All current E+L components are ‘IoT 4.0-ready,’ i.e. suitable for integration into the latest generation of production systems. Each of the devices manufactured in large numbers, whether it is a sensor, a web guider or a high-precision linear drive, can be connected both actively and passively to digital networks. E+L technology therefore integrates perfectly into the production and/or ERP systems of the users to make automated and documented manufacture possible. ELSCAN OMS6 is a video system for operating widths of up to 3,250 mm that meets very high demands on the image quality. It features a large field of view of 234 x 124 mm and an LED flash and can be optionally equipped with a varnish flash, UV flash and different rear flashes. The camera navigation is of high precision and extremely dynamic.

All current E+L components are ‘IoT 4.0-ready,’ i.e. suitable for integration into the latest generation of production systems. Each of the devices manufactured in large numbers, whether it is a sensor, a web guider or a high-precision linear drive, can be connected both actively and passively to digital networks. E+L technology therefore integrates perfectly into the production and/or ERP systems of the users to make automated and documented manufacture possible. ELSCAN OMS6 is a video system for operating widths of up to 3,250 mm that meets very high demands on the image quality. It features a large field of view of 234 x 124 mm and an LED flash and can be optionally equipped with a varnish flash, UV flash and different rear flashes. The camera navigation is of high precision and extremely dynamic. All web monitoring systems use the dualView technology patented by E+L, i.e. two cameras with fixed focal lengths, which are combined in a shared housing: one camera shows a large repeat area (wide-angle lens), while the other camera shows the smallest details (telephoto lens). The section of the image from the telephoto camera is in the center of the wide angle camera. During digital zooming, the camera switches imperceptibly between the two cameras to enable your print image to be displayed with amultiple of the print resolution. This special technology allows high-resolution images of different repeat sections to be displayed without a time delay. ELTIM allows for the contactless measurement of layer thickness, weight per unit area and other material properties across the entire web width, in this way enabling complete quality assurance for a wide variety of films and composite materials. The measurement is done using ultrasound, without the need for complex system calibration. The measuring accuracy is up to 0.5 % of the measured value.The AG 9 is the first actuating drive developed

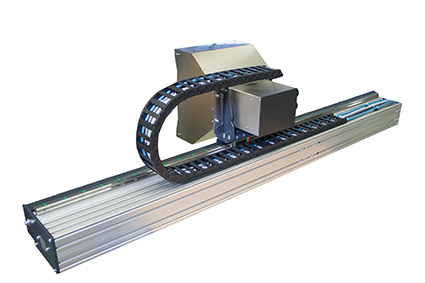

All web monitoring systems use the dualView technology patented by E+L, i.e. two cameras with fixed focal lengths, which are combined in a shared housing: one camera shows a large repeat area (wide-angle lens), while the other camera shows the smallest details (telephoto lens). The section of the image from the telephoto camera is in the center of the wide angle camera. During digital zooming, the camera switches imperceptibly between the two cameras to enable your print image to be displayed with amultiple of the print resolution. This special technology allows high-resolution images of different repeat sections to be displayed without a time delay. ELTIM allows for the contactless measurement of layer thickness, weight per unit area and other material properties across the entire web width, in this way enabling complete quality assurance for a wide variety of films and composite materials. The measurement is done using ultrasound, without the need for complex system calibration. The measuring accuracy is up to 0.5 % of the measured value.The AG 9 is the first actuating drive developed entirely by E+L. The device was primarily designed for web guiding systems, however in principle it can be used in all applications that require a maintenance-free, highly dynamic linear drive with a large actuating force. In combination with the command station DO 3001 or DO 33, the AG 9 is used for web guiding on unwinders, winders and in large pivoting frames. The AG 9 is the only fully integrated actuating drive on the market with a brushless and therefore wear-free motor. The position is acquired via an integrated absolute encoder – this is also a unique feature. As the AG 9 is a direct drive without gearbox, it is almost play-free in the axial direction. The device itself is highly compact, allowing it to be mounted even in tight spaces.

entirely by E+L. The device was primarily designed for web guiding systems, however in principle it can be used in all applications that require a maintenance-free, highly dynamic linear drive with a large actuating force. In combination with the command station DO 3001 or DO 33, the AG 9 is used for web guiding on unwinders, winders and in large pivoting frames. The AG 9 is the only fully integrated actuating drive on the market with a brushless and therefore wear-free motor. The position is acquired via an integrated absolute encoder – this is also a unique feature. As the AG 9 is a direct drive without gearbox, it is almost play-free in the axial direction. The device itself is highly compact, allowing it to be mounted even in tight spaces.