Even at the last edition of BestInFlexo 2023, the collaboration with DuPont is behind the success of several prepress companies. In the flexographic industry this is synonymous with plates and technologies for the production of photopolymers that are used daily by photolithologists to support their customers in successful projects, exactly as happened at the last Atif competition.

Success never comes alone, but above all it is never a coincidence or the merit of a single component. Like any successful recipe, if you start with a high quality product and you know how to cook it properly, the final dish can only be superb. And this is exactly what frequently occurs at BestInFlexo, where DuPont, with its products and technologies for the flexographic industry, supports several Italian prepress companies in their successful path with their respective printing customers.

Success never comes alone, but above all it is never a coincidence or the merit of a single component. Like any successful recipe, if you start with a high quality product and you know how to cook it properly, the final dish can only be superb. And this is exactly what frequently occurs at BestInFlexo, where DuPont, with its products and technologies for the flexographic industry, supports several Italian prepress companies in their successful path with their respective printing customers.

Each flexo photolith that was awarded in the various categories, including the BestInShow won for the second consecutive year by a company that chose DuPont plates, has its own “secret recipe”, procedures, small and large tricks that can make the difference on the final result, but each one started from the same point: Flexo photopolymers by DuPont.

Each company has succeeded in using a high-quality raw material and in adding its own know-how to offer customers a product that, once printed, has also stood out as winning in the eyes of an independent jury.

“Italian prepress companies are all top-level companies, each one with its own structure, strategy, organization. We are dealing with companies, from the smallest to the largest ones that also compete on international markets, that today are able to support the world of flexo printing with high quality solutions, and we, as a world leading supplier, are very happy to be able to contribute to those results that reward excellence and the quality of flexo printing. Being considered a benchmark for the pursuit of quality – in an increasingly competitive market where there is no shortage of innovative products, technologies and solutions – makes us happy and proud and encouraging us to continue investing to offer the market innovative, high-performance and sustainable solutions,” says Mario Castelli, Sales Manager Printing & Packaging – Cyrel® Solutions Southern Europe and Northern Africa Industrial Solutions.

“Italian prepress companies are all top-level companies, each one with its own structure, strategy, organization. We are dealing with companies, from the smallest to the largest ones that also compete on international markets, that today are able to support the world of flexo printing with high quality solutions, and we, as a world leading supplier, are very happy to be able to contribute to those results that reward excellence and the quality of flexo printing. Being considered a benchmark for the pursuit of quality – in an increasingly competitive market where there is no shortage of innovative products, technologies and solutions – makes us happy and proud and encouraging us to continue investing to offer the market innovative, high-performance and sustainable solutions,” says Mario Castelli, Sales Manager Printing & Packaging – Cyrel® Solutions Southern Europe and Northern Africa Industrial Solutions.

Among other things, in 2024 Cyrel® plates will celebrate their fiftieth birthday and what better opportunity to start celebrating the success of a product that has always been a point of reference in the flexographic industry. The first worldwide commercialization of Cyrel® photopolymer plates took place in 1974. Certainly, flexography has made great strides today, and is probably the printing technique that evolved the most in the last 20 years, also thanks to the evolution of materials and prepress technologies. In fact, it is fair to mention that today, in the face of a state-of-the-art printing machine, excellent results are achieved using an excellent flexographic matrix.

Among other things, in 2024 Cyrel® plates will celebrate their fiftieth birthday and what better opportunity to start celebrating the success of a product that has always been a point of reference in the flexographic industry. The first worldwide commercialization of Cyrel® photopolymer plates took place in 1974. Certainly, flexography has made great strides today, and is probably the printing technique that evolved the most in the last 20 years, also thanks to the evolution of materials and prepress technologies. In fact, it is fair to mention that today, in the face of a state-of-the-art printing machine, excellent results are achieved using an excellent flexographic matrix.

Companies will still have to face many challenges, even under strong market pressures, especially with the sustainability demand.

