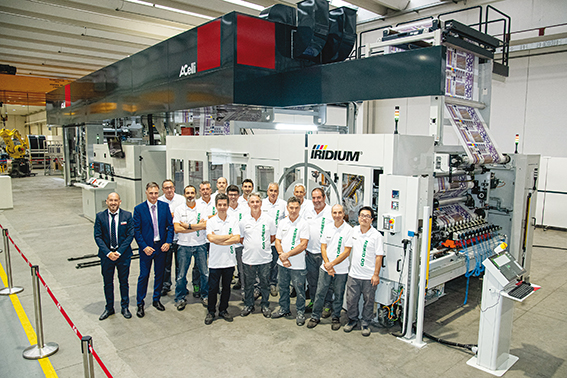

Leader in the tissue sector, the Tuscan company, backed by first-rate technological know-how, has chosen Claudio Bisogni to take the big step into the flexible packaging market. Last October an open house in its Lucca plant unveiled the new CI flexo machine in front of a wide audience of operators

It does not happen every day to assist a manufacturer who decides to look out onto a new market, which is already well guarded by well-known operators both nationally and internationally, a choice that is certainly brave for A.Celli’s management, but in line with its great awareness in their own abilities and above all in the proposed technological solutions.

No coincidence that the title of the open house speaks of a revolution in flexo printing and the new Iridium® printing machine will have to play the role of the protagonist.

Furthermore, the decision to entrust the responsibility for the development of the new product division focused on printing and coating processes in the hygienic-sanitary sectors, paper, flexible packaging to Ing. Claudio Bisogni is another equally strong and distinctive sign of the Tuscan manufacturer’s intentions: rapidly climbing positions in the market, to achieve a leadership role, universally recognized by the tissue market.

The event organized last October, coinciding with the Miac of Lucca, the most important event in Italy for the tissue market, (let’s not forget that we are in the Tissue-Valley, and in this area there are numerous paper mills and machinery and technology producers for this industry), attracted numerous operators from the hygienic-sanitary sector to the modern and new factory of A.Celli, as well as obviously flexible packaging printers interested in discovering and touching the potential of the new machine .

A new machine, the Iridium® that was born out of a specific request from a Chinese customer, interested in printing with a very thin and breathable material, the inside of diapers for children, a new and unusual application, destined to revolutionize this market. I also changed some diapers, and honestly I don’t remember ever seeing a diaper printed internally, but it seems that in China it is a very interesting trend, so much so that the same customer, present at the event, if everything goes as planned, is already ready to expand its fleet.

Iridium® in detail

It is well-known the delicacy of the non-woven tissue (both in the machine and out), also the dimensions of these rolls make them very fragile in handling and logistics.

It is well-known the delicacy of the non-woven tissue (both in the machine and out), also the dimensions of these rolls make them very fragile in handling and logistics.

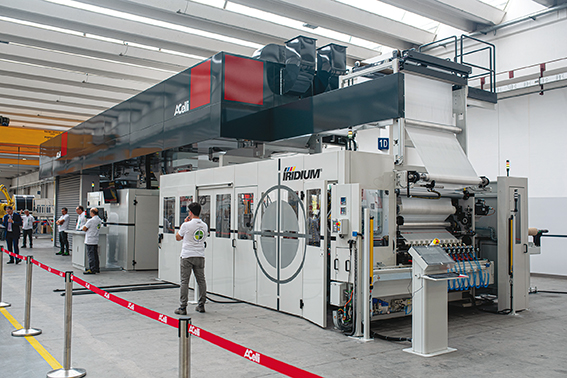

Certainly the application presented at the open house, with an extremely thin, breathable material, subject to possible deformations in the machine, has exploited the synergies of competences of A.Celli deriving from the tissue sector. Iridium® can be used for printing plastic and paper-based, health-care and obviously tissue packaging applications, it is available from 2 to 10 color units, servo-motorized, and is available both for water-based, solvent and UV inks. The printing area for the packaging machine ranges from 800 to 1600 mm, with print repeatability from 300 to 1150 mm, and is capable of reaching a maximum speed, based on the application, from 400 to 600 meters a minute.

