Present on the market for almost 60 years, Carta Stampa has always been faithful to the flexographic printing process, so much so that it is one of the first italian companies to have introduced it. Always devoted to process and product innovation, Carta Stampa has been ahead of its time, anticipating market trends, always and in any case with careful and profitable family management. But this may not be enough in the future.

We talk about it with Corbetta family…

The name of this company is already a presentation in itself and contains the essence of the business around which, in 1963, Antonio Corbetta and his wife Rosa Bestetti, who traded in paper, decided to found Carta Stampa, giving life to a reality also specialized in printing in particular flexo, of paper for packaging.

The company has followed the entire technological evolutionary path based on the flexographic printing process, it can be considered one of the pioneers in this sector, following also the evolution of the market and the offer, so much so that over the years the specialization has moved towards flexible packaging, (the company name is still Carta Stampa srl, but “flexible packaging” has been added to the logo).

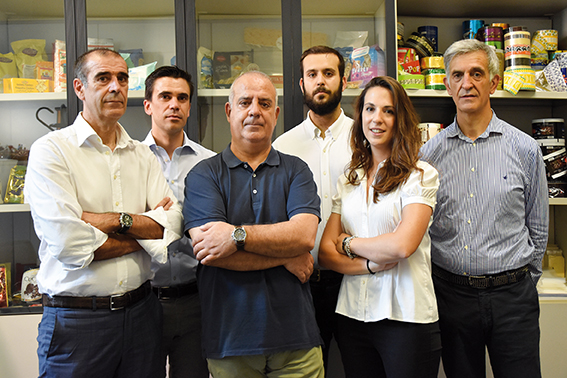

Today the company, which is based in Fornaci di Briosco (MB) employs 55 people and sees the coexistence of the second and third generation, is in an expansion period with the construction of new commercial offices and a new warehouse adjacent to the current production site where print with continuous cycle 3 Uteco flexo printing machines (one 8 colors and two 10 colors), 4 laminators, one of which Triplex, also supplied by Uteco and 4 slitter-rewinders. The company’s equipment also includes 3 mounting machines, one of which is fully automatic, a mixing station for the production of inks starting from the bases, an automatic feeding system on all printing lines for acetate, solvent and white, and finally the dirty solvent recovery system, which after being distilled is used to wash the machines.

Today the company, which is based in Fornaci di Briosco (MB) employs 55 people and sees the coexistence of the second and third generation, is in an expansion period with the construction of new commercial offices and a new warehouse adjacent to the current production site where print with continuous cycle 3 Uteco flexo printing machines (one 8 colors and two 10 colors), 4 laminators, one of which Triplex, also supplied by Uteco and 4 slitter-rewinders. The company’s equipment also includes 3 mounting machines, one of which is fully automatic, a mixing station for the production of inks starting from the bases, an automatic feeding system on all printing lines for acetate, solvent and white, and finally the dirty solvent recovery system, which after being distilled is used to wash the machines.

The brothers Massimo, technical manager, Roberto Corbetta, sales manager, and Antonello, administrative manager, sons of the founders, represent the historical soul of the company and work with their respective children Michela, Riccardo and Luca, the third generation of the family.

The history of packaging, from counter paper to metallized polypropylene film

“Our parents started the business when the packaging was mostly a layer of paper for loose products”, Massimo Corbetta tells us, “printing the sheets of paper that were used in delicatessens, pastry shops but also in pharmacies to wrap the products that customers bought at the counter. It was a rather poor print, the needs were certainly not those of today. With the entry of our children into the company, and also thanks to the evolution of the market, we began to expand our market, with personalized gift paper and finally flexible packaging”, says Massimo.

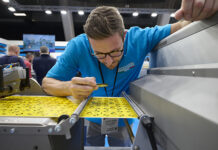

In Carta Stampa they has always looked carefully at technological innovations, which are essential to follow the new market trends. And it is here that the third system for the production of photopolymers in Italy was installed in 1977, before deciding to rely on external suppliers for the production of flexo printing plates. Carta Stampa was also one of the first companies to use engraved rubber rolls, and it was on one of their machines that the printing of a metallized propylene film was realized for the first time.

“I still remember when many suppliers of materials, films and inks told us that we would never be able to print a metallic plastic film with flexo printing, a job traditionally linked to gravure printing”, says Massimo Corbetta, technical manager, “and instead after several attempts, and thanks to our internal research & development, we did it, and a new market has opened up, that of metallized papers for Easter eggs, which was a prelude to our subsequent entry into the flexible packaging sector”.