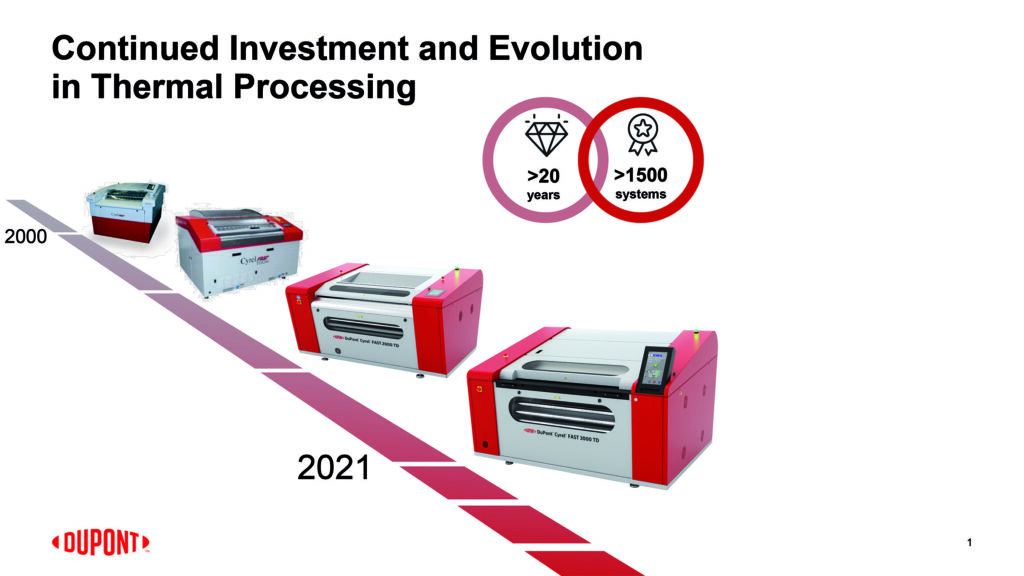

“We are also pleased that companies using both our DuPont™ Cyrel® Fast and solvent thermal systems have been rewarded. Our customers are people who believe in what they do, but, above all, they do it with a lot of passion, demonstrating every day that flexography is a sector in which you can continue to grow. Whenever the bar of challenge has been raised, the limits have been overcome, obtaining excellent results”, adds Castelli.

DuPont Journey to Sustainability

The goal of sustainability cannot and should not be reduced to a mere marketing operation, in fact we know that today’s market does not forgive those who use this topic just to try to give their company a “footprint”. Sustainability is a mission that every company and every person must pursue to protect and preserve the environment for future generations.

Of course, DuPont is not backing down and, in fact, it has made a concrete commitment by setting goals such as the reduction of direct and indirect greenhouse gas emissions by 2030, to reach zero emissions by 2050.

“DuPont™ Cyrel® is committed to continuously developing solutions and technologies to reduce the environmental impact of products and to provide our customers with a workflow in line with the above-mentioned goals for both solvent and thermal systems. We are developing several projects to provide more efficient systems, workflows and consumables to help our customers improve their environmental footprint as well. And today this is increasingly becoming an effective sales tool for the end customer” says Castelli.

According to the latest update of the LCA (Life Cycle Assessment), for the manufacturing technologies proposed by DuPont, the Cyrel® FAST thermal workflow produces 38% less CO2 than a solvent-based workflow. In order to meet the needs of customers who use solvent processing to produce their plates, DuPont has developed a new solvent, Cyrel Flexosol-X®, which uses more sustainable components, reducing VOC emissions by up to 50%.

Towards Drupa 2024

“We are all eagerly awaiting the return of Drupa, and of course we will too attend the fair in Düsseldorf where we will present the latest innovations for both the thermal and solvent product portfolios. Our projects will enable our customers, present and future, to produce high-quality plates with a great vision for sustainability and very high speed of execution” Mario Castelli concludes.

The winners’ testimonial

1 – What were the key elements that contributed to the victory?

2 – What was the added value given by materials, technologies and more generally by collaboration with DuPont?

3 – What is your commitment to sustainability, and what plans do you have for the future?

2G&P

1 – Certainly, solids with very small negative texts and delicate shading. In two cases the job was carried out in four colors and one of these had previously been printed with gravure. Solids printing and brilliance of the colors with the maintenance of clean and soft delicate shadings were indispensable conditions. In the case of jobs with only four-color process, the microcells developed by us have made it possible to reach the densities essential for achieving the correct depths and correct color tones, without however affecting the cleanliness of lights and shadings in minimum printing dots.

1 – Certainly, solids with very small negative texts and delicate shading. In two cases the job was carried out in four colors and one of these had previously been printed with gravure. Solids printing and brilliance of the colors with the maintenance of clean and soft delicate shadings were indispensable conditions. In the case of jobs with only four-color process, the microcells developed by us have made it possible to reach the densities essential for achieving the correct depths and correct color tones, without however affecting the cleanliness of lights and shadings in minimum printing dots.

2 – LED exposure technology and Pixel Plus engraving certainly made the difference in achieving the right color tones improving transfer and dots and microcells building. As regards materials, all the awarded systems were made with Dupont™ Cyrel® plates. Our collaboration with them is now well-known and historic. We were the first to believe in their Cyrel® FAST thermal technology and we are still using it with great satisfaction.

