In order to minimize the physical effort of the employees during the packaging process, Box Marche has invested twelve years ago in an Ergosa C Universal Packer and Virtuo Automatic Packer by Canadian supplier Impack. But of course, there were also economic reasons. In 2019, the renowned Italian packaging manufacturer replaced Virtuo with a latest generation machine.

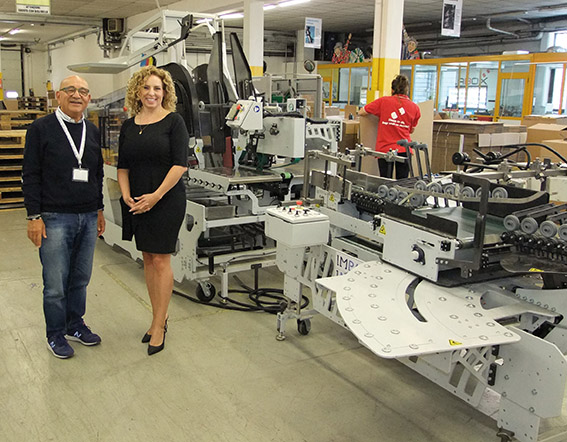

“With our actions and our packaging solutions we want to create values for our environment”, Tonino Dominici begins. In a personal conversation, the CEO and owner of Box Marche S.P.A., Tonino almost seems like a family man. In fact, he sees the company, founded in 1969 and headquartered in Corinaldo (An), in central-eastern Italy, as the center of a community that does not deal only with its own well-being. The packaging manufacturer is quite well known for his social commitment in the province of Ancona and neighboring provinces of Pesaro and Urbino in Marche. At Box Marche, well-being of its employees and close collaboration with customers and suppliers are not just words.

Reducing employee workload and increasing productivity

“Our employees should be able to work without stress and with less physical effort possible. This was one of the main reasons why we installed in 2008 an Ergosa C Universal Packer and a Virtuo Automatic Packer, both supplied by Impack, each behind our two folder-gluers”, says Dominici. Since the two machines were commissioned, no one at Box Marche has had to lift heavy stacks of boxes. “We also make much better use of the productivity of our folder-gluer lines”.

Packing is no longer the bottleneck. That’s why folder-gluers can run faster and employees produce more boxes in the same timeframe with less effort. “A win-win investment”, says the entrepreneur.

While saying this, Dominici takes out of a closet model of sleeves for pan in different sizes, which Box Marche produces mainly for customers located in the region.

The digitally printed cardboard blanks are die-cut in such a way that two circles are joined together with narrower bands. These cardboard circles protect bottom of the pans and the surface coating during transport and in retail outlets. Sleeves are glued on the folder-gluers, and collected at the end of the line with the Ergosa C Universal Packer.

Sleeves are not a problem for Ergosa

“Probably no other packaging system is capable of handling such packaging”, the entrepreneur praises the versatility of the system considering it very flexible. The Ergosa C Universal Packer, compatible with all folder-gluer machines, was developed by Impack for the packaging of small and medium-sized straight line boxes in flat and corrugated cardboard. Most customers use it for straight line and 4/6 corners boxes. Box Marche also processes special formats such sleeves for cooking tools. The company has opted for the Ergosa C model, which combines semi-automatic and automatic packaging. It is equipped with an IN2 Box Turner for turning the products that come out of the folder-gluer at 90°.

“Probably no other packaging system is capable of handling such packaging”, the entrepreneur praises the versatility of the system considering it very flexible. The Ergosa C Universal Packer, compatible with all folder-gluer machines, was developed by Impack for the packaging of small and medium-sized straight line boxes in flat and corrugated cardboard. Most customers use it for straight line and 4/6 corners boxes. Box Marche also processes special formats such sleeves for cooking tools. The company has opted for the Ergosa C model, which combines semi-automatic and automatic packaging. It is equipped with an IN2 Box Turner for turning the products that come out of the folder-gluer at 90°.

In this way, the glue point on the protective wraps is turned upwards when each row is removed from the Ergosa C conveyor and placed in the box. With the glue points on the top, the stacks are more stable and the operators can insert them more easily into the cases. If the packaging products do not need to be turned, they simply go through the Box Turner.

Up to 30 stress-free job changes per day

The very short set-up times are also a point in favour of the Ergosa C. “The medium run of sleeves is 1,000 pieces. We change the machine configuration up to fifteen times per shift”, says Dominici, stressing the need for a quick job change. With Ergosa C, it takes almost nothing to change the format.” Our setup time with this packing machine is practically nil. It is very easy to use and works effectively. In addition, it offers excellent value for money. Moreover, the machine has been running for over eleven years without interruption”, adds the entrepreneur praising the reliability of Ergosa C Universal Packer.

At Box Marche is installed the basic system, which is used exclusively in horizontal mode.

The boxes “slide” from the folder-gluer directly into the Ergosa C, where they are placed by operator in a case positioned to the left of the conveyor. Then these cases are automatically closed and carried away. All this happens without any stress. Because the cases are located lower down in the Ergosa C, packers do not need to lift each row – they can simply slide it into the cases. It is surprising to see how simple and fluid the packaging process can be.

In the event that customers would have new needs, the company could at any time expand its line with additional modules. The Pick & Place mode, for example, would give it great flexibility when packing small series of complex boxes.

Huge relief for employees when packing wine boxes.

