, barrier coatings for single-material packaging, and a reduction in machine energy consumption, but also less waste and reduced material consumption, substantially lighter packaging, and above all elimination of over-packaging. Flexo as a very flexible technology is suitable for a variety of applications and materials and will be able to provide important answers to the needs of hybridization with other printing technologies and respond to the evolution of packaging, especially Smart solutions for variable data marking, anti-counterfeiting and digital communication between brands and consumers.

Gianni Amendola for the Atif Technical Committee presented a report on inking systems with chambered doctor blade, that must be considered a crucial element of the inking system, one of the most complex processes to manage on press also because of the different variables to be considered. The chambered doctor blade is that component that helps to keep the printing process as standard as possible, it is transversal to different markets, not only flexo printing, but also coating,  tissue, offset printing and all those applications where is required the transfer of a fluid inside anilox microcells, while Giuseppe Gianetti on behalf of FTA Europe delved into the skills needed for printing on plastic film, also in the light of the new materials on the market today.

tissue, offset printing and all those applications where is required the transfer of a fluid inside anilox microcells, while Giuseppe Gianetti on behalf of FTA Europe delved into the skills needed for printing on plastic film, also in the light of the new materials on the market today.

Atif Technical Committee presented the plate pack for post print of corrugated board with a joint talk by Eno Tordini, Gianni Romano and Angela Conti, analyzing the characteristics of this packaging material, invented in America in 1871 and today one of the most widely used materials in the packaging sector thanks also to its sustainability due to its nature, and then discussing printing systems, the related issues, and finally analyzing prepress and the preparation of “sheets” and all the pre-mounting operations and tips for proper mounting up to the washing and proper storage of photopolymers, with a focus in particular on the usefulness of cushions, which in the face of the reduction in the thickness of printing matrices (2.84 mm is now the standard in corrugated board printing), assume a role of fundamental importance for the printing quality of both images and the finest texts, even on low quality substrates.

Wim Buyle and Stefano d’Andrea on behalf of FTA Europe, played a nice little show entitled “You should have told me before…” providing useful tips on how to optimize the management of the flexo system, assuming that if a lot of the information was known before putting jobs on press, many of the problems could be avoided or at least solved in advance to the benefit of quality, productivity and repeatability. Helpful tips on handling anilox, doctor blade, plate, double-sided tape, substrate color, characterization for each type of print substrate, ink, cleaning and maintenance interventions, which are not the same thing, that can help printers make a difference to get a quality, repeatable over time production. Knowing the rules of the game is important for managing the printing system, just as it is equally important to share straight away the printing conditions and to be able to possibly intervene and correct before starting to print, because as Stefano d’Andrea often reminds us, “the skill is not in knowing how to solve problems but in making sure they don’t occur”.

Three sponsors had a space to present their innovations.

Ira Nicoletti, Diaven, in collaboration with Marco Scatto, presented YOYO, a very interesting project, aimed at the recovery of flexo photopolymer processing waste, that, with a special filler, can become thermo-setting materials and thermoplastic resins for the creation of new objects. Ira’s call is for all interested companies to create an alternative supply chain and new business opportunities, in full compliance with environmental and circularity regulations.

Sun Chemical with Egidio Scottini spoke about inks, adhesives and coatings for flexo printing with a focus on nitrocellulose-free products that create problems during recycling. Today, ink manufacturers are part of an ecosystem where products act in relation to other products and materials, so it is crucial to have a holistic view especially from an end-of-life perspective.

Finally, Mattia Carpinetti, Uteco, compared the merits and demerits of flexo and digital printing, proposing the latest innovation at Uteco, a flexo-digital machine capable of offering a productive system, with reduced start-ups for printing personalized and variable data packaging.

Awarded as part of the BestStudentinFlexo 2024 JIA Stefano Rosso of the CNOS-FAP institute in Turin Valdocco, promoted by Atif – ENI-GCT – Atif Technical Commission with the support of I&C-Gama.

Best In flexo 2024

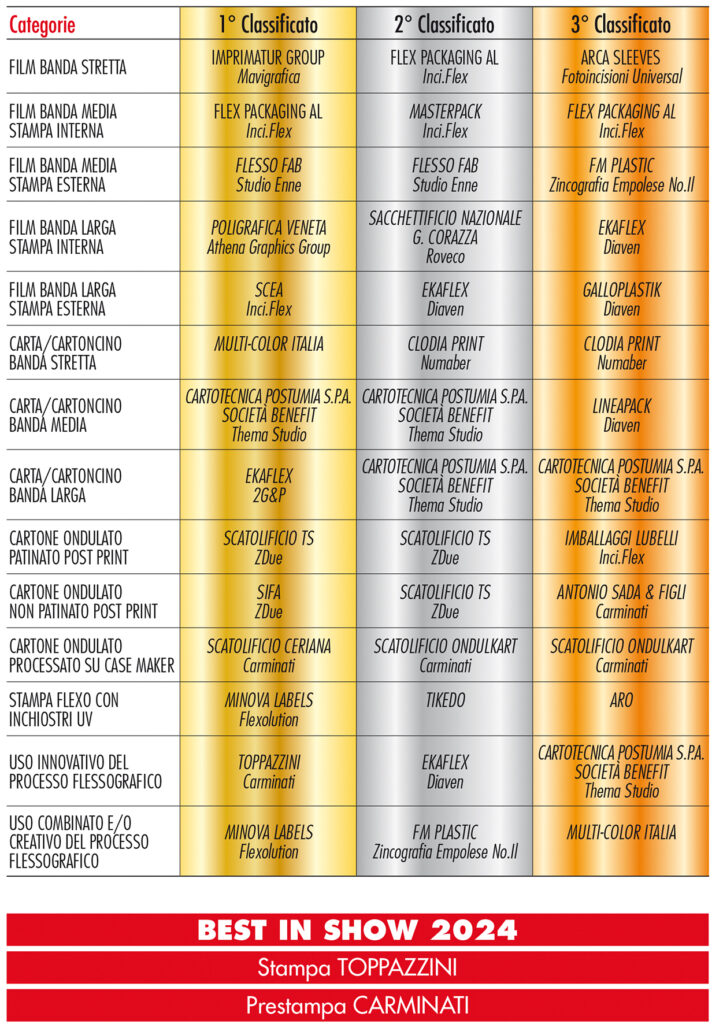

Tasty interlude between the two sessions of Flexo Day speeches, a gala dinner: held on the evening of November 13 for Best In Flexo 2024 awards, to recognize flexographic printing quality in 14 competing categories.

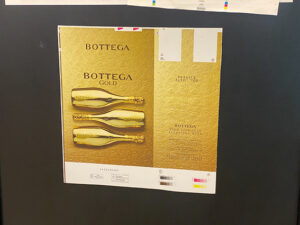

We publish the list of all the awarded companies and congratulate the competing printing and prepress companies for their achievements, especially the Best In Show 2024 that went to Toppazzini with the support of Carminati prepress, first in the Innovative Use of Flexographic Process category and selected as the best of the entries among all those competing. This is the motivation of the jury, for a work with a great visual impact: “excellent register, correct color lay down and printing of the highlights, good legibility and cleanliness of the texts, softness of the nuances, remarkable the effect of continuity obtained between front and back and the background texture, almost material that gives particular realism to the printed subject resulting from an evident work of study and enhancement of the chromatic effect, considering that was used only a four-color process”.

This year’s winners will participate together with next year’s winners in the FTA Europe Diamond Awards to be held in 2026.