An essential element is the ability to manage all products and business processes with a single software. Packway Technical Data Sheet, Production Planner, Data Detection from Machine board and Warehouse Logistics modules are decisive, interconnected in a 4.0 perspective with the factory machinery, necessary to obtain instant management analyzes and precise management control

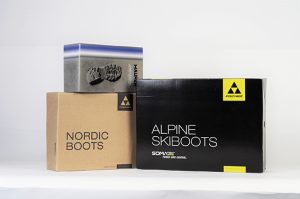

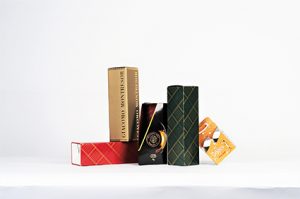

With a tradition that has its roots in the early twentieth century, Europoligrafico S.p.A. over the years has developed in-depth skills in the packaging sector, to become one of the leaders of the Italian market, boasting a significant presence also at international level.

Over a hundred years of history have seen the company grow and develop over time, through the merger of some specialized companies in the sector. The original nucleus is identified in the companies Poligrafico Buitoni and Grafiche Capretta, a leading company in the Italian cardboard industry, from whose union the current Group was born in 1999. Subsequently, with the acquisition of Aticarta, Europoligrafico integrates and completes its wealth of experience and technologies. Since 2006 the group has been owned by the Colleoni family, which is directly involved in corporate governance.

The management and administrative headquarters are in Verona, while the group’s production is organized on two sites, Treviso and Perugia, employing a total of 200 employees and developing a turnover of 53 million euros in the last financial year.

The marked trend towards innovation allows the Group to diversify its products, both in the creative sphere and for use on an industrial scale. The reference sectors are: food, general packaging, cosmetics, pharmaceuticals, beverage packaging, polylaminates, packaging for detergents and tobacco.

The company has first-rate technologies. The technical office is equipped with the most modern and specific software for structural design, graphic design, cutting plotter and computer to plate up to 110 × 160 format.

The printing department consists of four 6-color offset machines + varnish, from 70 × 100 to 110 × 160 format, a 10-color flexo machine and two 8 to 10-color gravure machines.

The printing department consists of four 6-color offset machines + varnish, from 70 × 100 to 110 × 160 format, a 10-color flexo machine and two 8 to 10-color gravure machines.

There is a special extrusion line for polylaminate products and a corrugating/laminating line for different types of laminates for the production of microwave packaging. The die-cutting department is equipped with 6 autoplaten from 70 × 100 to 110 × 160 format.

The finishing consists of 6 folder-gluers, 1 assembler, 1 rewinder, 1 cutter plus special packaging machines, that is doming machines for panettone, pandoro and other cakes cases, forming machines for the construction of various cardboard structures and other patented ad hoc machines, integrated with palletizing robots arranged at the end of the line.

Face to face with Edoardo Colleoni – Titolare Europoligrafico S.p.A.

How has the relationship between Europoligrafico and B+B International developed over the years?

“We have been collaborating with B+B International for many years. We started from the technical office, initially with the ArtiosCAD & plotter Kongsberg design software in Perugia, followed by ArtiosCAD & Kongsberg plotter in Treviso, after which we started the management of pre-production with CRM module and management of the technical office. Finally, we completed the software automation process by implementing Packway management software in all its modules.

“We have been collaborating with B+B International for many years. We started from the technical office, initially with the ArtiosCAD & plotter Kongsberg design software in Perugia, followed by ArtiosCAD & Kongsberg plotter in Treviso, after which we started the management of pre-production with CRM module and management of the technical office. Finally, we completed the software automation process by implementing Packway management software in all its modules.

In this last phase there was a deep integration with the factory, which is undoubtedly the beating heart of a cardboard converting company. This fully computerized management under the direction of a single computer system has allowed us to achieve the corporate governance and control objectives through management analyzes and almost immediate reporting, this was the main reason of such a demanding investment as the change of the management system.

