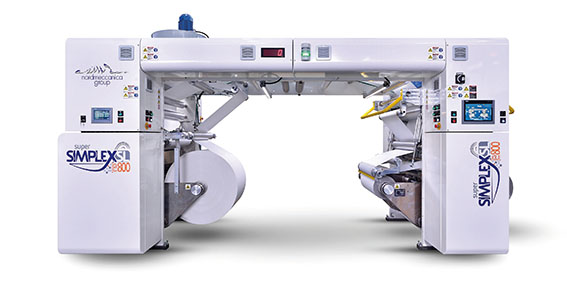

Nordmeccanica launched a new, solventless lamination solution designed especially for on-demand, flexible packaging production on HP Indigo digital presses. Developed in collaboration with HP Indigo, the Super Simplex e800 Laminator is an innovative system optimized for the HP Indigo 20000 Digital Press.

The 800 mm wide Nordmeccanica Super Simplex e800 Laminator is a solventless laminator, offering innovation in energy consumption and waste, designed to answer the growing need for converters to deliver on-demand, flexible pouches and move toward a sustainable solution.

“We are very pleased for being selected by HP Indigo as a technology partner to develop the growing flexible packaging market. Our joint effort will no doubt benefit our mutual customers. This collaboration has been key in creating a first-class solution that is both environmentally friendly and highly productive,” said Antonio Cerciello, President, Nordmeccanica.

The 762 mm (30 inch) HP Indigo 20000 can print on-demand virtually any sized flexible packaging application with unlimited variation and support demand for growing SKUs.

The Nordmeccanica Super Simplex e800 Solventless technology offers unprecedented advantages in both productivity and profitability, thanks to lowered energy consumption with no emissions and requiring no drying system. The ability, through lamination, to protect the print and increase mechanical and chemical performances, improves the value of the finished package and widens the ability of converters to grow while serving their customers.

“This combined HP Indigo and Nordmeccanica solution broadens the HP Indigo Digital Pouch Factory solution for flexible packaging enabling converters and brands to move toward on-demand, sustainable packaging solutions,” said Alon Bar-Shany, general manager, HP Indigo.

The new Nordmeccanica laminator is already operational at ePac Flexible Packaging, serving as the launch customer for the solution as it rapidly expands its on-demand packaging services globally.