“I still remember when many suppliers of materials, films and inks told us that we would never be able to print a metallic plastic film with flexo printing, a job traditionally linked to gravure printing”, says Massimo Corbetta, technical manager, “and instead after several attempts, and thanks to our internal research & development, we did it, and a new market has opened up, that of metallized papers for Easter eggs, which was a prelude to our subsequent entry into the flexible packaging sector”.

The advent of digital technology in prepress then allowed Carta Stampa, as well as the entire flexographic sector, to raise the quality level of printed matter, with ever softer shades, a precise and constant ink transfer, getting closer and closer to quality of gravure printing, and being able to guarantee constant and repeatable quality to the market of brand-owners and large-scale distribution even in reprints.

“We serve the entire flexible packaging market, equally divided into various sectors, which allows us to have operational continuity throughout the entire season. We serve the entire Italian market, but we also turn to abroad, especially in North Africa where the offer of high-performance packaging is lacking, with a range of products ranging from single-material to more complex four-layer laminates, although obviously the trend now it pushes more and more towards single-material solutions to favor recycling”, adds Roberto Corbetta.

Research & Development of new products to continue growing with some questions about the future…

Within Carta Stampa there is a very active Research & Development laboratory that is studying high barrier materials through the development of barrier lacquers and glues, all produced internally for some years already, and which recently the new market trends have brought to prominence. “We define ourselves as artisans-industrialists and as such we have the skills and some resources to develop new products and new processes, but obviously we lack the strength and sounding board of a multinational company”, says Roberto, “so we enjoy the satisfaction of having come to find solutions that the market has discovered and used only recently, and of having done so already a few years ago, just like printing on biodegradable, recyclable, compostable materials. In our own small way we have always been forerunners of new trends that the market has then actually followed, we have grown at all levels and the expansion works of our headquarters testify our desire to continue investing and growing.

Within Carta Stampa there is a very active Research & Development laboratory that is studying high barrier materials through the development of barrier lacquers and glues, all produced internally for some years already, and which recently the new market trends have brought to prominence. “We define ourselves as artisans-industrialists and as such we have the skills and some resources to develop new products and new processes, but obviously we lack the strength and sounding board of a multinational company”, says Roberto, “so we enjoy the satisfaction of having come to find solutions that the market has discovered and used only recently, and of having done so already a few years ago, just like printing on biodegradable, recyclable, compostable materials. In our own small way we have always been forerunners of new trends that the market has then actually followed, we have grown at all levels and the expansion works of our headquarters testify our desire to continue investing and growing.

However, we ask ourselves the question of what are the best steps to take for a structure like ours, which has certainly made family management one of its strengths, and which in this moment sees us managing the company together with our children, which have brought impulse and vitality.

We know that to compete on international scenarios this may not be enough in the future, and we are therefore careful and vigilant in evaluating any type of opportunity. We have the ideas, what is unfortunately lacking is a clear vision of the future, above all due to the great uncertainty of the market”, concludes Massimo Corbetta, recalling how shortly before Covid the idea of a stock market listing was probed, one of the possible roads to follow in order to grow and structure at a higher level.

We know that to compete on international scenarios this may not be enough in the future, and we are therefore careful and vigilant in evaluating any type of opportunity. We have the ideas, what is unfortunately lacking is a clear vision of the future, above all due to the great uncertainty of the market”, concludes Massimo Corbetta, recalling how shortly before Covid the idea of a stock market listing was probed, one of the possible roads to follow in order to grow and structure at a higher level.

Waiting for possible future developments, Carta Stampa will continue its investments, and once the new headquarters that will house offices and warehouse are completed, investments in new technologies will also continue.

“With the new building that will be ready in a few months, we aim to adopt a new management system in order to achieve maximum efficiency at all company levels. Industry 4.0 today offers us a unique opportunity to reorganize our processes and structure ourselves to improve competitiveness through the analysis and study of data and we intend to seize this opportunity.

The presence in the company of young people, and we are free to act, allows us to keep up with the times, in a world that runs very fast, in which we want to continue to have our say”, concludes Michela Corbetta who deals with marketing in the company and also participates in the associative life of Atif as a member of the Marketing Commission.