What was the software architecture used before using Packway?

“The software used since the 1990s was based on AS400, developed for Treviso site and then implemented in the early 2000s also in Perugia, mainly focused on the operational management of the company. As for administrative and accounting aspects, on the other hand, we used locally developed software, connected to the AS400 system. Although that software architecture had supported us for several years, the awareness that we had to change step gradually grew in us, it was clear the need to have a modern, specific software that would really allow us to fully manage the company in all its areas, especially in production and obtain significant data in real time”.

What led to the installation of the new management system?

“For the period 2019-2022 we had developed a rather ambitious investment program in machinery which included a new offset printing machine, two autoplaten, a new corrugating/laminating machine and the transfer of Rotoconvert to Treviso.

“For the period 2019-2022 we had developed a rather ambitious investment program in machinery which included a new offset printing machine, two autoplaten, a new corrugating/laminating machine and the transfer of Rotoconvert to Treviso.

We were then convinced that in order to make full use of the huge investments in production, we had to intervene equally heavily in the automation of processes and in the organization. For this reason, 2021 was entirely dedicated to the inclusion of the new Packway management software”.

What was the path and where did you start from?

“We relied on B+B both for the specificity of the Packway software to manage a packaging company but also for the skills of their consultants and the methodologies applied during the start-up plan.

We started from the end, that is from the management analysis and from the reporting that I wanted to obtain, in short, from the main objectives. We tracked down what needed to be done to achieve those goals. All the technical and operational choices have been made to achieve the final goal.

It is now very clear that this was primarily possible thanks to Packway’s Graphic Technical Data Sheet, that is the ability to manage all the raw materials and all the working centers necessary for the production of one or more items, with all the relevant variables such as the production of products made with multiple materials and different production cycles, mix of different subjects on a press sheet, management of subcontracting, management of sheet or reel materials, units of measure per meter or kg, etc…

All this information is necessary for proper commercial management, estimates and orders, but also for the analysis of needs, purchases, goods receipt and management of raw material warehouse.

The set of all the information contained in these applications, when transmitted to the Production Planner, allows the coordination and total control of the production area. Through the detection of data from machine board it is possible to know in real time what is happening in the factory, allowing the planner to always act in real time.

The set of all the information contained in these applications, when transmitted to the Production Planner, allows the coordination and total control of the production area. Through the detection of data from machine board it is possible to know in real time what is happening in the factory, allowing the planner to always act in real time.

The system integrated with the warehouse logistics allows traceability by pallet, as well as a timely verification of semi-finished and finished product in warehouses.

Using the shipping application it is possible to optimize the loading and delivery plans, which integrate directly with the eSolver accounting system of Sistemi S.p.A., supplied and assisted directly by B+B.

I do not deny that the path was in various respects also tortuous, in some moments complex because we had to intervene on the organization, on the change of duties of some operators and on the insertion of new people and on the demolition of consolidated procedures that unfortunately did not generate more value.

The integration between the offices and the factory was very strong because all the plugs must be inserted in the correct position. People weren’t used to being blocked because a data was missing.

In fact, once upon a time we went ahead even without all the information in their place, and this, which at first appeared to be a flexible and efficient method of doing things, was actually the main reason for which cost management and control of the warehouse situation were lost. For these reasons, we believe that a project of this nature can only be tackled with the direct involvement of the company management. With Packway, the process is currently managed at 360° and the results achieved justified the efforts and investments made”.

How was the installation of Packway technically carried out in support of multi-factories dynamics?

“The Packway installation resides on a single cloud server while all the applications dedicated to production are physically installed at production factories. The management of the departments within the factories has been activated, allowing Treviso to have the Cardboard & Rotoconvert division while in Perugia, Cardboard & Flexible Packaging. All production is coordinated by a single Production Planner divided into the 4 departments, allowing high automation in the exchange of orders/processes between the various factories. Data collection takes place in real time with the terminals on the machine and 4.0 interconnections with all the new generation machines, including integration with two different palletizers.

