Several innovations have recently involved the Italian headquarters of DuPont, that moved to the new offices in the center of Milan after a technical and commercial reorganization.

At the same time, its customer Zincopar provided the DuPont plates to the printer SIT during the last edition of Best in Flexo, for the printing job that won the Best in Show 2019 and that is going to participate to the Diamond Award of FTA Europe next June during Drupa 2020.

At the same time, its customer Zincopar provided the DuPont plates to the printer SIT during the last edition of Best in Flexo, for the printing job that won the Best in Show 2019 and that is going to participate to the Diamond Award of FTA Europe next June during Drupa 2020.

The months between the end of 2019 and the beginning of 2020 have been very intense for DuPont Italy. The new corporate headquarters are now fully operative in a large space of 1.000 square meters in the heart of the city of Milan, responding to the need of the American multinational corporation to have a prestigious representative office that is easily accessible from the main communication routes, in an area which houses the headquarters of the most important national and international companies.

DuPont, founded on the cardinal principles of sustainability, respect for its collaborators and ethics, has also encouraged its employees to use the public transport, recognizing a transport bonus to all those who will not use the car to get to the Milan offices.

“One of our missions is the reduction of the environmental impact. Actions such as the transport bonus, combined with increasingly sustainable technologies and products follow exactly this direction”, says Mario Castelli, who has become Sales Director of the DuPont Advanced Printing division in the Mediterranean and North Africa area, taking the place of Francesco DeRoa, that the Italian market has known in the last years, since he has always been present at initiatives such as Flexo Day, the open houses or directly from customers with the Italian management.

“I accepted the new assignment with great enthusiasm, and it will lead me to travel more in the areas of my pertinence, and for this reason a reorganization of our department has been necessary, also because at the end of December, after 33 years of continuous service at our company, Ruggero Cordini retired.

He has been a colleague; a friend and we have experienced the growth of the company and of the flexographic sector side by side. I’m taking this opportunity to thank Ruggero publicly for his professionalism and his precious support. However, the customers should not worry because Riccardo Labianca will take the place of Ruggero, being the new Sales Manager of Northern Italy “, adds Mario Castelli.

The old role of Riccardo Labianca has already been assigned to Michele Negretti, the new flexo and ink specialist since January 2nd, an expert in the sector with several years behind him in the field of flexo. The DuPont team also includes Sergio Roccetti, Sales Manager for Central and Southern Italy, Carlo Sala, head of service for Southern Europe and Luca Cerofolini, ink specialist for Europe.

“These important investments for the new headquarters and for the high-level technical-commercial figures only prove the desire of DuPont to continue to support services and printers in their daily activities, with our high-level technological solutions and materials for all the needs of flexographic printing, from flexible packaging, to paper bags, from labels to cardboard, from shoppers to corrugated cardboard” adds Castelli, reminding that one of the flagships of DuPont is undoubtedly the “FAST” thermal development system, in line with the company’s green philosophy: in addition to having more than 1,500 installations, it allows a 53% reduction in greenhouse gas emissions compared to solvent plates, and a 63% reduction in energy consumption, combined with a reduction of up to 75% of the plate production time and it also optimizes repeatability and quality in the production of plates without the use of any liquid substance.

“As regards Drupa 2020, we will have some important news that will be revealed in a few weeks. We are going to be present with a stand and we will be happy to show our latest innovations for the packaging and digital ink sector to customers and visitors, a sector that is giving us remarkable satisfactions”, says Castelli in conclusion.

A record plate: Zincopar and SIT won the BestinShow2019

Great surprise, but also enormous satisfaction in Zincopar for the 5 awards received during the last edition of the Best in Flexo: the 1st place + Best in Show in the Film Media Band Internal Press category in support of SIT, the 2nd and the 3rd place in the Category Broadband Film External Print in support of Sidac, and the 3rd place in the Paper/Cardboard Medium Band category in support of Formbags.

