IST has a thirty-year history in the design and construction of systems for the distillation of solvents and machinery for the automatic cleaning of printing components. At Labelexpo, it will present its solutions for the world of labels.

IST has a thirty-year history in the design and construction of systems for the distillation of solvents and machinery for the automatic cleaning of printing components. At Labelexpo, it will present its solutions for the world of labels.

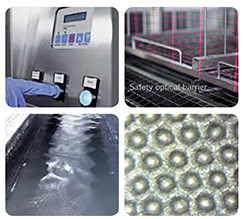

Distilling the solvent is a process that turns out to be economical, as a distilled liter costs a few cents of €, safe and ecological; through the technologies proposed by IST the process takes place automatically. The separation of substances by distillation exploits the different boiling temperatures of the same. It is a totally physical process that does not change the chemical characteristics of the products. Thanks to the distillation, the pure fraction of the solvent is separated from the dirt that remains in the distiller.

As far as washing solutions are concerned, IST offers two different technologies, spray or ultrasonic washing units.

As far as washing solutions are concerned, IST offers two different technologies, spray or ultrasonic washing units.

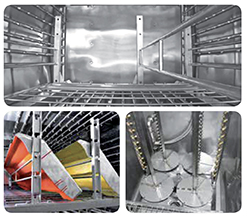

In the spray washing units, after loading the pieces, the washing liquid is taken from the tank inside the machine and, thanks to a pump, made to circulate through different type nozzles, going to strike with force and surfaces. The mechanical action of the jet, combined with the chemical action of the product, removes dirt regenerating the contaminated pieces. At the end of the cycle, the liquid is again collected in the internal tank and the pieces can be extracted. The washing product can be sent to a specific treatment system to be reused, minimizing operating costs.

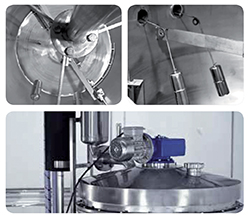

In cleaning systems with ultrasonic washing units, the operation is based on the generation of high frequency waves (vibration) inside a tank containing water and detergent. The oscillating power supplied by the generator is transferred from the sonotrodes to the washing liquid in which, by means of a strong alternating pressure, microscopic bubbles are created which disintegrate the dirt. Ultrasonic propagation creates a cleaning action at the molecular level and eliminates the operator’s exposure to potentially dangerous chemicals.

In cleaning systems with ultrasonic washing units, the operation is based on the generation of high frequency waves (vibration) inside a tank containing water and detergent. The oscillating power supplied by the generator is transferred from the sonotrodes to the washing liquid in which, by means of a strong alternating pressure, microscopic bubbles are created which disintegrate the dirt. Ultrasonic propagation creates a cleaning action at the molecular level and eliminates the operator’s exposure to potentially dangerous chemicals.