Diaven and Ekaflex were the protagonists of a crackling 2023, full of novelties, and culminated with the success at Best In Flexo 2023. A success that comes from afar, and the result of a development policy planned by both companies, which led them to collaborate and develop a quality work. We talk about it in this article which shows great attention to training and human value, and in an in-depth video, where the protagonists of these two companies tell their partnership

Successes, such as the one obtained together with Ekaflex at latest Best In Flexo 2023, never come by chance and considering the path undertaken by Diaven, the flexo prepress company managed by the brothers Ira and Filippo Nicoletti, a clear message emerges: also a small/medium company located in a small province in the north-east of Italy, with 22 collaborators, can embark on a growth path and become a point of reference for flexo printing and converting market.

The company, specialized in the production of photopolymer clichés and engraved sleeves for flexography and dies for corrugated cardboard packaging, has in fact undertaken a growth path that has put people at the center of everything. Technologies are important and Diaven is absolutely at the forefront: a second Esko Crystal XPS display was recently installed which led the company to turn completely towards LED technology.

Also as regards the improvement of the service, agreements have been finalized with the elastomer producers to produce engraved sleeves, as well as various implementations at software level to continue with that corporate digitalization strategy which involved all company departments.

Furthermore, Diaven has already planned an important new investment during 2024 which will further improve its production capacity, enhancing quality and sustainability.

Three-year growth business plan: investments and people at the center

This development strategy arises from a three-year business plan that will see the company grow at all levels: technological investments and human resources.

This development strategy arises from a three-year business plan that will see the company grow at all levels: technological investments and human resources.

“For over 20 years we have been talking about company organization, lean production, spaghetti charts to modify people flows and optimize the process, controllers for cost accounting, but a change of pace was needed to bring out the professionalism of all our collaborators, within this great business plan”, tells us Ira Nicoletti, also the protagonist of a professional growth path which has led her to engage personally also in the associative sphere as contact person for the board of directors and the Education Commission Group of Atif: “with my brother Filippo we realized that it was not enough to invest in technologies and new methods, but rather it was important to better understand what the natural predispositions of our collaborators were. We involved the entire company and so the corporate character emerged, which allowed us to reorganize our structure, assigning people to the most suitable roles based on the characteristics that emerged. This path will have to lead the company to grow at all levels, to become privileged interlocutors also for multinational and not multinational companies that require certain production and quality standards”, adds Ira Nicoletti.

This team effort implemented by Diaven has therefore allowed the Treviso company to improve its internal processes, the relationship between collaborators and with the ownership, which has certainly benefited and contributed to improving the service to the customer, the processes and the internal climate and to get greater consideration also on the market.

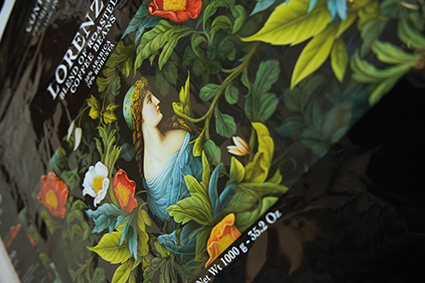

2024 started positively, in the wake of 2023 which ended with the great victory, together with the client Ekaflex, of the 1st prize in the Best In Flexo in the Film wide web inside printing category, a work which also received the Best In Show award, with which companies will participate in the FTA Awards in Dusseldorf, and the award ceremony will take place on May 30th during drupa. In addition to the “Lorenzo” project with Diaven, Ekaflex will participate in the competition with all the works that won the first prize in the 2022/2023 edition of the Best In Flexo.

Ekaflex, a success built with passion and tenacity

Ekaflex is a relatively young company, founded in 2005 by Karim Nardin and Emiliano Besozzi after a few years’ experience which led them to become respectively production manager and print manager at a converting company. Animated by a great entrepreneurial spirit, Karim Nardin and Emiliano Besozzi, in a small space, with a used flexo machine, started the Ekaflex adventure as subcontractors.

“We have a technical background as printers, and for us print quality has always been in first place. The market has always recognized this, even when we were not held in high regard, precisely because we were the latest arrivals. The entrepreneurial spirit that we have never lacked, some youthful mistakes, but also a lot of passion and desire to do well, have led us today, after 18 years of activity, to be a company with 80 employees, 2 flexo gearless central drum machines gearless, 4 laminators, 6 slitter-rewinders, laser die cutter and other special equipment for the production of flexible packaging in plastic film and paper, for all the most varied industrial sectors, with a focus on the food sector”, tells us Karim Nardin, founder and CEO of the company managed today together with the following partners: Emiliano Besozzi, responsible for the lamination and cutting department; Marco Carrara, commercial director, and Cristian Nardin, responsible for the printing department, all with key roles in the strategic points of Ekaflex, supported by Giorgio Branchini, production director.

