From 6 to 10 June Simonazzi organized an open house at its headquarters in Pessano con Bornago (Mi) to present its range of products and technologies for narrow web printing. An informal event that saw the participation of 25 label manufacturers who had the opportunity to attend live demos of the latest news from the companies represented by Simonazzi for the Italian market

The label sector is in great expansion and the void left by Labelexpo move has prompted Simonazzi to organize an open house at its headquarters in Pessano con Bornago, near Milan, to present the range of products and technologies dedicated to printing labels. Simonazzi is in fact a reseller for the Italian market of 11 multinational companies, leaders in their respective sectors, and thanks to qualified technicians, offers a pre and post sales consultancy service, the flagship of this small but dynamic family-run business that sees Luciana and Manuela Simonazzi carry on the company founded by their father.

“The label market for us is interesting not so much as regards the square meters of polymer, as for a series of very interesting components for the printing press and auxiliary equipment”, begins Enrico Albani Sales & Marketing Director of Simonazzi.

Focus on the new laser system for cleaning narrow web anilox SITEXCO LABEL L10

From the Spanish company Teg Technologies, the new laser system for cleaning narrow web anilox was the element that most attracted the interest of visitors. We are talking about an extremely compact machine, which can be placed on a table and moved according to the customer’s needs, without the need for installation, extremely easy to use.

TTG, which offers technological solutions for the laser cleaning of medium and wide web anilox, now with L10 also enters the label sector with a system with an excellent price/performance ratio, which for obvious reasons cannot be inserted inside a workflow 4.0, but which uses the same type of laser as the systems for the widest web. The cleaning cycle of an anilox with a maximum width of 530 mm is guaranteed in 7/8 minutes.

“To offer quality flexo printing it is essential to ensure ink transfer and this is possible if the anilox installed in the printing machine is able to guarantee optimal performance, so it must be kept clean. I know the topic is extremely thorny, but many times we see anilox re-made that instead would just need a deep cleaning. The LABEL 10 laser must be set up and managed in the cleaning cycles at low power. Our laser systems offer three cleaning cycles from 7 to 25 minutes maximum and without increasing the laser power”, adds Enrico Albani.

An important feature of this system is the reduced maintenance, we are talking about two filters that must be replaced every couple of years. In addition, the laser beam from above avoids the deposit of ashes, and only occasionally is it necessary to clean the optical systems. The ashes collected in the filters are similar to an urban solid residue and do not require specific disposal, avoiding further costs and bureaucratic procedures.

An important feature of this system is the reduced maintenance, we are talking about two filters that must be replaced every couple of years. In addition, the laser beam from above avoids the deposit of ashes, and only occasionally is it necessary to clean the optical systems. The ashes collected in the filters are similar to an urban solid residue and do not require specific disposal, avoiding further costs and bureaucratic procedures.

“The label manufacturers who saw it in operation were favorably impressed and we decided, considered the compact size of the plant, to physically take it to the various customers who could see and test it”, tells us Enrico Albani, confirming that for Simonazzi the laser is the future of anilox cleaning.

The most advanced laser models for the label sector (mod SNP 1.0) are certified for industry 4.0, they can be connected to the company management system, allowing a precise classification of each individual anilox and configuring the system so that each anilox is always clean with the same program, with a daily or weekly cleaning report, and effectively becoming a measurable cost center.

The other solutions for the label world: plate mounting systems, anilox and sleeves of the latest generation

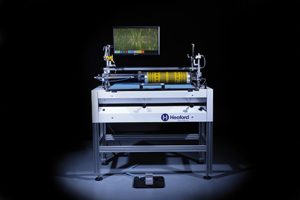

As for the assembly of the clichés, Simonazzi offers the technologies of the English company JM Heaford, which for flexible packaging offers a practically automatic system, where the only action that the operator must perform is to place the plate on the two cameras, which in turn, reading the register marks, will position themselves in register to begin the assembly process. “In the case of the label model that is proposed in the 500, 600 and 700 format, we are in the presence of semi-automatic technology, which only requires framing on the horizontal line of the screen of register mark and that’s it. We have customers who with one plate mounting system serve easily three printing machines”, adds Albani, recalling that in a sector such as label printing where there are several daily job changes, the speed factor is very important.

As for the assembly of the clichés, Simonazzi offers the technologies of the English company JM Heaford, which for flexible packaging offers a practically automatic system, where the only action that the operator must perform is to place the plate on the two cameras, which in turn, reading the register marks, will position themselves in register to begin the assembly process. “In the case of the label model that is proposed in the 500, 600 and 700 format, we are in the presence of semi-automatic technology, which only requires framing on the horizontal line of the screen of register mark and that’s it. We have customers who with one plate mounting system serve easily three printing machines”, adds Albani, recalling that in a sector such as label printing where there are several daily job changes, the speed factor is very important.

Another product that represents a workhorse for Simonazzi are the sleeves, serving practically all the main manufacturers of narrow web printing machines, to which is also added a good share of printers who use the sleeves to print labels and who use the products of Axcyl-Trelleborg, a Swedish company chosen by Simonazzi for this important component of the printing machines. “Our offer is characterized by all products of the highest quality. In the case of sleeves, given the great importance they have in the printing process, quality is the precondition, then certainly the price is important, but it is not the first discriminating factor. The fact is that if I tell the customer that with our sleeves the printing machine can run at maximum speed without any kind of bounce, and we are able to demonstrate with facts what we promise, the price will always take a back seat”, concludes Enrico Albani.

Another product that represents a workhorse for Simonazzi are the sleeves, serving practically all the main manufacturers of narrow web printing machines, to which is also added a good share of printers who use the sleeves to print labels and who use the products of Axcyl-Trelleborg, a Swedish company chosen by Simonazzi for this important component of the printing machines. “Our offer is characterized by all products of the highest quality. In the case of sleeves, given the great importance they have in the printing process, quality is the precondition, then certainly the price is important, but it is not the first discriminating factor. The fact is that if I tell the customer that with our sleeves the printing machine can run at maximum speed without any kind of bounce, and we are able to demonstrate with facts what we promise, the price will always take a back seat”, concludes Enrico Albani.

For Simonazzi this was the first open house dedicated to the world of labels, the experiment was certainly positive and the customer feedback received will push the specialist flexo printing retailer to plan other events in the future, with focuses on other sectors and technologies so as to cover the entire range of products offered.