We were born with that technology and today we are the only ones to have three production lines and the only ones to have a line in the maximum format. When we subsequently inserted the solvent lines, it was natural for us to rely on Dupont plates also in not-thermal version. Obviously, we have done tests with various materials but to date our production is 90% DuPont for plates and 100% for solvent.

3 – In the company we air-condition all the rooms with energy-saving inverter technology and the entire air conditioning system and the air exchange system of all the rooms are filtered upstream with activated carbon. Nearly half of our production is made with thermal material, without the use of solvents, resulting in an overall benefit of 38% less CO2 for DuPont™ Cyrel® FAST thermal workflow.

For solvent lines we use exclusively Dupont™ Cyrel® Flexosol X solvent which eliminates dangerous components as well as providing up to 50% less VOC emissions. We are completing the development of a management system that will soon lead to a further reduction in paper use until the complete elimination of paper forms.

DIAVEN

1 – Method, professionalism, customer knowledge, technical dialogue and loyalty. What was the added value given by materials, technologies and more generally by the collaboration with DuPont

1 – Method, professionalism, customer knowledge, technical dialogue and loyalty. What was the added value given by materials, technologies and more generally by the collaboration with DuPont

2 – As regards DuPont™ Cyrel® DPR material, the great guarantee of performance preserved over time and its ability to obtain excellent performance in flexible packaging printing. We consider the DPR a reliable plate. As regards the technologies present in our company, the possibility of digital control over the process which allows us to know the condition of the plate in each state of processing, digital control gives a data report that can be used by the customer as a quality guarantee of the delivered cliché. As regards our relationship with Dupont, our historical collaboration is dictated by our partner’s ability to guarantee a highly qualified service ready to support us with timely responses and to know how to create innovation together with us.

3 – Sustainability at Diaven is pursued at different corporate levels: our objective is well-being aimed at creating values in the business. Sustainability in the choice of an organized, efficient and digitalized production flow. Sustainability in the choice to reduce the impact of risk in production regarding safety in carrying out one’s work with latest generation machinery and in selecting each phase to make it safe and automated. Sustainability in providing a plan to reduce emissions, energy savings and intelligent consumption of material resources and machinery.

FLEXOLUTION

1 -The cleanliness of shadings and perfect fidelity with the color proof. The label was also made up of a 100% pantone with high coverage which then faded to 0. It was therefore possible to notice the perfect application and the softness and cleanliness of shading without streaks.

1 -The cleanliness of shadings and perfect fidelity with the color proof. The label was also made up of a 100% pantone with high coverage which then faded to 0. It was therefore possible to notice the perfect application and the softness and cleanliness of shading without streaks.

2 – Dupont™ Cyrel® FAST technology, in addition to extreme efficiency in terms of speed and therefore express service to the customer, allows us to create a plate with a low surface tension, to avoid over-inking in the thinnest points and at the same time guarantees us an excellent ink coverage. Plate inking is correct, and this allows us to produce long print runs, and its flexibility also allows better adhesion even on the smallest printing cylinders, reducing machine downtime to a minimum.

3 – Flexolution immediately adopted the FAST system to safeguard emissions and improve working environment conditions. Plans are certainly the expansion of our production site while maintaining this direction.

G.S. TIMBRO

1 – Combined use of the latest technologies on the market, i.e. flat top dot plate combined with the right algorithm in line with anilox and flow rate of the printing unit used, and exposure of the plate itself with LED technology.

1 – Combined use of the latest technologies on the market, i.e. flat top dot plate combined with the right algorithm in line with anilox and flow rate of the printing unit used, and exposure of the plate itself with LED technology.

2 – The link that combines the quality of DuPont™ Cyrel® plates, the technology with which they are processed, the partnership between the GS Timbro service and DuPont are fundamental to aim for a good printing result, so the added value is as high as the expectations.

3 – The commitment to sustainability has been part of GS Timbro for a long time, clearly the ever-changing times have led to increasing attention to new, greener production process systems such as the exposure of the plates with new LED systems and no longer with lamps or the increasingly constant use of low thickness plates even for printing on corrugated cardboard, with consequent less use of solvents used for washing the plates.

ROVECO

1 – Analyzing the work printed by PaganiPrint, we can state that contributed the excellent registration and ink transfer thanks to the FlexoHDPlus – S® flat top dot technology created by our company. This guaranteed excellent drafting on both process and pantone colors, high detail in the image and clean shadings to zero despite the high printing speed.