The classic central drum configuration facilitates access to the printing elements, both for set-up and cleaning operations. The upper drying tunnel guarantees the drying of water-based inks very quickly at maximum speeds, and also reduces retention in solvent-based inks. Iridium® is also equipped with an intuitive touch-screen management system, also useful for collecting production data for a 4.0 production management, foreseeing the inclusion of the machine within a complete company production workflow, and is equipped with all the most modern automatisms present today on these printing machines: automatic positioning of the sleeves, automatic registration, automatic positioning of the inking system, automatic washing system of the components and printing plates, automatic printing pressure, control ink viscosity, web cleaning systems.

A.Celli has also developed an automated management and logistics system, which can also be applied to the flexible packaging industry, with automatic AGVs (shuttles) for the management of webs within an automated warehouse and for the automatic preparation of jobs ready for shipping. An RFID system for automatic detection of the webs is also part of this solution.

Face to face with Claudio Bisogni, Flexographic Print Sales Manager at A.Celli Group

Can you explain A.Celli’s choice to enter the CI flexo printing sector?

Can you explain A.Celli’s choice to enter the CI flexo printing sector?

“A.Celli, world leader in the non-woven sector, in hygiene products and in the tissue paper industry, has represented a technical and technological point of reference since the beginning, developing pioneering solutions, guaranteeing incomparable performance and quality and the maximum efficiency. The flexible packaging structure is evolving adapting to new needs, and consequently requiring more sophisticated technical solutions, very similar to those already successfully developed by A.Celli, which intends to reach the same leadership position in a short period of time”.

Over the past 2 years, the list of references of A.Celli on the Chinese market has grown. What is your perspective about the development of CI flexo printing in this market?

“The Chinese market worldwide is potentially the largest in terms of volumes and is rapidly becoming one of the most sophisticated and demanding in terms of aesthetics and technical characteristics (barrier properties) of the final product.

The growing awareness for environmental protection is directing the market towards processes with the least environmental impact and the CI flexo machines are the best solution to achieve this goal.

A.Celli’s ambition to quickly become a reference point also in flexo printing of flexible packaging is supported by a strong competence and consolidated experience acquired in those sectors in which the tension control of the materials, the excellent conduction without lateral drifts of the web in production and the optimal set-up of the drying system, are fundamental to guarantee high performance, quality and efficiency: thanks to the new technical characteristics that today distinguish flexible packaging, the features typical of tissue sector will become essential also in the field of flexible packaging. A.Celli is ready to win the challenge”.

Based on the vast experience in the CI flexo industry, what is your view on the development trend of CI flexo printing?

“CI flexo printing is rapidly gaining a leadership position as a process applied to all the materials that characterize flexible packaging; the recent and substantial improvement in the manufacturing process of plates and anilox, the new technical solutions introduced by machine suppliers, the availability of water-based inks, the development of new technologies such as EB and UV LED printing, make CI flexo printing the most effective, efficient and environmentally friendly process.

“CI flexo printing is rapidly gaining a leadership position as a process applied to all the materials that characterize flexible packaging; the recent and substantial improvement in the manufacturing process of plates and anilox, the new technical solutions introduced by machine suppliers, the availability of water-based inks, the development of new technologies such as EB and UV LED printing, make CI flexo printing the most effective, efficient and environmentally friendly process.

Companies, public institutions, individuals and governments are now aware of the importance of preserving the environment, limiting pollution and protecting nature. Flexo printing helps to achieve these needs; A.Celli’s CI flexo machines allow the recovery of thermal and electrical energy during the process, they guarantee a higher production speed without vibrations, they use indifferently of conventional cliché carrying sleeves, and directly engraved, and therefore without interruptions, they can be configured with different technologies, becoming effective hybrid machines with minimum environmental impact”.

Water or solvent based inks?

“A.Celli is at the forefront in the process of water based inks, following the market trend of using the ‘ecological thinner’ instead of the solvent.

“A.Celli is at the forefront in the process of water based inks, following the market trend of using the ‘ecological thinner’ instead of the solvent.

Printing with water-based ink is more difficult than with solvent: the evaporation of water requires more thermal energy and a greater amount of air than the solvents used to dilute the inks. Furthermore, the chemistry of water-based inks requires special solutions for the inking system, in order to avoid foaming problems.

A.Celli has developed unique solutions for high-speed printing with water-based inks, even on critical materials, thanks to its long and deep expertise and its know-how, combined with consolidated relationships with the most advanced ink suppliers”.