Fresh from a highly successful participation in Labelexpo Europe, which showed all the technological potential of the Japanese multinational for the label sector, SCREEN Europe inaugurated the new headquarters in The Netherlands and the Inkjet Innovation Center, a place where the company can show customers all digital printing technologies for commercial, labels and paper packaging sectors, but above all flexible packaging, launching a real challenge to the market

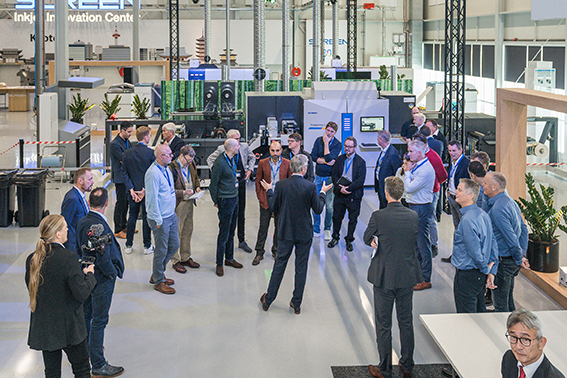

2023 was a very important year for the strategy of SCREEN Europe which celebrated 80 years in the printing sector by exhibiting for the first time a flexible paper packaging machine in its stand at the latest edition of Labelexpo Europe, clearly presenting the latest innovations in web inkjet printing for the label sector and inaugurating, with a ceremony open to some selected European partners, the new headquarters in Aalsmeer in The Netherlands with 5,400 square meters of space with modern and sustainable offices. Inside the new factory has been planned the beautiful Inkjet Innovation Center: 2,000 square meters of showroom where all SCREEN technologies are installed and where future innovations will also find space. SCREEN is active leader in the industrial semiconductor sector which represents the core business, but the graphic arts industry is the second most important department and above all the one identified by the management where to invest in the long term to grow and have an impact on a technological level with the most innovative inkjet solutions available today for all application sectors.

“As well as showcasing our range of digital printers, the Inkjet Innovation Center will act as a hub for innovations in this sector. Working closely with our software and finishing partners, our goal is to provide customers with end-to-end printing solutions, offering a glimpse into the future of the printing industry”, said Osamu Yamagata, President of SCREEN Europe.

SCREEN management in full force with Mr. Osamu Yamagata, President of SCREEN Europe, Mr. Eiji Kakiuchi, President SCREEN Holding Group, Bui Burke, Senior Vice President Sales of SCREEN Europe, Carlo Sammarco, Business Development Director Packaging Solutions SCREEN Europe and Juan Cano, Director of Marketing and Business Development Director of SCREEN Europe with whom we explored the company’s development and penetration strategy in the flexible packaging market, a real challenge that the Group has just launched to the market.

Truepress JET, Truepress Label and Truepress PAC: three product lines for the world of inkjet printing

Today the SCREEN range is made up of three lines of printing machines dedicated to the commercial, labels and packaging sectors. In the commercial sector, now more than consolidated, the Truepress JET range is the natural evolution of a journey that began in 2000 with hybrid offset-digital technologies which represented the natural transition towards the presentation in 2006 of the first developed Truepresses up to the present day and which we find available in the various models of the 520 series for printing books on demand and various commercial web applications. A sector which after Covid saw many productions return from the Far East, reopening consequently market spaces that seemed to have been lost.

Carlo Sammarco, after a Labelexpo 2023 full of satisfaction, retraced the evolution of the label machines presented for the first time at Labelexpo 2013 and today particularly appreciated, especially the Truepress LABEL 350UV SAI model. This model has achieved great success in Italy also thanks to the excellent work carried out by REM – Ettore Maretti is the manager and sales director of this company – who represents SCREEN in our territory, also receiving several awards as the best SCREEN distributor worldwide.

As for the news, the last one is the collaboration with Nilpeter which supplied the FA line module, integrated with the Truepress LABEL, to create a complete printing and finishing line in a single step.

As for the news, the last one is the collaboration with Nilpeter which supplied the FA line module, integrated with the Truepress LABEL, to create a complete printing and finishing line in a single step.