Another specialty of Box Marche is the high-quality bag-in-box packaging for wines, which the company produces in laminated micro-flute. These straight line boxes are folded and glued on the line that ends in the Virtuo Automatic Packer.

Another specialty of Box Marche is the high-quality bag-in-box packaging for wines, which the company produces in laminated micro-flute. These straight line boxes are folded and glued on the line that ends in the Virtuo Automatic Packer.

This compact machine has been designed by Impack for medium and large sized boxes in flat and corrugated cardboard. Like Ergosa C, the Virtuo Automatic Packer is characterized by its ease of use and versatility. Above all, however, it significantly alleviates the burden for employees of Box Marche who do not have to fill the cases with the heavy rows of these corrugated cardboard boxes. With the Virtuo Automatic Packer, Box Marche also benefits from the short set-up times of the line, which is changed up to five times per shift.

In early 2019, the Virtuo was updated with the latest model. “The new system works around 10% faster than the previous version. With it, we now pack up to 30,000 bag-in-boxes per hour”, explains Dominici. This also allows also to increase the speed of our folder-gluer. For example, the sophisticated handling of the cases helps to increase the productivity of the new system. The same applies to the improved ergonomics of the automatic packaging system, which makes employee work more comfortably. Besides they have more time to feed the empty cases into the Virtuo thanks to the extended conveyor belt Among other things, they have more time to

feed the empty CASES in the Virtuo thanks to the extended conveyor belt. Also, the working height of the machine has been adapted, making it easier for packaging personnel to handle the cases. The Virtuo is equipped with the IN3 Box Turner, which provides greater flexibility in positioning the boxes into the cases. The bag-in-box products are turned to the left or go directly through the Box Turner if rotation is not necessary. In these and all other aspects, the machine meets every need of Box Marche when it comes to packaging these products.

Another Ergosa is coming?

In addition to protective sleeves and bag-in-box products, Box Marche produces a variety of different types of packaging for brand manufacturers. Depending on the production requirements, they are processed from the folder-gluer line with the Ergosa or from the Virtuo Automatic Packer. Both packaging machines offer the required degree of flexibility.

At the beginning of 2020, Box Marche will install a third folder-gluer for the production of straight line boxes and auto- bottom boxes. This line will probably be equipped with an Ergosa C Universal Packer. The company needs a third folder-gluer line to support its growth and to be able to use the two existing folder-gluer lines exclusively for the production of sleeves and bag-in-box packaging.

“Today we must provide our customers with integrated packaging solutions that offer them real added value. This applies, for example, to innovative functions for security or protection of products that allow our customers to differentiate themselves on the market”, says Dominici. Since 2003, Box Marche documents its work every year in its “Living Company Report”, which reflects the measure in which the company shows respect for its employees, customers and suppliers, for the environment and for territory. “We are a company with a soul. As if we were only one person”, says Dominici. On the occasion of the company’s 50th anniversary, the Living Company Report for 2019 included almost 170 pages.

Business organization based on the Japanese model

Dominici organized his company according to the most modern management methods. In doing so, he’s inspired by the principles of the Toyota Production System (TPS), which aims to achieve the maximum productivity with high quality and punctual deliveries. Box Marche ‘s investment in Impack packaging lines fits into this picture, as it ideally supports all three objectives of TPS. Sleeves are generally delivered to the customer within five days, with a maximum delivery time of ten days for folding boxes and corrugated cardboard packaging.

The combination of technical performance and partnership orientation is well received by the market. Over 90% of the approximately 100 customers remain loyal to the company in the long term. Dominici sees growth potential for his company in Germany, France and Great Britain. In this context, Box Marche exhibited at FachPack 2019 in Nuremberg together with the Italian manufacturer of packaging, Lucaprint.

Box Marche S.P.A., with headquarters in Corinaldo in the province of Ancona in the Marche region, which now has 55 employees, was founded in 1969 by several partners in the agricultural, commercial and industrial sectors with the mission of producing cardboard boxes for the manufacturers of footwear and slippers, widespread in those years in the province of Macerata in the Marche. After the gradual migration of footwear production to other regions of the world, the growing packaging manufacturer has shifted its focus to food, beverage and cosmetics sectors. Starting in the early 1980s also pharmaceutical products, fashion accessories and household items. Since then he won numerous awards with his innovative packaging ideas, including several ECMA PRO CARTON Awards. About 10% of Box Marche products is delivered abroad, for example in Denmark and Sweden. The current administrator delegate and owner of Box Marche, Tonino Dominici, joined the company in 1974 on behalf of the owners to lead the company towards a successful future. Someday it will be his son Nicola to continue his work.

Box Marche S.P.A., with headquarters in Corinaldo in the province of Ancona in the Marche region, which now has 55 employees, was founded in 1969 by several partners in the agricultural, commercial and industrial sectors with the mission of producing cardboard boxes for the manufacturers of footwear and slippers, widespread in those years in the province of Macerata in the Marche. After the gradual migration of footwear production to other regions of the world, the growing packaging manufacturer has shifted its focus to food, beverage and cosmetics sectors. Starting in the early 1980s also pharmaceutical products, fashion accessories and household items. Since then he won numerous awards with his innovative packaging ideas, including several ECMA PRO CARTON Awards. About 10% of Box Marche products is delivered abroad, for example in Denmark and Sweden. The current administrator delegate and owner of Box Marche, Tonino Dominici, joined the company in 1974 on behalf of the owners to lead the company towards a successful future. Someday it will be his son Nicola to continue his work.