“We have a technical background as printers, and for us print quality has always been in first place. The market has always recognized this, even when we were not held in high regard, precisely because we were the latest arrivals. The entrepreneurial spirit that we have never lacked, some youthful mistakes, but also a lot of passion and desire to do well, have led us today, after 18 years of activity, to be a company with 80 employees, 2 flexo gearless central drum machines gearless, 4 laminators, 6 slitter-rewinders, laser die cutter and other special equipment for the production of flexible packaging in plastic film and paper, for all the most varied industrial sectors, with a focus on the food sector”, tells us Karim Nardin, founder and CEO of the company managed today together with the following partners: Emiliano Besozzi, responsible for the lamination and cutting department; Marco Carrara, commercial director, and Cristian Nardin, responsible for the printing department, all with key roles in the strategic points of Ekaflex, supported by Giorgio Branchini, production director.

Growth in flexible paper packaging for figurines

A sector in which Ekaflex is very active, developing innovative products, result of internal research and development, is packaging for figurines envelopes where paper naturally finds its application and where the Varese company has carved out a leading role for itself, supplying the key players in the market.

“For Ekaflex, innovation has always been a driving force that has guided us along the growth path, from technologies to materials, always paying attention to market demands”, adds Nardin, “and the openness towards new eco-sustainable materials complicates challenges it but also makes it very fascinating. Until 10 years ago the solution to everything seemed to be compostable materials, so we have carried out studies and research on materials, printability and packaging. Then it became clear that that couldn’t be the only way. Today we are in a moment of great turmoil, and our natural predisposition for experimentation is giving us great satisfaction”, adds Karim Nardin, underlining how thanks to Ekalab, the internal research & development office and thanks to the participation of all the technicians of the company and to dialogue with suppliers and customers, they managed to propose, for example, a lighter material (about 8% less), generating a saving of 5% on the purchase value but above all allowing the customer to increase the packing speed of 15%.

Ekaflex Academy: people at the center

Il covid per l’industria del packaging è stato un periodo di grande lavoro e crescita, ed Ekaflex ha vissuto mesi molto intensi, tanto che avrebbe avuto bisogno di ampliare il proprio organico ma per via delle restrizioni non fu possibile agire tempestivamente. Una crescita di organico che è stata poi portata avanti nel periodo post pandemico, quello che ha visto Ekaflex crescere di circa 30 unità fino all’attuale organico di 80 persone. Anche grazie a quell’esperienza, e con l’obiettivo di crescere ulteriormente, il focus sul personale, elemento strategico per la crescita aziendale, il management di Ekaflex ha dato vita recentemente al progetto “Academy”, iniziativa nata per provare a dare una risposta alle esigenze di reclutamento di nuovi collaboratori.

Covid for the packaging industry was a period of great work and growth, and Ekaflex experienced very intense months, so much so that it would have needed to implement its staff but due to the restrictions it was not possible to act promptly. A growth in staff which was then carried forward in the post-pandemic period, which saw Ekaflex grow by around 30 units up to the current number of 80 people. Also, thanks to that experience, and with the aim of further growing, the focus on personnel, a strategic element for company growth, Ekaflex management recently gave life to the “Academy” project, an initiative created to try to provide an answer to the needs of recruiting new collaborators.

We know how difficult it is to find qualified personnel in the sector, because the only way is taking them away from competitors, an operation that can always hide pitfalls. “With the Academy project which started recently, and which has already achieved enormous success, given that 45 people have signed up, we have started a 12-hour journey with 12 selected people, but we will not leave behind the others who have the time and opportunity to participate, to identify the ideal candidates to include in the workforce. In this moment of comparison and study, we talk about and explain our production process, we share methods, objectives but above all our philosophy”, adds Nardin, enthusiastic about this training project.

Attention to the training sector is one of the strengths that Ekaflex has in common with its supplier of flexo photopolymers Diaven, a characteristic that has undoubtedly contributed to the creation of the winning project at Best In Flexo 2023, the result of competence, technique, passion, where nothing is left to chance and where the human variable is still able to make the difference.

Finally, another fundamental aspect that unites the two realities is the predisposition to listen to the customer and the awareness that service is a fundamental value in the supply of goods as well as the willingness to take on his challenges.