Finally, the latest addition: the machine that will represent the flagship for the future of digital flexible packaging for SCREEN’s strategy. We are talking about the Truepress PAC 520P, a digital printing machine with water-based inks, already active in the world of paper-based packaging solutions and now also ready for the flexible packaging sector, again with water-based inks and sure for food packaging.

Face-to-face with Juan Cano, Director of Marketing and Business Development Director at SCREEN Europe

Juan, what is the state of the art regarding digital printing of flexible packaging today?

“To date, the market for flexible packaging printed with digital technologies is worth around 1% of the total, so do you understand how much we have to conquer? At the moment the technologies on the market for this sector are mainly low-speed solutions (20 meters per minute), with toner inks, used for short runs, mock-ups or customized campaigns. In the paper-based flexible packaging sector we are already present with our Truepress PAC 520P, a compact equipment, present in the new showroom, ideal for those applications that can switch from plastic to paper, such as for example dry food but also non-food packaging. This digital printing machine allows you to create paper-based packaging printed using water-based inks on uncoated paper from 45 to 250 g/sm, at a speed, depending on the configuration and applications, of 80 meters per minute at a CMYK resolution of 600×900 dpi”.

Can you tell us about the challenge you are launching to the market with the new Truepress PAC 830F for flexible plastic packaging?

“I joined SCREEN precisely to carry forward this very ambitious and highly challenging project, for us, but also for the market. There are interested companies, I am thinking of label producers who want to face new challenges, but also big converters who have the ability to guide and manage new trends. It is clear that we are talking about a very important investment and at the moment not within everyone’s reach, but we think that in the future, when this solution will be present on the market on a larger scale, the costs will be more competitive. The Truepress PAC 830F, which we will soon install in the demo center in The Netherlands, is an important technology, starting from its dimensions. The line is made up of an unwinder, a primer unit, a four-colour printing engine + a digital ink jet white, a drying unit, a quality inspection and the final rewinding. The future, we are certain, will be digital inkjet also in the world of flexible plastic packaging and we are ready to do our part to create valuable solutions. Soon a Truepress PAC 830F model will be installed right in the Innovation Center and will be available for demos and tests for customers and prospects interested in deepening their knowledge of digital printing in flexible packaging applications, as well as obviously all the SCREEN machines available for commercial and publishing applications and for labels”.

How do you think the Italian market might respond to this innovation? With REM, your Italian dealer, what actions do you plan to take. Have you already identified the identikit of target companies?

“Italy is the second largest producer of flexible packaging, after Germany, and therefore this is a market of strategic importance for our new range of Truepress PAC digital inkjet presses aimed at both paper-based packaging and plastic films. The Italian flexible packaging market is undergoing a transformation to respond to consumer demand for more sustainable and recyclable packaging. We have already seen great interest in our two new digital presses, both from traditional converters and label companies in Italy, who want to understand the sustainability benefits of digital printing and its overall positive impact on the life cycle analysis (LCA) for each specific type of packaging. Given the enormous success that REM, our local distributor in Italy, has achieved in recent years in promoting our range of Truepress LABEL digital presses, it was natural to extend our collaboration with Ettore Maretti and his team, for the promotion of our new Truepress PAC range in the flexible packaging market. Initially, we expect more progress with our Truepress PAC 520P digital press for paper packaging since the demand for this eco-friendly substrate in Italy is growing rapidly and we already have a demo unit of this type available for customer trials in our recently inaugurated Inkjet Innovation Center in The Netherlands. We are also excited to showcase the industrial production capabilities of our much larger Truepress PAC830F for plastic films for converters who really want to take digitally printed flexible packaging to the next level”.

The opinion of Hery-Christian Henry, packaging and sustainability expert

Speaking at the end of the inauguration of SCREEN Europe’s Inkjet Innovation Centre, Hery-Christian Henry, an expert in packaging and sustainability, gave a very interesting speech about the essential strategies to address sustainability with a strategic vision, reaching the conclusion that from his point of view, the future of printing “can only be digital, even in the world of flexible packaging, capable of incorporating all the main megatrends that actually favor it in consumer choice: traceability of the supply chain, print-on -demand and web-to-print, extreme customization and last but not least the sustainability of the process”.