“We participated with 8 works and 4 of them were awarded, including the praise of the Best in Show” says Massimo Cipolla, owner of Zincopar, historical trade shop company based in Parma, specialized in the supply of flexo printing systems for food & beverage customers.

The work named “Polpo con patate” is by a brand owner who is our direct customer, and was printed by SIT, with whom we have had a very close collaboration for some years. We also worked together to obtain the same rotogravure results in flexography, so that they can decide which printing technique to use, without any difference from the qualitative point of view.

Investing in the highest quality technology and in equally performing printing systems is essential to achieve this aim.

Investing in the highest quality technology and in equally performing printing systems is essential to achieve this aim.

For this work we used the HD-Full HD technology, engraving with in-line CDI on DuPont polymer. The entire image is obtained in four colors, with a very delicate vignette, so achieving balance is not easy.

Furthermore, in this case the Printer used very strong pigments that make it difficult to maintain the cleanliness of the vignette; the “Polpo con patate” seems to come out of the pan, thanks to a clear, decisive color scheme, with an almost three-dimensional effect.

So, it is not so easy to maintain a balance on all the graphics, in order to have the impact of the product and so that the clear parts remain clear. The DuPont plate we used was important because it guaranteed us an excellent transfer on solid area and at the same time, the maximum opening on the high lights” adds Massimo Cipolla, supported by the Prepress Technical Manager Francesco Davoli, who followed all the stages of this process and of the other awarded works directly.

“As regards the two works printed by Sidac, which obtained the 2nd and 3rd place, the challenge was to be able to work with some pantone, managing to achieve the goal without necessarily using the process colors. In this case the balance between the pantone made the difference.

Today, the available technologies allow us to customize the service offered to the various customers. Therefore, we should try to understand what is the best way to meet the customers’ needs from the beginning of the project.

Even the work that won the 3rd prize and that was printed by Formbags had several pitfalls, because, from a graphic point of view, there was an image with different blurring in the background while the main subject had to stand out.

Here, the print support, a kraft paper that absorbs a lot of ink, is undoubtedly one of the main difficulties; even in this case, the collaboration with the printer has been valuable to achieve optimal results.

It is not a coincidence that Formbags’ works are rewarded at every Best in Flexo, testifying the search for a constant quality over time” says Francesco Davoli in conclusion.

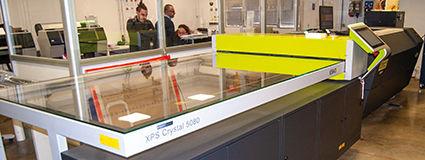

The search for quality imposes a policy based on continuous investments to the prepress service, in order to keep up with the times. Zincopar’s latest investments were the New PCW software for the screens management and the Exposure system Crystal XPS by Esko.

The Company also invested in the Environmental Certification that is going to obtain in March. Other investments will also concern Riflexo, a company acquired in 2017 and specialized in the production of corrugated cardboard printing systems, which will gradually have to use the same technologies and the same working philosophy as Zincopar.

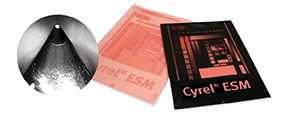

Cyrel® EASY ESM, the plate created for printing paper, but not only …

These new plates, with built-in flat-point technology, have been designed to obtain the highest quality image reproduction on multiple paper supports, making the operations easier both in the realization of the plates and in the press room.

These new plates, with built-in flat-point technology, have been designed to obtain the highest quality image reproduction on multiple paper supports, making the operations easier both in the realization of the plates and in the press room.

“The flat point of the ESM plate optimizes the ink transfer, with zero shades and bright highlights. The Cyrel® EASY quality allows to achieve excellent results also for printing on paper. We did some tests with some customers both on paper but also on plastic films and we achieved surprising results on both materials “, comments Mario Castelli to underline the extreme versatility of this new product.