BST eltromat Italia, the subsidiary of BST gmbh, will present five new products for quality assurance in the finishing and processing of all types of flexible and web materials – Print4All Hall 9 Stand H21 K26

The BST CLS CAM 100 is oriented to freely selectable objects and requires neither a supplementary control line nor an additional trigger sensor/signal for precise web guiding. Instead, any object can be defined directly in the print motif as a control criterion. This is done particularly intuitively by touch on the 10-inch touch screen or directly on the sensor.

The BST CLS CAM 100 is oriented to freely selectable objects and requires neither a supplementary control line nor an additional trigger sensor/signal for precise web guiding. Instead, any object can be defined directly in the print motif as a control criterion. This is done particularly intuitively by touch on the 10-inch touch screen or directly on the sensor.

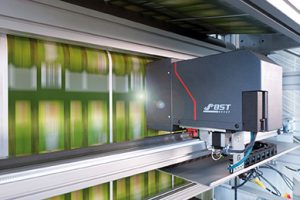

Another highlight that BST will be demonstrating at the trade show is the new BST PROView video web monitoring system. The system, which is suitable for both narrow and wide webs, can be ideally adapted to the needs of users thanks to its modular design. Simplicity was also the focus in the design of BST PROView: from commissioning via plug-n-play, through intuitive operation, to convenient remote maintenance.

Another highlight that BST will be demonstrating at the trade show is the new BST PROView video web monitoring system. The system, which is suitable for both narrow and wide webs, can be ideally adapted to the needs of users thanks to its modular design. Simplicity was also the focus in the design of BST PROView: from commissioning via plug-n-play, through intuitive operation, to convenient remote maintenance.

In addition, BST will present the compact register control system BST TWINStar at the Print4All in Milan. This solution combines the proven and leading BST sensor technology with state-of-the-art, intuitive operation. With its two control points, the BST TWINStar is ideal for hybrid printing and converting presses and offers practical functions such as front-to-back register control. The system can also be conveniently integrated into other press environments via Profinet. “Usability has gained in importance in recent years. Instead of nested menus, the operation of the BST TWINStar therefore follows a One Click – One View philosophy,” says Ingo Ellerbrock (Head of BST product management).

In addition, BST will present the compact register control system BST TWINStar at the Print4All in Milan. This solution combines the proven and leading BST sensor technology with state-of-the-art, intuitive operation. With its two control points, the BST TWINStar is ideal for hybrid printing and converting presses and offers practical functions such as front-to-back register control. The system can also be conveniently integrated into other press environments via Profinet. “Usability has gained in importance in recent years. Instead of nested menus, the operation of the BST TWINStar therefore follows a One Click – One View philosophy,” says Ingo Ellerbrock (Head of BST product management).

All these solutions, which impress with their precision, performance and intuitive operation, are part of the broad BST product portfolio for quality assurance and process optimization.

For an ideal end product and an efficient production process, 100% control of the material web and its surface quality in the finishing process is essential. One more reason why BST is placing a further focus here at Print4All.

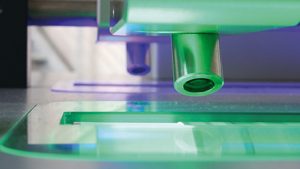

Whether in extrusion, coating, battery cell production or printing machines, for example: Surface inspection only works perfectly if camera, illumination and defect classification are perfectly matched. This is exactly what the latest surface inspection system BST iPQ-Surface does. It is a particularly user-friendly system, as the user can teach the BST solution defect classes, which are then automatically assigned to increasingly better defects. In addition, the BST system is able to interact with the existing network and machine and to fit into the existing IT landscape. As a member of the BST iPQ family, BST iPQ-Surface combines state-of-the-art camera technology with innovative multiplex lighting and makes even the smallest defects visible in a compact installation space. The special feature of a BST iPQ-Surface system is the optimal combination of the individual components. This creates the best solution for individual applications: flexible, modular and, above all, demand-optimized.

Whether in extrusion, coating, battery cell production or printing machines, for example: Surface inspection only works perfectly if camera, illumination and defect classification are perfectly matched. This is exactly what the latest surface inspection system BST iPQ-Surface does. It is a particularly user-friendly system, as the user can teach the BST solution defect classes, which are then automatically assigned to increasingly better defects. In addition, the BST system is able to interact with the existing network and machine and to fit into the existing IT landscape. As a member of the BST iPQ family, BST iPQ-Surface combines state-of-the-art camera technology with innovative multiplex lighting and makes even the smallest defects visible in a compact installation space. The special feature of a BST iPQ-Surface system is the optimal combination of the individual components. This creates the best solution for individual applications: flexible, modular and, above all, demand-optimized.

After the big impact in the market during the last 6 years of the 100% quality inspection system Tubescan Digital Strobe with more than 2000 systems sold around the world in narrow web applications , Nyquist system , a brother company of BST gmbh in the Elexis group, launched in the market the new Tubescan XL , a low cost 100% inspection system for Flexible packaging inspection.

Tubescan XL, suitable for application up to 1700 mm web width, is studied for the quality inspection on the Printing press as well on slitter and doctoring machines and thanks to the Qlink package ensure a complete work flow control.

“Print4all was and is the leading trade show for the converting and printing industry in Italy. We are pleased that the show is finally taking place again after four years and that we can once again bring our products to life here and meet live again our customers”, Paolo Tamburrini, BST eltromat Italia managing director.