1 – Analyzing the work printed by PaganiPrint, we can state that contributed the excellent registration and ink transfer thanks to the FlexoHDPlus – S® flat top dot technology created by our company. This guaranteed excellent drafting on both process and pantone colors, high detail in the image and clean shadings to zero despite the high printing speed.

2 – The use of a Dupont™ Cyrel® polymer, our consolidated, reliable and historic partner, whose peculiar characteristics we know very well, combined with the use of our premium FlexoHD-Plus – S® technology has led to achieving excellent results. Having suppliers who are above all partners, such as DuPont, allows us to continuously test and develop new products to always keep up with the demands of our customers and to achieve goals of excellence recognized in the flexible packaging market.

3 – Roveco has always been committed to a responsible business model whose aim is guaranteeing sustainable development that is highly attentive to the health of the planet and the social and economic well-being of people. As regards the environment, we have adopted an innovative Dupont™ Cyrel® Flexosol-X solvent, we use forms of renewable energy and we have implemented energy efficiency improvements in offices and production departments. On an economic and social level, respect for people, safety in the workplace, justice and equality of our employees have always been our corporate pillars. We are also thinking of embarking on a path that will lead us to draw up a sustainability report.

STUDIO ENNE

1 – Certainly, the synergy of the group, the experience built over the years in this sector, the use of latest generation technologies and knowledge in flexo printing. But the lever that contributed most to the victory was having always believed in our greatest value, sustainability. In fact, from the beginning the objective we set ourselves as a company was to demonstrate that it is possible to achieve high quality in wide web film printing through plates made with sustainable DuPont™ Cyrel® FAST technology. This was the biggest victory for us.

2 – The latest generation technologies and the evolution of DuPont materials today represent an important technological development for quality and sustainability. The added value is always given by the man who is at the center of all these components. Our experience together with DuPont has shown us that it is thanks to the human factor that important goals can be achieved and today we can say that the experience gained over the years has turned into a great success in terms of excellence. In fact, last November 30th we received a prestigious recognition at Montecitorio, being among the 100 Italian Excellences 2023, winning the prize, “Stories of Excellence-100 Italian Excellences”.

3 – Our entire history is centered on sustainability. We can say that it began precisely with DuPont™ Cyrel® FAST technology, in which we saw the future, recognizing its great technological and sustainable potential from the beginning. Our biggest investment in this project was time and energy, years of study pushing skills, competences and experience to the maximum with the aim/dream of realizing a 100% sustainable production of printing plates, without the use of solvents. Today our commitment is investing constantly in technologies that benefit the environment, provide information and training, transmitting our experience and our enthusiasm to the new generations.

FOTOINCISIONI UNIVERSAL

1 – The key elements were the in-depth analysis of the job and then find the best solution to make the subject printable in flexography obviously taking into consideration the technologies at our disposal combined with the best polymer on the market for the printing substrate on which the packaging will be printed.

1 – The key elements were the in-depth analysis of the job and then find the best solution to make the subject printable in flexography obviously taking into consideration the technologies at our disposal combined with the best polymer on the market for the printing substrate on which the packaging will be printed.

2 – For the good result of a job, the technology used is of fundamental importance and above all the polymer, in this case DuPont™ Cyrel® which allows the graphics of the subject to be transferred to the print substrate in the best possible way.

3 – In recent years our company is increasingly moving towards the flexographic sector rather than the gravure sector, which has less ecological impact. In the future, therefore, the idea is to invest more and more in flexography with the inclusion of increasingly green equipment such as DuPont™ Cyrel® FAST.

ZINCOPAR

1 – The captivating graphics gave us the opportunity to make the most of the gamut expressed by the printer’s profile working meticulously and thus enhancing the image of the sunset over the mountains, even making some parts white.

1 – The captivating graphics gave us the opportunity to make the most of the gamut expressed by the printer’s profile working meticulously and thus enhancing the image of the sunset over the mountains, even making some parts white.

2 – The excellent result was guaranteed by the material used (DuPont™ Cyrel® ESX plates) combined with an internal Zincopar/Riflexo development, called ZPS, which guarantees a homogeneous four-color result and more.

3 – The Zincopar group, which has always been attentive to well-being issues, has implemented a series of interventions on its factories aimed, on the one hand, at the well-being of its collaborators with the installation of modern heating and cooling systems, air recycling and purification systems, on the other hand using ecological products for the processing of the latest generation photopolymer also supplied by Dupont; furthermore, we have just installed an innovative fume recovery system which will allow us to achieve environmental certification.