“The Packway installation resides on a single cloud server while all the applications dedicated to production are physically installed at production factories. The management of the departments within the factories has been activated, allowing Treviso to have the Cardboard & Rotoconvert division while in Perugia, Cardboard & Flexible Packaging. All production is coordinated by a single Production Planner divided into the 4 departments, allowing high automation in the exchange of orders/processes between the various factories. Data collection takes place in real time with the terminals on the machine and 4.0 interconnections with all the new generation machines, including integration with two different palletizers.

Very in-depth management of the activities carried out for processing and strong synergy with third-party companies, allowing them to directly use some Packway applications.

Logistics and warehouse management are fully automated for raw materials, semi-finished and finished products. Through the use of internal applications that allow the exchange of data in electronic format, it was possible to integrate both with customers but also with suppliers by tracing the single pallet/reel.

The reporting, management control and management analysis systems are centralized directly from Verona office and based on Microsoft Power BI, as the general accounting installed with a multi-factories profiling”.

What is the impact of the Digital Transformation?

“The investments made in the last three years have strengthened and accelerated our improvement process. However, it should be recognized that the investments necessary to concretely realize the “Digital Transformation” are in some respects diametrically opposed. The installation of a new printing machine or an autoplatine requires an important investment economically, but at the level of people’s commitment it is rather limited, in fact we are talking about 10, 15 operators involved. The inclusion of the new management software has an economic impact that is much lower than that of a printing machine, while the involvement of the staff is much more relevant, in our case it directly and indirectly involved all 200 employees of the company”.

“The investments made in the last three years have strengthened and accelerated our improvement process. However, it should be recognized that the investments necessary to concretely realize the “Digital Transformation” are in some respects diametrically opposed. The installation of a new printing machine or an autoplatine requires an important investment economically, but at the level of people’s commitment it is rather limited, in fact we are talking about 10, 15 operators involved. The inclusion of the new management software has an economic impact that is much lower than that of a printing machine, while the involvement of the staff is much more relevant, in our case it directly and indirectly involved all 200 employees of the company”.

What is your quality policy?

“In a context in which attention to the environment is becoming increasingly important, the Group defines objectives and programs relating to the management of its environmental policy.

Europoligrafico also confirms its commitment to forest sustainability in compliance with the FSC-CoC standard. The company carries out a systematic assessment of its performance with a view to continuous improvement, aimed at safeguarding the environment. The management considered it a duty to adopt a Code of Ethics to formally outline, in a clear and binding manner, commitments, principles and business protocols according to an increasingly transparent and effective organizational model.

A cornerstone of the organizational structure is respect for health and safety in the workplace, in addition to SMETA 4 Pillar and EcoVadis schemes.

Finally, full compliance with ISO 9001 standard, BRC/IoP Global Standard and FDA as regards food safety, not only as reference standards, but also as real company policies, offers further guarantees to products and offered services. All the certifications mentioned above are managed with the Packway management software”.

What will be the next implementations?

“We performed a predominant integration activity with all production machines, which certainly had higher costs and times, but the return of the data is qualitatively superior and absolute. This has allowed us to enter into the logic of industry 4.0 and all the benefits that it entails at an operational level. In these days we are starting a new project for the implementation of quality controls directly from the machine and in the scheduled management of plant maintenance, always within Packway.

“We performed a predominant integration activity with all production machines, which certainly had higher costs and times, but the return of the data is qualitatively superior and absolute. This has allowed us to enter into the logic of industry 4.0 and all the benefits that it entails at an operational level. In these days we are starting a new project for the implementation of quality controls directly from the machine and in the scheduled management of plant maintenance, always within Packway.

Today a large part of our turnover is in the food sector and consequently the certifications with which we operate oblige us to have a traceability system that in fact also has legal implications, so this process integration is absolutely essential. Our customers are leading us in this direction and through the implementation of Packway we plan to be up and running before the summer”.