Two years after the event organized by ZDue at Ferrari Museum, which focused on launching new technologies for flexographic photopolymer production, the Castelfranco Emilia (MO) prepress service is taking concrete action on sustainability and cost savings for printers and converters. We discuss this in an interview with Marco Mingozzi, who is also featured in a video

Innovation has always been in ZDue’s DNA, a historic flexographic prepress service from Emilia with strong expertise in corrugated cardboard. Just over two years after the big event at Ferrari Museum, which introduced new screening technologies based on algorithms. now widely adopted in the market, ZDue is back in the spotlight with a new sustainable strategy. This approach not only meets internal needs but also supports printers and converters in a process of efficiency and optimization based on measurable data. Sustainability is often discussed in theoretical terms, but in this case, there are tangible elements where sustainability is backed by practical actions. Additionally, cost savings for printers and converters are a direct result of the certification process offered by the Italian service.

“We have embarked on a journey toward optimizing resources and processes”, says Marco Mingozzi, emphasizing the importance of data measurement and analysis to demonstrate the effectiveness of these solutions to customers.

This journey, initiated with the introduction of Vortex and BlueEdge, has opened new opportunities. Over the following two years, ZDue developed a new project, investing significant resources to complete a dual strategic path: one focused on product evolution and the other on sustainability certifications for these products. As a result, today, all flexographic photopolymers, regardless of sector or application, are ISO/TS 14067 certified, with the exact carbon footprint calculation and verified by an external certification body.

Three new product families, all ISO 14067 certified

The key step taken by ZDue’s management, which seamlessly integrates the first and second generations of Mingozzi family, was the reorganization of all products into three new families, available from January 2025. These replace all previous products across all thicknesses as follows:

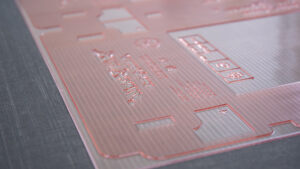

– Zero (No Pollution Plate) – A new type of photopolymer dedicated to printing on high-absorbency corrugated cardboard. Produced without solvents and with complete waste recovery, it resembles liquid photopolymer but differs in its manufacturing process and raw materials.

– BlueLine – It includes the entire range of ZDue’s conventional photopolymers, now with controlled CO₂ emissions.

– TIC System (Total Ink Control) – It encompasses all solutions developed using algorithms previously introduced in the Italian market by ZDue. These solutions now certify a significant reduction in CO₂ emissions during the printing process.

“In the past two years, we have worked on two parallel tracks, particularly with the Zero photopolymer and the TIC System, to enhance the characteristics and performance of existing products and to give them a more sustainable direction. The result is a plate (ZERO) that produces about 50% less CO₂ than solvent-based plates and a system (TIC, an acronym for Total Ink Control) that transforms the Vortex and BlueEdge algorithms, offering customized solutions for every type of substrate, machine, anilox, and ink. This high flexibility allows printers to optimize the process and consequently reduce CO₂ emissions during printing”, says Marco Mingozzi.

The journey to achieve this result was long and demanding, involving significant investments in IT, software, data analysis, research, and data integration to accurately measure CO₂ emissions.

New protocol for CO₂ reduction in printing : up to 30%

“For companies preparing sustainability reports, and we have many printers as well as brand owners who require them, this 1.5% CO₂ reduction is still significant”, says Marco. “However, we didn’t want to stop there. We raised the bar by creating an ISO 14021-certified protocol that allows us to make an assertion for each client’s printing process according to the application, considering their specific printing conditions. Analyzing the printing process, the CO₂ savings achieved with the TIC System compared to conventional technologies is substantial and can reach up to 30%, which is highly beneficial for brand owners and big printers, companies already preparing sustainability reports and highly interested in meeting the 2026 ESG deadline. Smaller companies will also be involved later”, adds Mingozzi. To reinforce its marketing efforts, ZDue will participate as an exhibitor at Print4All, where it will present new product lines and certified CO₂ reduction protocols with a particular focus on corrugated cardboard printing.

The keyword is saving!

ZDue’s focus on sustainability is not new, the company has been addressing this issue since 2016, long before it became a widely debated topic. Various initiatives have aimed at reducing environmental impact, primarily through technological investments, such as an afterburner, a solvent recovery plant, solar panels, and digitalization of processes.

Additionally, as regards ESG, ZDue began publishing a sustainability report in 2023 through Synesgy, starting at Level C. In its latest annual update in 2024, the company advanced to Level B, certifying a strong sustainability standard in line with national and international best practices.

“All this requires investment and great effort. We had to train staff to follow these protocols, positioning us in a mid-to-high market segment. However, as the saying goes, ‘spend more, save more’, the initial investment in a slightly more expensive system can, in the long run, be completely offset by a more efficient and optimized process, minimizing machine downtime, reducing ink and water consumption in cleaning cycles, and optimizing other printing variables that, if left unmeasured, remain vague”, adds Marco Mingozzi.

He emphasizes that a protocol like this, which combines sustainability and cost savings, is a game-changer in today’s market and is the foundation of ZDue’s new path of innovation.