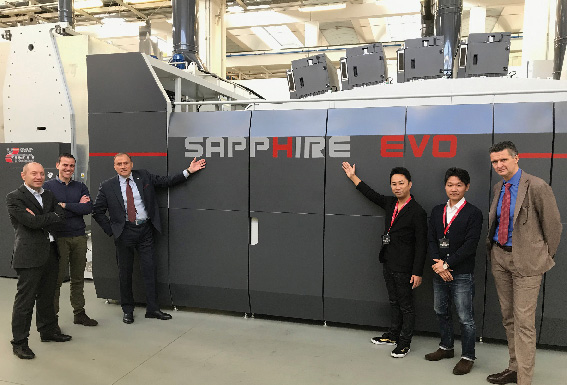

Uteco Group announces the order confirmation for the new Sapphire Evo, an hybrid digital solution. This order, carried out in Japan by Kinyosha, brings the total sales to 3 units worldwide, which constitute, in agreement with customers, the centers of Technological Excellence of Digital by Uteco-Kodak in the various macro-areas in the world.

Uteco Group announces the order confirmation for the new Sapphire Evo, an hybrid digital solution. This order, carried out in Japan by Kinyosha, brings the total sales to 3 units worldwide, which constitute, in agreement with customers, the centers of Technological Excellence of Digital by Uteco-Kodak in the various macro-areas in the world.

After the announcement last year before the Print4All international fair, which saw the second sale to an important Italian customer, now arrives the confirmation of the third unit, a result achieved within the first eight months of the commercial availability of the machine.

“The sale of the third Sapphire Evo unit in the world confirms the high level of interest that we have seen during the open house coinciding with Print4All”, comments Aldo Peretti, Group president and CEO Shareholder, Uteco. and President of Confindustria/Acimga. “Both printers have been impressed with quality and productivity, and we are confident that the introduction of the new machinery to support their businesses will help them reap the rewards with the new print applications available, making more profit”.

“The printing process developed is mature and the confirmation of the third unit gives us even greater conviction that the path taken with Uteco is the right one”, says Riccardo Passerini, Kodak’s Sales Director Mediterranean & Balkans Regions, who briefly explains how the system works: “Kodak Prosper Stream uses a different approach because it does not include electrostatic charges, but uses a proprietary printing system based on the thermal” pinch-off “of continuously emitted ink streams, for fast, accurate and reliable printing.

By applying a regular pulse to the heaters surrounding each nozzle orifice, the ink is stimulated to divide into very fine droplets. The heads are always clean and this is why printing can take place quickly, because the ink flows continuously, unlike other inkjet technologies where the nozzle opens, closes and reopens”, explained Passerini.

The Japanese company Kinyosha with Sapphire Evo will be able to produce food packaging at high speeds, increasing its offer and the customer base.

Digital printing was created to serve the needs of flexible packaging, in addition to paper, personalized and interactive that will grow more and more. Big brands started but now it is becoming a widespread need and you can see every day: the special packaging for special occasions, the small circulation to test the liking of a new product line, the mandatory information that constantly changes and contribute to fragmenting the batches of printed packaging… there are many reasons that suggest the converter to gear up to meet this demand.

The machine developed by Uteco, already presented as a prototype at last drupa 2016 in the Sapphire version, is a four-color inkjet hybrid printing machine, able of printing webs of 650 mm width in a single pass, with a mechanical speed of 300 m/min.

It uses 4 printheads (ready for the 5th) with Kodak Stream technology to obtain resolutions of 200 lpi with water-based inks (9μm the size of the single drop), thanks to this combination, the four-color printing can cover a gamut that is much wider than standards, which other technologies can only do using 7 colors printing. This printing machine is designed to raise the quality threshold that can be achieved with a digital printing system.

For example, it is important the possibility that the machine offers, by applying a primer before printing and thanks to the gravure unit, to print on paper and plastic films such as PP, BOPP, PE and PET and to apply a water-based protective coating before winding passing in the flexo unit. The new machine will be installed in November this year.

Kinyosha Ltd. Co is a Japanese company based in Tokyo that produces flexible packaging for a wide range of food and multimedia industries for over 50 years. It focuses in particular on support for local businesses; as a result, the runs are short and repetitive.

A machine with reduced start-up times and high productivity is what the company needs.

Home Converter – Flessibili – Carta – Cartone Uteco Group confirms the sale of the third digital machine Sapphire Evo...