In a sector where the big players in the market do not always get involved, Expert Srl of San Martino Buon Albergo (Verona) offers a Model of Gearless Flexographic Printing Stack Press with characteristics of stability, accuracy of register and great ease of use, intended for various sectors, including paper, plastic, packaging and converting in general.

In a sector where the big players in the market do not always get involved, Expert Srl of San Martino Buon Albergo (Verona) offers a Model of Gearless Flexographic Printing Stack Press with characteristics of stability, accuracy of register and great ease of use, intended for various sectors, including paper, plastic, packaging and converting in general.

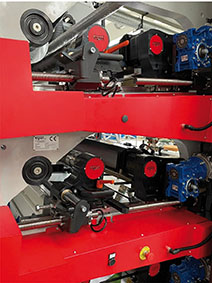

The machine has large windows and large spaces for the preparation of the work and for the cleaning as normal service. The printing unit slides on linear guides, and the large ball screws work in traction, helping to compact the printing unit in work, for greater stability.

The motorization of the cliché axis is a Direct Drive, and ensures excellent register control.

In the version in-line to extruders, the counter-print cylinder is supplied in the configuration with mandrel and counter-print sleeve, so that the side diameter reductions compensate for the extra thickness of the side tube gussets. A superior model is proposed with separate color group windows and all the security systems that allow the preparation of inactive print groups while printing, without stopping the work in progress.

The access for cleaning the intercolor drying units is double: from the front through the hinged opening of the stainless-steel blowers, and from the back through the flipping of the counterpart panels, ensuring excellent access to the whole area.

The inking system is by closed chamber blades holder, designed by Expert for savings in the use of inks and solvents, but the roller inking system is also proposed, for the economy in re-engraving of anilox and in the use of consumable accessories.

The inking system is by closed chamber blades holder, designed by Expert for savings in the use of inks and solvents, but the roller inking system is also proposed, for the economy in re-engraving of anilox and in the use of consumable accessories.

The digital touch screen interface and the combination of PLC and service PC guarantee integration with the Industry 4.0 system and the connection with the company’s IT system.