CITO Italia Srl is the reliable supplier and contact for products and solutions for efficient diemaking on the Italian market. Diemakers can draw from a wide range of high-quality and innovative CITO brand consumables for cutting dies, stripping and blanking tools.

CITO is one of the leading companies in the field of diecutting technology. It is known and recognised worldwide for its experience, expertise and innovative spirit. In particular, the comprehensive range of ejection material has become a trademark of CITO and sets benchmarks in the industry. The application experts and R&D team work with partners and customers to constantly optimise and enhance the product portfolio. As a result, materials are provided that are specifically tailored to the needs and increasing daily demands and requirement. With CITO being part of BOBST, users also benefit from products where machine, equipment and consumables are matched perfectly.

CITO is one of the leading companies in the field of diecutting technology. It is known and recognised worldwide for its experience, expertise and innovative spirit. In particular, the comprehensive range of ejection material has become a trademark of CITO and sets benchmarks in the industry. The application experts and R&D team work with partners and customers to constantly optimise and enhance the product portfolio. As a result, materials are provided that are specifically tailored to the needs and increasing daily demands and requirement. With CITO being part of BOBST, users also benefit from products where machine, equipment and consumables are matched perfectly.

For this, CITO Italia Srl exclusively offers the following product lines:

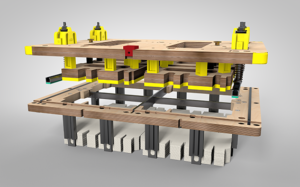

Diecutting: Top-quality ejection material with excellent product properties. The rubber profiles have been specifically designed for diecutting technology, are equipped with self-adhesive CITO EasyFix technology and colour-coding. For safe and efficient processes, higher performance and optimum results.

Stripping: Quality accessories for efficient and reliable dynamic stripping in the diecutter. For safe storage and transport as well as smooth sheet transfer through the machine.

Blanking: Effective components for the upper and lower blanking tool. For easy and economic assembly of the tool, reliable control of the waste, optimum pile guidance and higher machine performance.

CITO Italia Srl offers not only high-quality products for diemaking but also the technical support for optimum application, reliable processes and more efficiency. The CITO GROUP works hand in hand with the product specialists at the headquarters in Germany to provide optimum technical service. The latest offering is individual customised training at diemakers. The companies receive first-hand information by the experts on the product range and the optimum application. Cutting die manufacturers can profit considerably from the training as they can sustainably optimise their processes and build tools that will impress their customers.

CITO Italia Srl offers not only high-quality products for diemaking but also the technical support for optimum application, reliable processes and more efficiency. The CITO GROUP works hand in hand with the product specialists at the headquarters in Germany to provide optimum technical service. The latest offering is individual customised training at diemakers. The companies receive first-hand information by the experts on the product range and the optimum application. Cutting die manufacturers can profit considerably from the training as they can sustainably optimise their processes and build tools that will impress their customers.