On the occasion of Global Flexo Innovation Awards organized by Miraclon this year, IsmaColor, flexo prepress service based in Ostra (AN) won the gold prize at in the following excellence categories: Conversion from other print processes, Creative use of Graphic Design and Print Production Workflow Efficiency. Three cardboard folding boxes were awarded, flexo printed and realized with sustainable materials and very high shelf impact

On the occasion of Global Flexo Innovation Awards organized by Miraclon this year, IsmaColor, flexo prepress service based in Ostra (AN) won the gold prize at in the following excellence categories: Conversion from other print processes, Creative use of Graphic Design and Print Production Workflow Efficiency. Three cardboard folding boxes were awarded, flexo printed and realized with sustainable materials and very high shelf impact

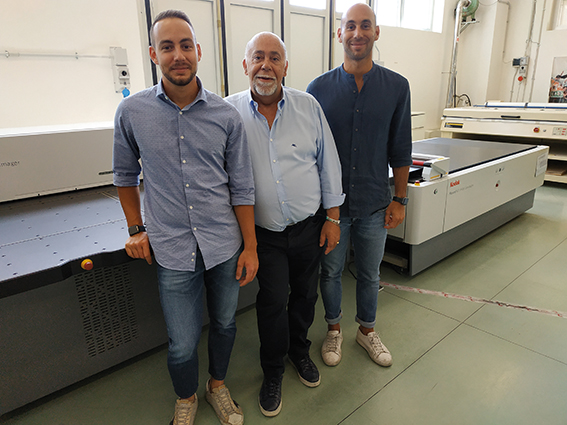

Isma Color was born in 1996, founded by Mario Mancini, now the company has 20 employees, with Mario are working also his two sons, Marco and Andrea. The company operates in the new headquarters of Casine di Ostra, in a modern and efficient factory where beauty combines with functional in in full awareness of the fact that the architecture of the workplace contributes actively to the achievement of high standards of well-being and quality of life, decisive for the success of every activity.

Isma Color offers itself as an external service for operators in the flexographic and offset printing sector, allowing them to outsource the preparation of files and plates needed to print their products. “Outsourcing of a highly specialized process such as prepress ensures the customer several advantages, that is: the guarantee of always having the best technology available on the market, pre-press is in fact our core business and not a complementary process, it is therefore in our interest to stay up to date on the best available to improve product quality, reduce costs and waste; the security of an optimized and efficient process; the reduction of structural costs; high quality guaranteed by skilled operators in color management”, says Mario Mancini.

Surely these are also the critical success factors of the company that in recent years has established itself among the best Italian pre-press services. This is why Isma Color now includes among its customers excellent brands. The market to which the company turns is in fact characterized by an elaborate, refined and attractive product and in which the service, the care and the assistance to the customer, the flexibility in addition to the technology, are crucial to remain among the first in the class.

Surely these are also the critical success factors of the company that in recent years has established itself among the best Italian pre-press services. This is why Isma Color now includes among its customers excellent brands. The market to which the company turns is in fact characterized by an elaborate, refined and attractive product and in which the service, the care and the assistance to the customer, the flexibility in addition to the technology, are crucial to remain among the first in the class.

In this regard, the commitment made by all the company staff has allowed the company to obtain important awards, including the gold medal at the Global Flexo Innovation Awards, an international contest, in these categories of excellence: Conversion from other print processes, Creative use of Graphic Design and Print Production Workflow Efficiency.

The Global Flexo Innovation Awards was established by Miraclon to reward companies that, through innovation, drive the transformation of the flexographic standards industry around the world, in particular using the Kodak Flexcel NX system, cutting-edge technology that allows to obtain numerous advantages in terms of quality and efficiency. Isma Color was a pioneer as regards this technology.

With NX technology the image stands out for brighter and more vivid colors as well as for a greater range of colors available to the printer. This system allows to reach a resolution up to 10,000 optical dpi. In addition to a better image quality, the typical flat dot point of this technology ensures lower ink consumption and longer plate life and reduces machine start-up times with considerable production advantages. For this reason, more and more printers and packaging consumers are moving from offset to flexo technology, convinced by the quality of the product as well as by the advantages in terms of efficiency.

and packaging consumers are moving from offset to flexo technology, convinced by the quality of the product as well as by the advantages in terms of efficiency.

Convincing a company that historically has always worked in a certain way or purchased from the usual suppliers to change its point of view and its purchasing policies is not a rapid process since every change generates uncertainties. It is here that Isma Color technicians intervene who, thanks to their many years of experience in the prepress and flexo printing sector, can support the customer in optimizing their process. This, combined with the flexibility of Isma Color and the reliability of the prepress process, allows to reduce overall costs and time to market.

Perfect synergy between prepress and printing

IsmaColor has grown a lot in these last years, thanks to experience acquired in flexo prepress activity, above all as regards colour management and printing process quality. In 2016, he decided to widen its offer and decided to enter in printing market, with the installation of a super flexo machine: the Gallus CCS 510. With this machine were realized the awarded products, produced entirely in-house in one passage from web to die-cutting.

Folding carton characterized by high printing quality, strong visual impact and sustainability

The box for Emmediciotto – 09 Old Solution (haircare product) was chosen for its shelf visual impact: IsmaColor used an iridescent cold foil film; thanks to the high technology of printing press and to the technicians who fully exploited its potential, productivity was high with reduced costs and high level quality of the finished product. The Mascalzone Latino box (shaving products) is a perfect example of the most successful conversion from offset to flexo printing. Without doubt the use of Kodak Flexcel NX assured an amazing image resolution with a quality equal to offset.

The box for Emmediciotto – 09 Old Solution (haircare product) was chosen for its shelf visual impact: IsmaColor used an iridescent cold foil film; thanks to the high technology of printing press and to the technicians who fully exploited its potential, productivity was high with reduced costs and high level quality of the finished product. The Mascalzone Latino box (shaving products) is a perfect example of the most successful conversion from offset to flexo printing. Without doubt the use of Kodak Flexcel NX assured an amazing image resolution with a quality equal to offset.

For the sample Vitamina D (brand Frau) it has been used Chromocard 300gr FSC paper. The FSC paper is purchased from certified local paper mills managed responsibly, bringing not only environmental benefits but also social and economic benefits.