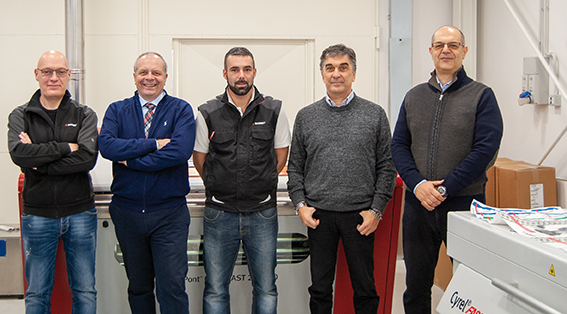

DuPont can boast a Competence Center that is unique in Italy, where you can make plates and print them, supported by a team of experts from DuPont and BOBST

The Competence Center of Bobst Firenze, the division of the Swiss multinational group dedicated to the construction of narrow-band printing machines, is constantly evolving, so much that it has recently been expanded and now houses as many as four BOBST printing machines for labels and flexible packaging in narrow-medium band. This technological Center is also the place where the REVO project partners can interact with their customers and use a printing press to test the performance of each component of the printing process. The Competence Center Team manages the entire printing process, from the pre-press to the production of the files, up to the final printing, with the interaction of all those technical components or materials that are part of the REVO project. “Back to Labelexpo Europe, the Competence Center hosts a MASTER M6 10 color for flexible packaging with the opportunity of changing works on the machine without stopping it, a MASTER M5 dedicated to label printing, the VISION M1 withmechanical shaft equipped with cameras for control and automatic registering, and finally the hybrid MASTER DM5, the perfect integration of 4 flexo units with the digital 6-colour unit.

The Competence Center of Bobst Firenze, the division of the Swiss multinational group dedicated to the construction of narrow-band printing machines, is constantly evolving, so much that it has recently been expanded and now houses as many as four BOBST printing machines for labels and flexible packaging in narrow-medium band. This technological Center is also the place where the REVO project partners can interact with their customers and use a printing press to test the performance of each component of the printing process. The Competence Center Team manages the entire printing process, from the pre-press to the production of the files, up to the final printing, with the interaction of all those technical components or materials that are part of the REVO project. “Back to Labelexpo Europe, the Competence Center hosts a MASTER M6 10 color for flexible packaging with the opportunity of changing works on the machine without stopping it, a MASTER M5 dedicated to label printing, the VISION M1 withmechanical shaft equipped with cameras for control and automatic registering, and finally the hybrid MASTER DM5, the perfect integration of 4 flexo units with the digital 6-colour unit.

The Competence Center is available to customers for testing the machines but also to REVO partners who can bring customers to Bobst Firenze for all the necessary tests. BOBST’s Florentine headquarters’ plan for next year is to make the Competence Center a training location not only open to customers but also to partners and suppliers to whom it is important to show the complete cycle, because the quality of the result depends not only on a single factor, but on a set of factors, technologies and components.

The Competence Center is available to customers for testing the machines but also to REVO partners who can bring customers to Bobst Firenze for all the necessary tests. BOBST’s Florentine headquarters’ plan for next year is to make the Competence Center a training location not only open to customers but also to partners and suppliers to whom it is important to show the complete cycle, because the quality of the result depends not only on a single factor, but on a set of factors, technologies and components.

The company’s after-sales service is always present during these visits to highlight quality, innovation and the latest IoT technologies.

Cyrel® FAST 2000 TD Thermal Development Line

DuPont is one of the partners in the project to produce flexographic photopolymers and has installed DuPont Cyrel® FAST 2000 TD, the maximum size 106.7×152 cm thermal development line, in the BOBST Competence Center in Florence.

DuPont is one of the partners in the project to produce flexographic photopolymers and has installed DuPont Cyrel® FAST 2000 TD, the maximum size 106.7×152 cm thermal development line, in the BOBST Competence Center in Florence.

The work cycle has been completed by the writing line ESKO Crystal + ESKO XPS and a cutting plotter Kongsberg for cutting photopolymers in the prepress department of the Competence Center, equipped with desktop workstations with the latest software for the preparation of graphic files.

“FAST® is our environmentally friendly flexo plate production system, with a 53% reduction in greenhouse gas emissions compared to solvent plates, and a 63% reduction in energy consumption”, says Mario Castelli Sales Manager Italy, Greece, Malta & Cyprus – Key Account Manager Digital Inks Electronics and Imaging – DuPont Advanced Printing. “Cyrel® EASY EFX digital plates with integrated flat point are used here at Bobst Firenze.

The high process control, the excellent product quality and the validity of this solution are also proved by the more than 1500 FAST installations worldwide. Combined with low emissions and a reduction of up to 75% in plate production time, the Cyrel® FAST 2000 TD is the ideal solution to combine productivity, quality and environmental sustainability. The plates provide high ink transfer and color saturation, allowing brighter images to be printed with finer print details and a wider color gamut.

One of the improvements made with the FAST 2000 TD is a sharper etching between graphics and counter graphics clearer than before. Processing thermally the new generation of Cyrel® EASY plates also ensures maximum ink transfer and resolution in extremely short times, without any kind of swelling, a problem that can occur in the solvent process. The working environment sees advantages immediately, because in the absence of solvents, there are no emissions into the atmosphere, and the problem of treating the residual solvent is eliminated. The few fumes that are emitted during the plate production process with Cyrel® FAST 2000 TD are immediately burned inside the machine that releases the residual air into the atmosphere. A reel of non-woven fabric is the only waste produced bythis machine. It has the task of retaining the polymer removed from the engraving process of the plate that is disposed of as industrial waste and not as special waste.

“Having this Competence Center at our disposal is very important for us, because we can make customized demos with our customers, who can touch the entire process of writing, engraving and developing the plate and even the final printing of their work on the BOBST printing presses if they request so. In less than half an hour we can move from plate production to printing and here we can prove it. All the customers we invited, both label and flexible packaging customers, were impressed by this structure and by the production process available to them”, says Castelli, not before remembering that thanks to the introduction of the first generation Cyrel® FAST processors on the market, DuPont has helped to reduce VOC emissions by about 98% compared to the solvent workflow.

The situation improved with the second generation Cyrel® FAST 2000 TD which has exceeded 99% VOC emissions compared to the solvent and more than 76% compared to the previous generation of thermal processors.

The situation improved with the second generation Cyrel® FAST 2000 TD which has exceeded 99% VOC emissions compared to the solvent and more than 76% compared to the previous generation of thermal processors.

“Sustainability, as well as safety, health, respect for people and ethics are the core values of our company, and the solutions that we are developing and that will increasingly be the focus of our business in the future, will go in this direction”, says Mario Castelli at the end.