Curiosity is growing around the new patented anilox washing system unveiled by Simec Group that promises an extension of the cylinder lifecycle and performance optimization.

Simec Group launched the first cleaning machine, PROFIL, in 2000. The intent was not to generate an autonomous business unit but to implement a structure devoted (dedicated) to the maintenance of the anilox marketed, with the aim of extending their operating lifetime and maintaining their top performance.

The cleaning systems using baking soda represented an extremely valid solution: ecological, easy to use, effective and without contraindications for the cylinders.

The cleaning systems using baking soda represented an extremely valid solution: ecological, easy to use, effective and without contraindications for the cylinders.

A tool that immediately satisfied and convinced many operators all over the world. For the corrugated cardboard industry, for example, robotic systems have been developed upon request and in partnership with OEMs to obtain cleaning operations extremely simple and automated. In-line systems engineered ad hoc for the tissue converting as well, generated great benefits during maintenance.

Over the years, washing systems based on different technologies have appeared in the market, each of them promising optimal results without any risk.

What is the most effective cleaning system?

Unfortunately, however, the numerous statistical data recorded in the Simec Group’s IRP, collected daily by the incoming inspection on the anilox sent to be refurbished and by the cleaning and maintenance service, clearly indicate that unsuitable washing methods are among the major causes of refurbishment.

Unfortunately, however, the numerous statistical data recorded in the Simec Group’s IRP, collected daily by the incoming inspection on the anilox sent to be refurbished and by the cleaning and maintenance service, clearly indicate that unsuitable washing methods are among the major causes of refurbishment.

Let’s consider the cleaning by laser, for instance. The market offers different types of systems that, due to the characteristics of the laser sources and the optics used, minimize risks. A minimum invasiveness, however, is inevitable and damage to the ceramic layer of the laser engraved rollers can’t be prevented. This is stated by Simec-the-builder-and-engraver-of-rollers, which has been using laser technology to engrave its ceramic anilox since 1987 and has therefore matured a deep knowledge of this instrument, to be able to independently engineer special engraving systems.

It is necessary to adopt cleaning systems that are effective and always safe, during single cycle and after repeated cycles.

A correct cleaning means a longer lifetime of cylinders and a better ink transfer and increase of the printing stability and repetitiveness, a fundamental aspect if you want to get a printing with high screen anilox and low volumetric capacity.

The strategic importance for anilox cleaning

Anilox cleaning should be considered as a strategic lever, instead it is often outsourced or it is carried out inside the factories opting for “easy” systems that imply minimum operator intervention, minimum maintenance and reduced exhausted materials removal problems. When the importance of this aspect of the production activity is instead taken into consideration, the evaluation criteria that lead to the choice of one system rather than another are the maximization of the efficiency/safety ratio, the cleaning frequency imposed by the production needs, the number of rollers to be treated daily and the respective engraving specification. It is also useful to make a choice between the purchase of the cleaning device or the use of an external service, considering the cost of the service and the cost of each cleaning cycle, the time required for treatment, the specialization level needed for the system use.

Anilox cleaning should be considered as a strategic lever, instead it is often outsourced or it is carried out inside the factories opting for “easy” systems that imply minimum operator intervention, minimum maintenance and reduced exhausted materials removal problems. When the importance of this aspect of the production activity is instead taken into consideration, the evaluation criteria that lead to the choice of one system rather than another are the maximization of the efficiency/safety ratio, the cleaning frequency imposed by the production needs, the number of rollers to be treated daily and the respective engraving specification. It is also useful to make a choice between the purchase of the cleaning device or the use of an external service, considering the cost of the service and the cost of each cleaning cycle, the time required for treatment, the specialization level needed for the system use.

Simec Group’s new liquid cleaning system available from June

In the flexible packaging industry, in particular for anilox sleeves, considering the frequency of cleaning cycles needed, it has become necessary to integrate the offer with an operator-friendly system allowing printers to quickly clean their anilox with very low operating costs.

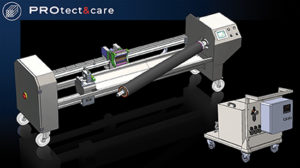

That’s why Simec Group has launched a new liquid cleaning machine entirely engineered in-house. It is a system that not only protects anilox, but also meets all the needs of flexographic printers. It has been tested for a year with different types of inks and screen and its performance has been so astonishing to decide to protect the innovation with an industrial patent.

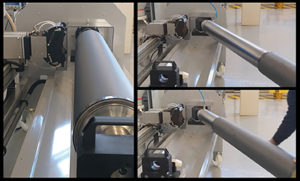

The machine consists of a spraying and recovery unit, a cleaning head and a trolley. It can be used for sleeves of any size thanks to the possibility to vary the length of the pole according to the sleeve size up to 1800 mm and thanks to the adapter carrier which can be purchased directly or from an authorized supplier; the watertight liquid head as well has been designed with rubber seals suitable for different anilox diameters.

The system is provided with rapid change-over: 5 minutes for the pole replacement, 1 minute for the carrier and 1 minute for the rubber seals.

Cleaning has been tested with water and solvent base inks and, depending on the selected washing liquid and trolley model, it works at room temperature or heat up to 40°.

Cleaning has been tested with water and solvent base inks and, depending on the selected washing liquid and trolley model, it works at room temperature or heat up to 40°.

The ordinary cleaning of a 1300 mm sleeve takes 8 minutes, while the deep cleaning takes 16 minutes. For each washing cycle 2.5 liters of product are required; it is a solution consisting of 40% cleanser and 60% water and it is reusable for several cycles.

Thanks to the combination of the mechanical action of the brush with the washing liquid, excellent cleaning is obtained in a short time without any risk for the sleeve.

Series production is starting in June, with the first deliveries of systems already at the end of the same month. Moreover, the production of the brand-new machines has started and they will be destined to different services, applicable first on the whole national territory, then in the other countries where Simec usually operates. The company will propose either the rental of the system which, given its ease of use, does not require a specialized operator and can be managed independently, or the home service or the round-trip cleaning service.

Simec Group has opened its doors to anyone interested in a live demo, which can also be performed on sleeves supplied by the visitor: this is the meaning of “more than engraving”.